Camera assembly of electronic equipment and electronic equipment

A technology of camera components and electronic equipment, applied to color TV parts, TV system parts, electrical components, etc., can solve the problems of difficult installation, long time spent, complicated installation process, etc., and achieve simple assembly , improve assembly efficiency, and achieve the effect of fixed connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

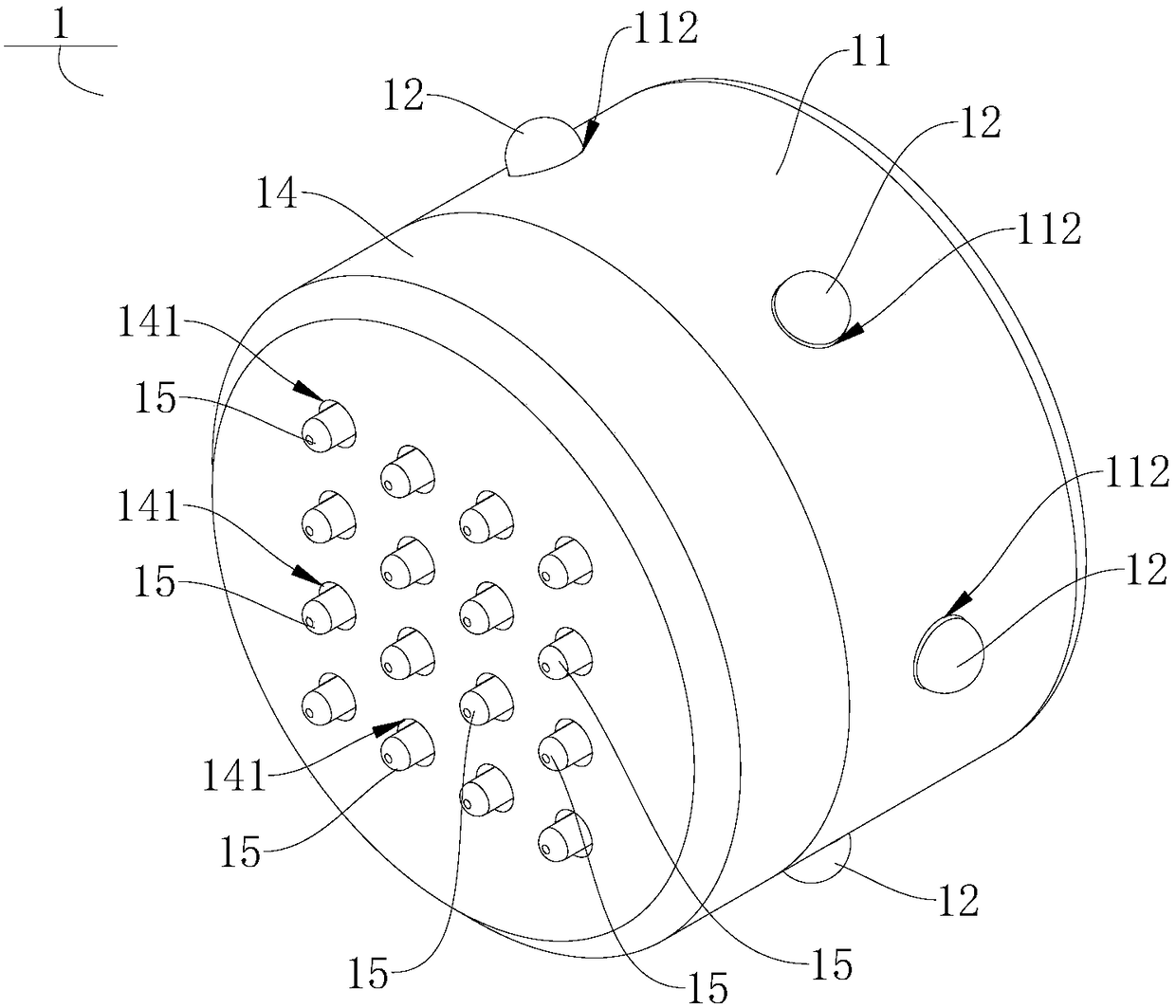

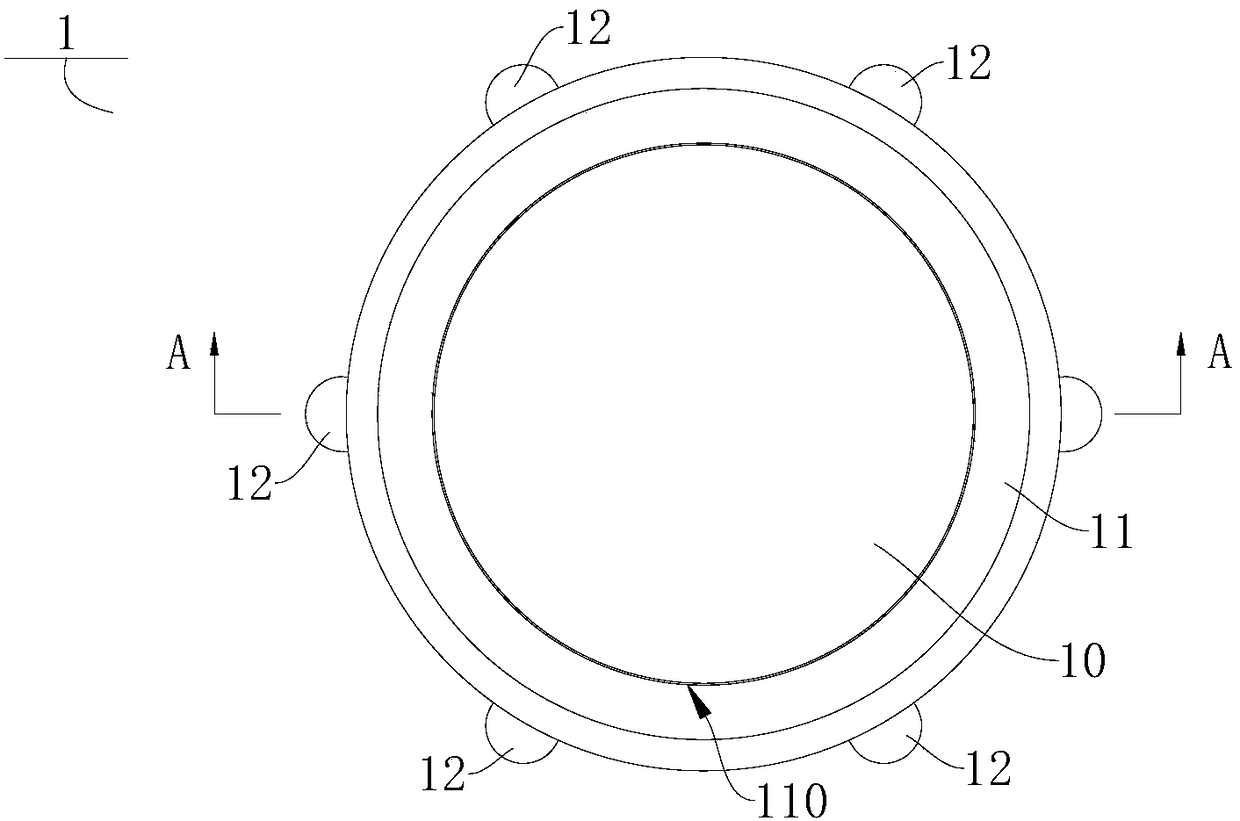

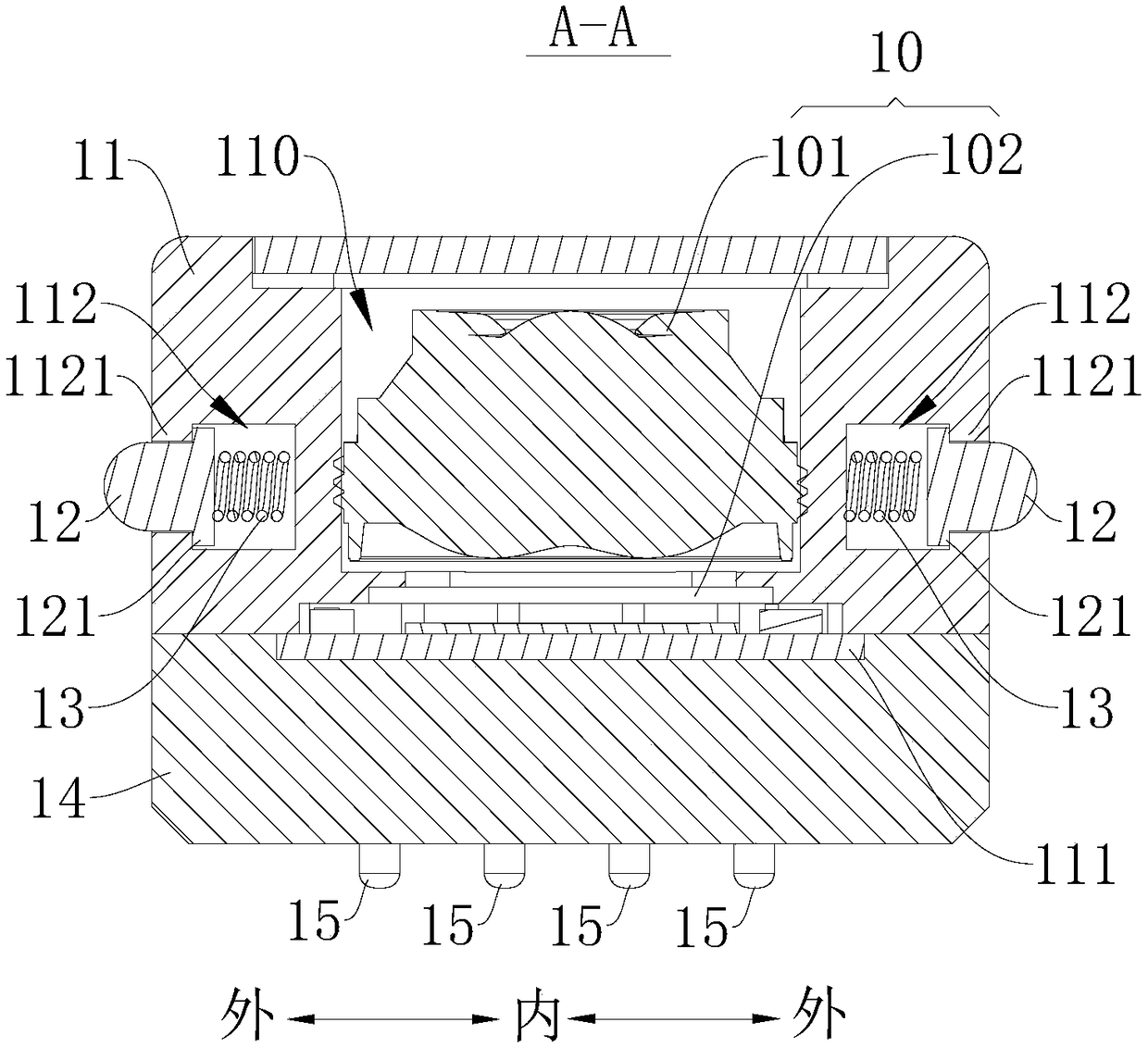

[0065] Such as figure 1 , image 3 and Figure 4 As shown, the camera assembly 1 includes: a lens assembly 10, a bracket 11, a limit block 12, an elastic member 13 and a fixing frame 14, the bracket 11 is configured as a cylinder, the bracket 11 has an installation cavity 110, and the lens assembly 10 is located in the installation cavity within 110. The lens assembly 10 includes: a lens 101 and a photosensitive chip 102 .

[0066] Such as image 3 and Figure 4 As shown, the outer peripheral wall of the bracket 11 is provided with a plurality of installation holes 112 evenly spaced along the circumferential direction of the bracket 11 , and the plurality of installation holes 112 are located in the same height plane of the bracket 11 . A limiting block 12 is arranged in the mounting hole 112 , and the end surface of the limiting block 12 away from the bottom wall of the mounting hole 112 is a hemispherical surface, and the limiting block 12 can cooperate with the limitin...

Embodiment 2

[0070] The structure of this embodiment is substantially the same as that of Embodiment 1, wherein the same components use the same reference numerals, the difference is that a plurality of spring pins 15 are arranged at intervals on the circuit board 22, and the bracket 11 is provided with The circuit board 22 and the camera assembly 1 are electrically connected through the cooperation of the spring pin 15 and the contact 16 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com