Main shaft bearing end cover aligning tool of wind turbine generator system and end cover adjusting method thereof

A technology for wind turbines and spindle bearings, applied to workpiece clamping devices, manufacturing tools, hand-held tools, etc., can solve problems such as seal ring quality defects, large cumulative error of component installation deviation, and economic losses, and achieve economical adjustment Low cost, low processing and manufacturing costs, and improved operational stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with specific embodiments.

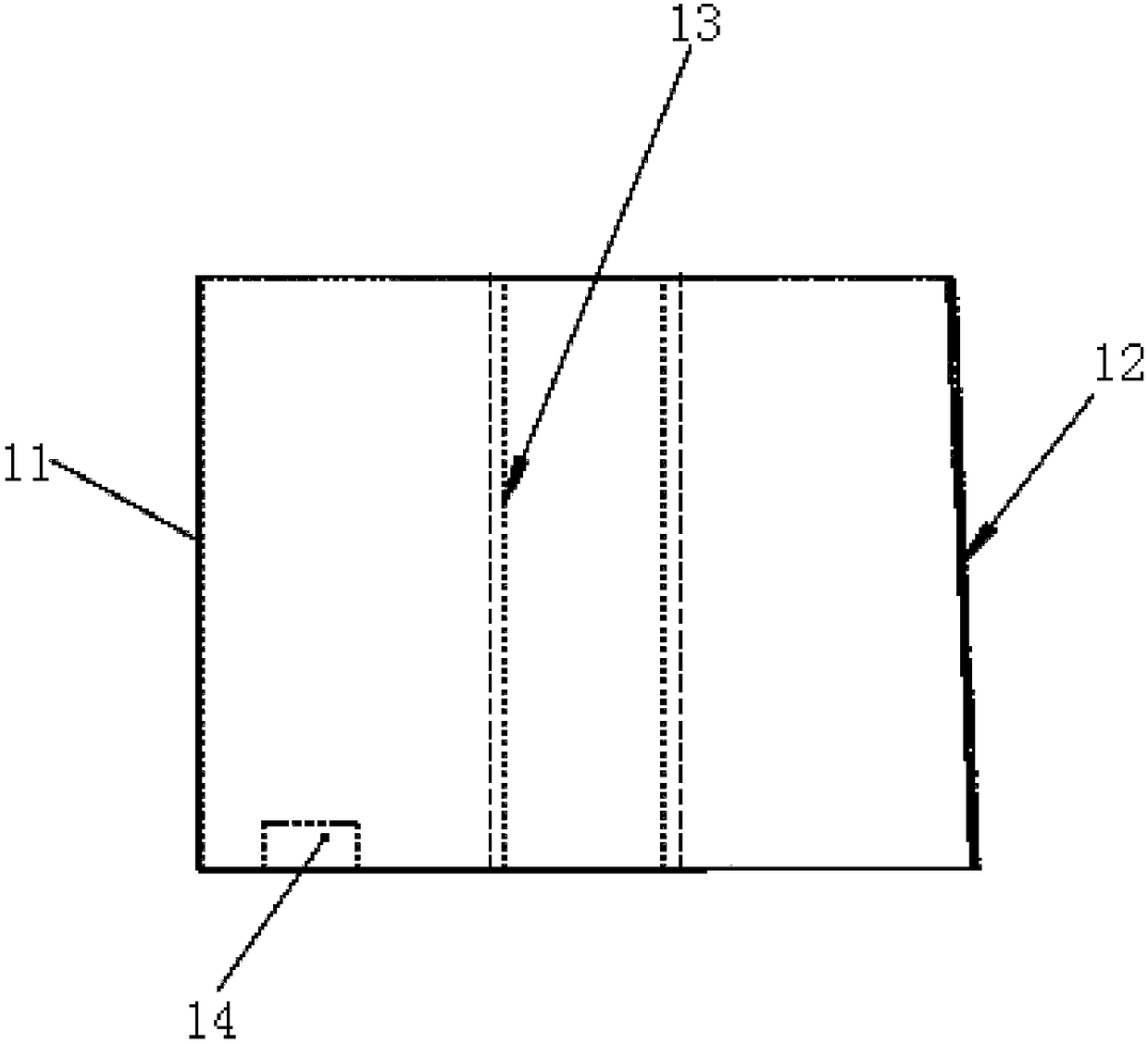

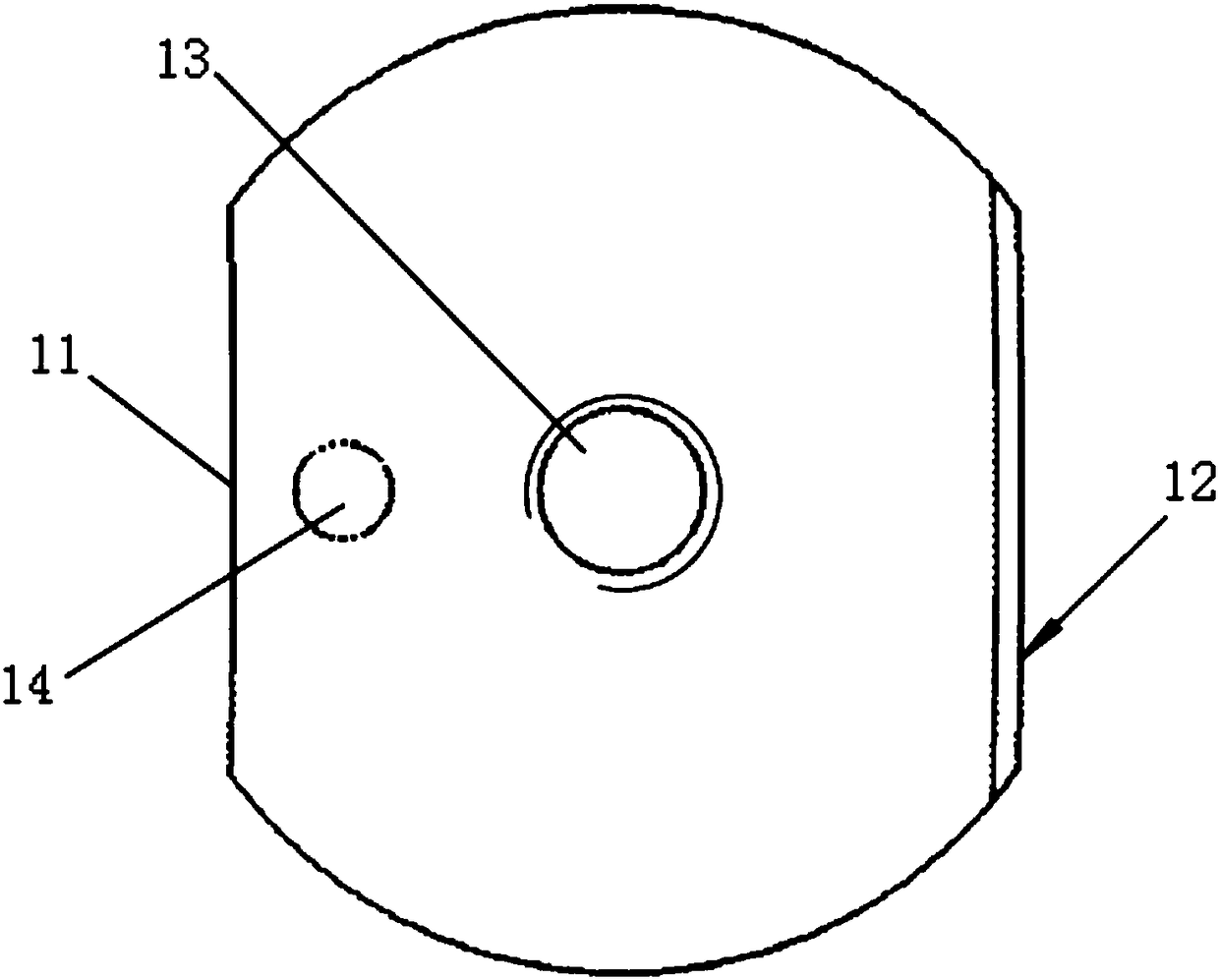

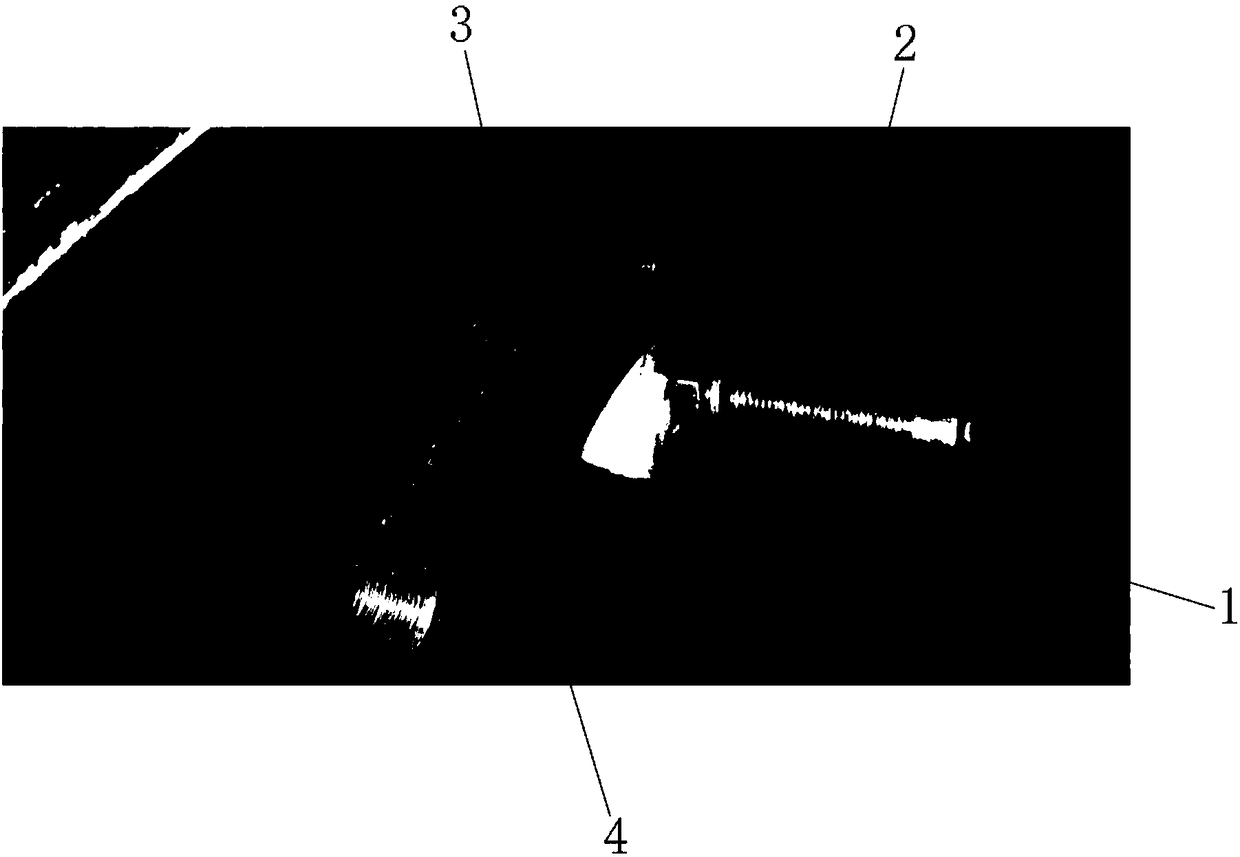

[0022] see figure 1 and figure 2 As shown, the centering tool for the main shaft bearing end cover of the wind turbine generator set provided in this embodiment is specifically an irregular circular truncated structure, wherein one side of the circular truncated structure is a plane 11 parallel to the axis of the truncated truncated, and all the The plane section 11 is vertically cut from one end face of the circular truncated cone to the other end face, and the other side of the circular truncated structure is still a tapered arc surface 12; the middle part of the circular truncated structure vertically runs through a The threaded hole 13 is on the same axis as the truncated cone, and the threaded hole 12 is matched with a screw 2 used as the handle of the circular truncated cone (see image 3 shown); the large end face of the circular truncated structure is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com