Automatic pipe cutting machine and operation method

A pipe cutting machine and automatic technology, applied in metal sawing equipment, sawing machine equipment, metal processing equipment and other directions, can solve the problems of low production efficiency, high production cost, poor product quality, etc., to improve production efficiency, simple structure, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

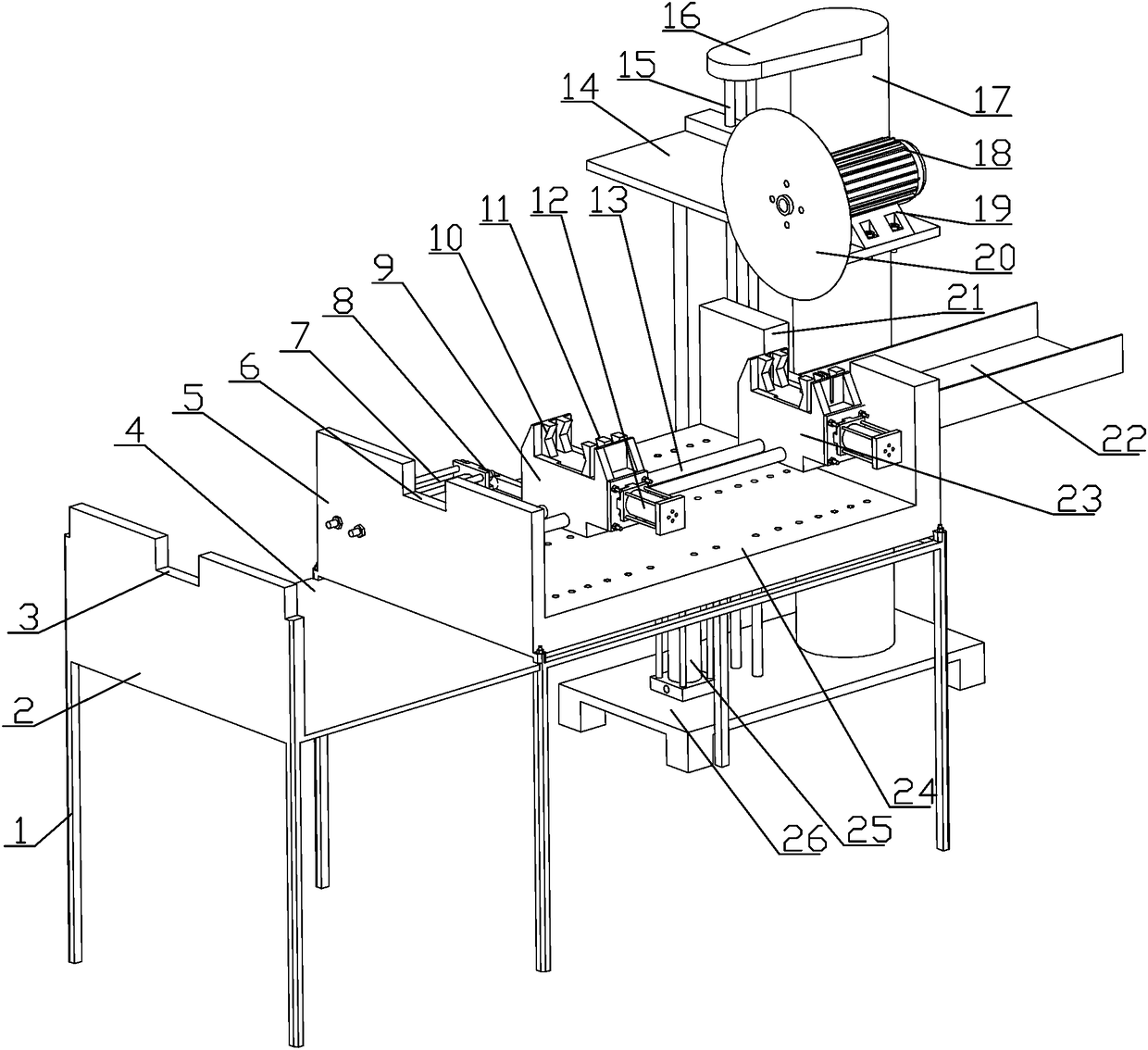

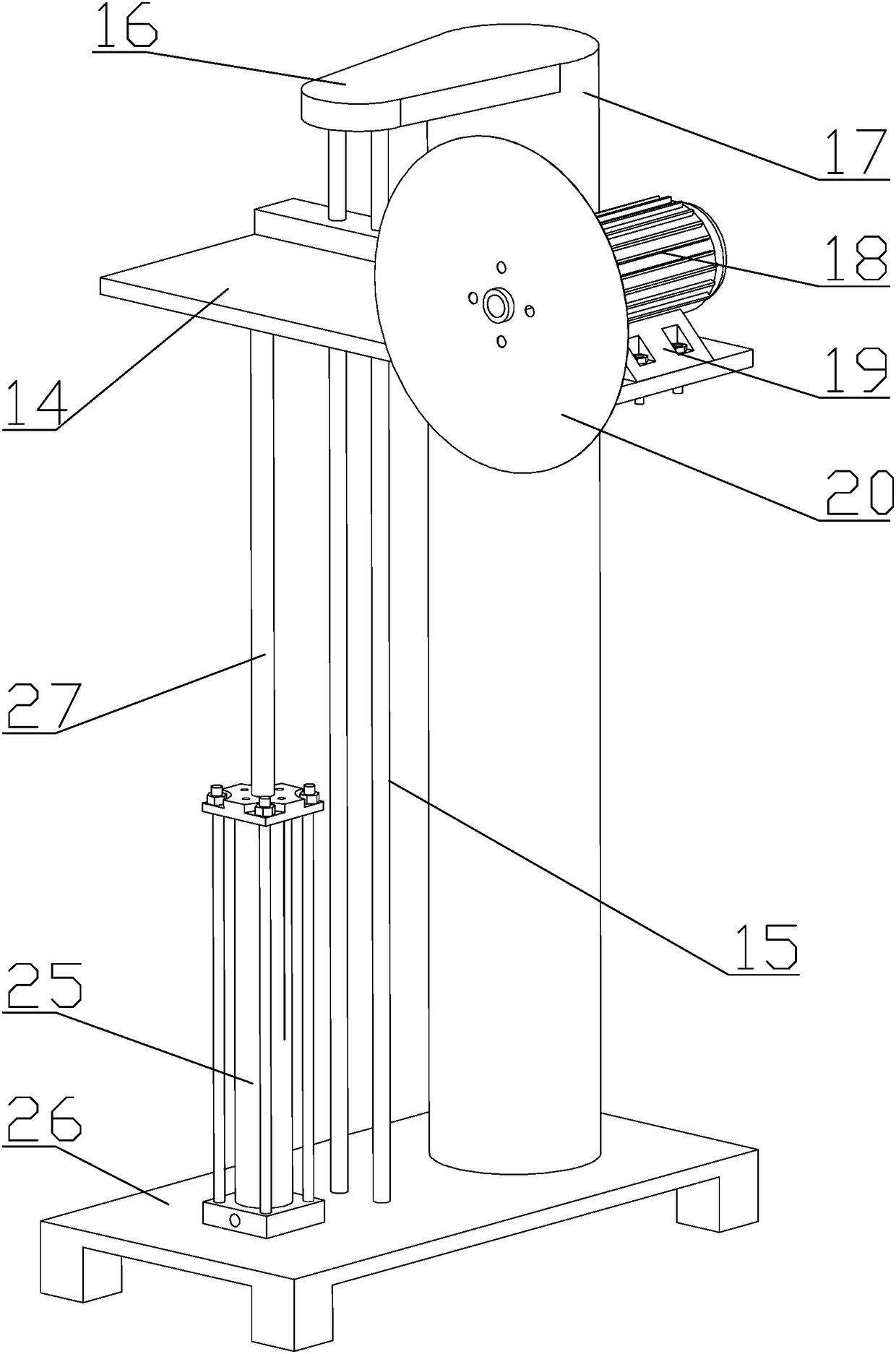

[0032] see Figure 1-2 , an automatic pipe cutting machine, which includes a frame 1, a first platform 4 and a second platform 24 are fixed on the top of the frame 1, and a support assembly for supporting pipe fittings is arranged on the first platform 4, The second platform 24 is provided with a delivery device for pushing and feeding the pipe fittings, and a fixed clamping device 23 for clamping and fixing the pipe fittings is installed at the end of the delivery device. Cutting device for pipe cutting. By adopting the automatic pipe cutting machine with the above structure, it can be used for automatic cutting of metal pipe fittings. During use, it is only necessary to place the metal pipe fittings on the top of the frame 1, and transport them through the conveying device to reach the set value. The cutting length is fixed by the fixed clamping device 23, and finally, it is automatically cut by the cutting device, thereby improving work efficiency, increasing the degree of...

Embodiment 2

[0043] The operating method of any one of the automatic pipe cutting machines, comprising the following steps:

[0044] Step1: Place the pipe to be cut on the top limit grooves of the first support plate 2 and the second support plate 5, and place the end of the pipe between the fixed clamp 10 and the movable clamp 11 of the feeding clamping device between;

[0045] Step2: Start the clamping cylinder 12 of the feeding and clamping device to clamp the pipe fittings;

[0046] Step3: Start the pushing cylinder 7, drive the feeding clamping device to slide along the horizontal slide rail 13 through the pushing cylinder 7, and then transport the pipe fittings so that the other end passes through the fixed clamping device 23;

[0047] Step4: Multiple times of reciprocating control feeding and clamping device to transport the pipe fittings until the set cutting length is reached;

[0048] Step5: Start the fixed clamping device 23 to clamp and fix the pipe fittings;

[0049] Step6:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com