Seed protection groove assisting garlic bulbil direction control, device, planting machine and method

A technology of direction control and scale buds, which is applied in the direction of interval quantitative sowing machinery and planter parts, can solve the problems of limited mechanical planting, poor uniformity, and increased planting risks, and achieve the effect of self-breaking the soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] As introduced in the background technology, there are deficiencies in the prior art. In order to solve the above technical problems, this application proposes a device for controlling the direction of garlic buds.

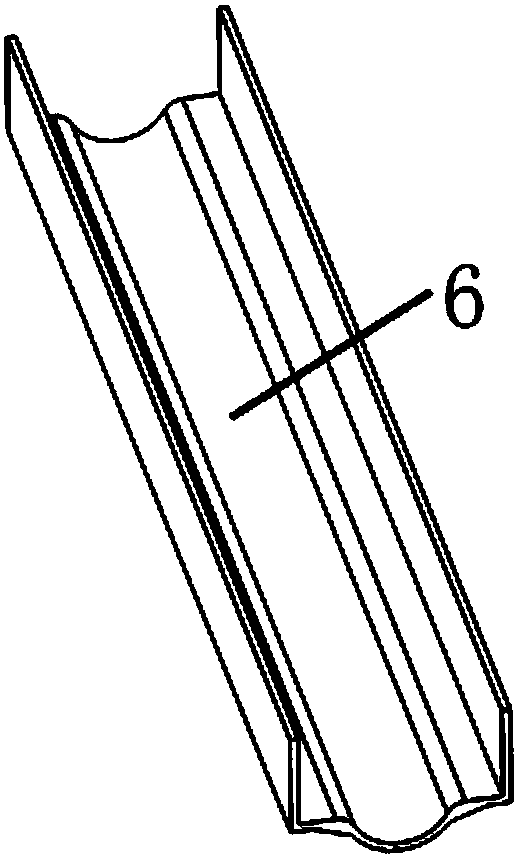

[0052] In a typical implementation of the present application, such as image 3 and Figure 4 As shown, a garlic scale bud direction control device, the seed protection groove is arranged on the side of the inclined downward section of the scale bud direction control chain 1, the seed protection groove is arranged on the frame, and the inner lower surface of the seed protection groove 5 has an edge The draw-in groove 6 arranged along the length direction of the seed-protecting groove, the bottom of the draw-in groove 6 protrudes to the outside of the seed-protecting groove 5 .

[0053] Above-mentioned scale bud direction control device, through the setting of draw-in groove 6 along the length of the seed protection groove 5, utilizes the center of gravity o...

Embodiment 2

[0060] In order to overcome the deficiencies in the prior art, the present invention also provides a garlic bud direction control device, which includes a bud direction control chain, and the bud direction control chain is distributed with garlic spoons adapted to garlic cloves, and the bud direction control One side of the chain is provided with a seed box 7, and the scale bud direction control chain passes through the bottom of the seed box 7, and the inclination of the scale bud direction control chain 1 is provided with a seed protection groove 5 in the lower section, and the lower surface of the seed protection groove 5 has a The draw-in groove 6 arranged along the length direction of the seed protection groove, the bottom of the draw-in groove protrudes to the outside of the seed protection groove.

[0061] Wherein, the distance between the head of the garlic spoon and the bottom of the slot is less than or equal to the thickness of the garlic cloves, and the shape of the...

Embodiment 3

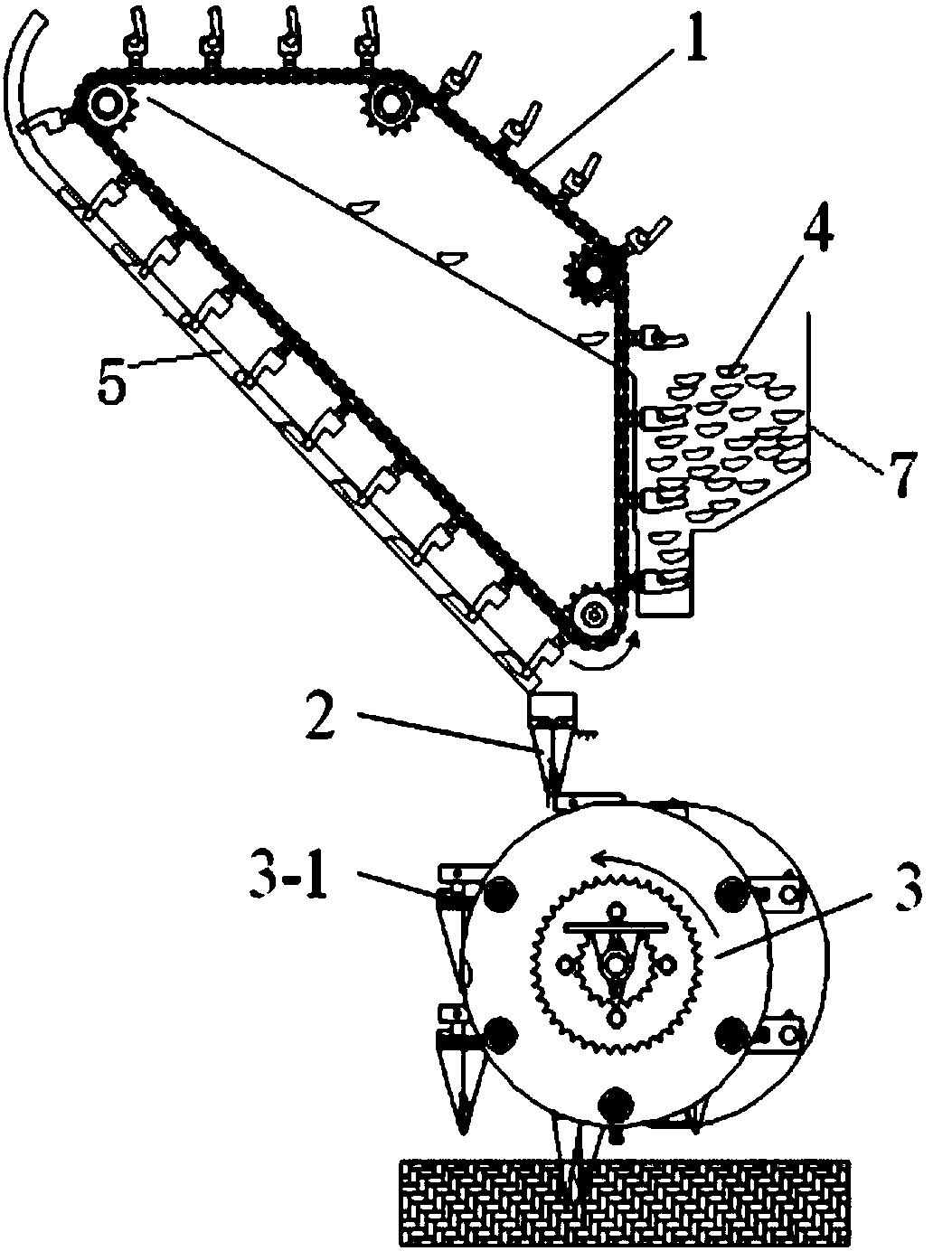

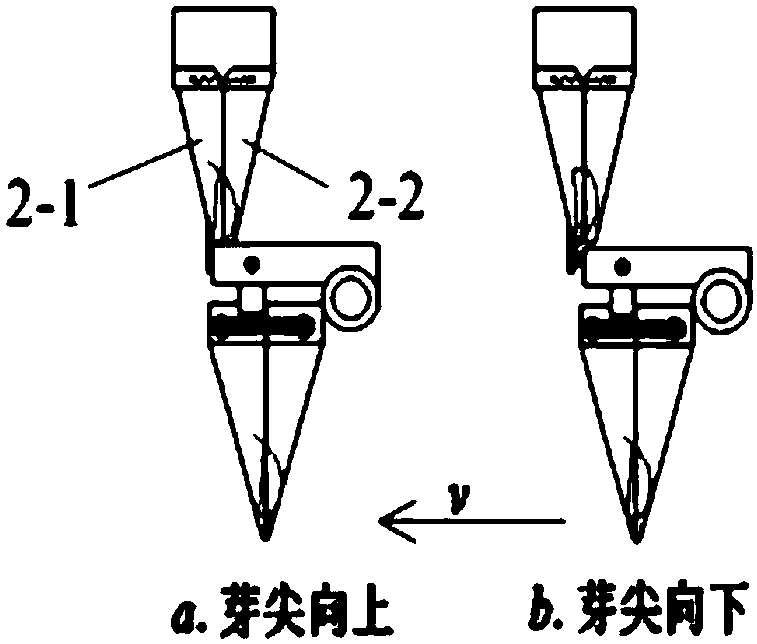

[0064] In order to overcome the deficiencies in the prior art, the present invention also provides a kind of garlic planting machine, such as figure 1 Shown, comprise a kind of garlic scale bud direction control device described in embodiment 2, the direction control cup 2 that is fixed on frame is set at the bottom of seed protection groove 5, and planting mechanism 3 is set at the bottom of direction control cup, and planting mechanism 3 comprises A plurality of garlic planting cups located on the rotating parts, the direction control cup 2 and the garlic planting cup 3-1 respectively include a fixed part and a movable part, the movable part can be opened or closed relative to the fixed part, and the direction control cup movable part 2-2 The bottom can be set in contact with the collision cup 3-2, wherein an elastic member such as a return spring 2-4 is arranged on the side of the direction control cup to realize the connection between the direction control cup fixed part 2-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com