Rotor of rotary electric machine

A technology for rotating electrical machines and rotors, applied in the field of rotors of rotating electrical machines, can solve the problems of increased motor manufacturing costs and complicated manufacturing processes, and achieve the effects of improving torque performance, maximizing demagnetization resistance, and increasing demagnetization resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Embodiments of the present invention will be described below based on the drawings. It should be noted that the drawings are views viewed along the direction of symbols.

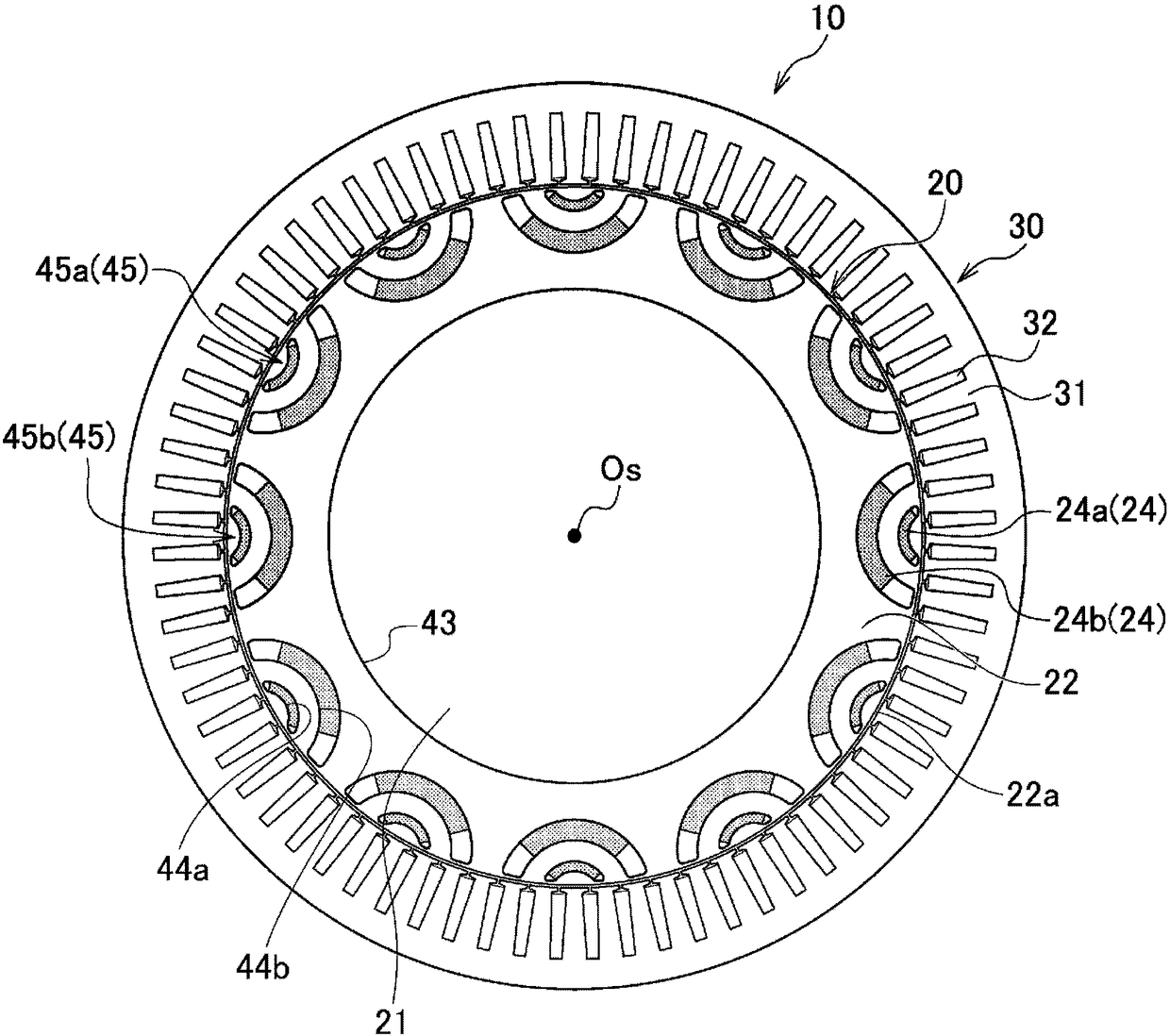

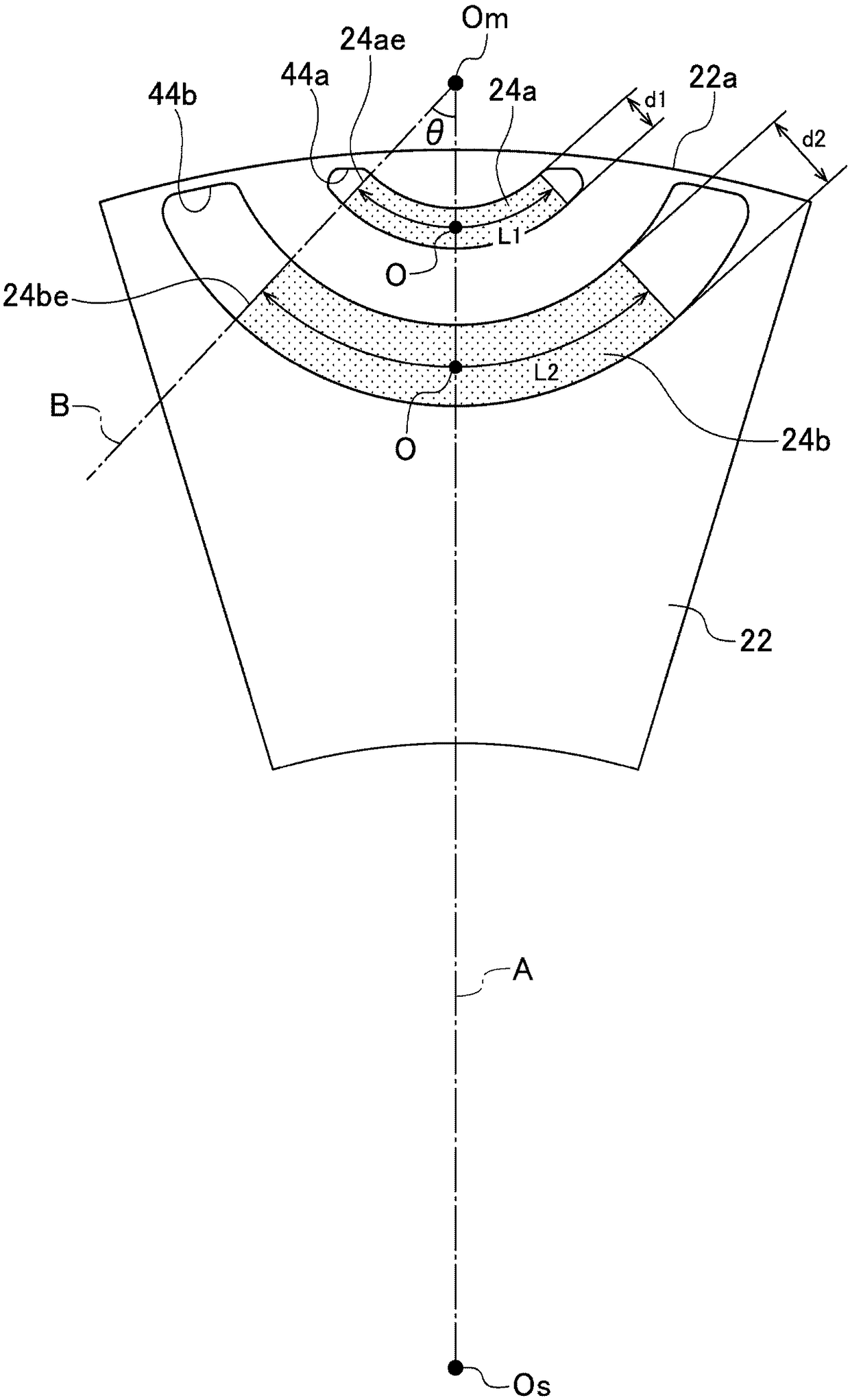

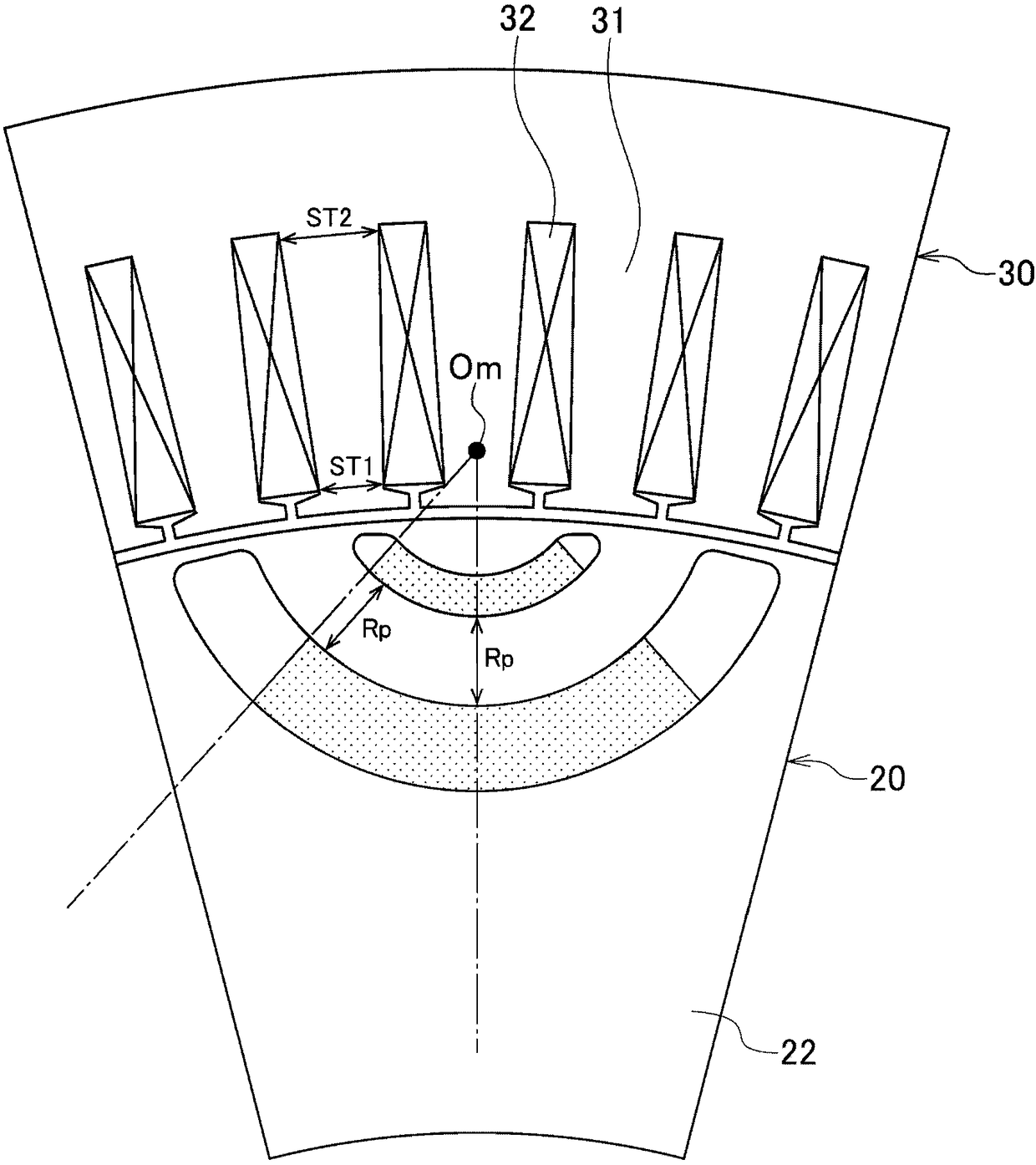

[0057] figure 1 It is a radial cross-sectional view of the rotating electrical machine according to one embodiment. figure 1 The illustrated rotating electrical machine 10 includes a rotor 20 and a stator 30 disposed opposite to each other with a slight gap on the radially outer side of the rotor 20 . The rotating electrical machine 10 is configured to rotate the rotor 20 by energizing the coil 32 wound around the teeth 31 of the stator 30 .

[0058] The rotor 20 is a rotor of a so-called embedded permanent magnet rotating electrical machine (IPM motor), and has a rotating shaft 21 rotatably supported by a not-shown frame, a rotor core 22 fixed to the outer peripheral surface of the rotating shaft 21, And a plurality of permanent magnets 24 embedded in the rotor core 22 .

[0059] The rotor core 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com