Injection molding machine insurance protection mechanism

A protective mechanism and injection molding machine technology, which is applied in the field of injection molding machines, can solve problems such as low reliability and personal injury of operators, and achieve the effects of eliminating gaps, stable cooperation, and avoiding the reduction of engagement performance

Active Publication Date: 2020-04-21

浙江亚盛建材有限公司

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, relying solely on the electric control button to control the shutdown of the machine tool is not very reliable. In the event of damage to circuit components or errors in the program, the injection molding motor may be restarted, causing personal injury to the operator during maintenance.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0014] The present invention will be described in further detail below by means of specific embodiments:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

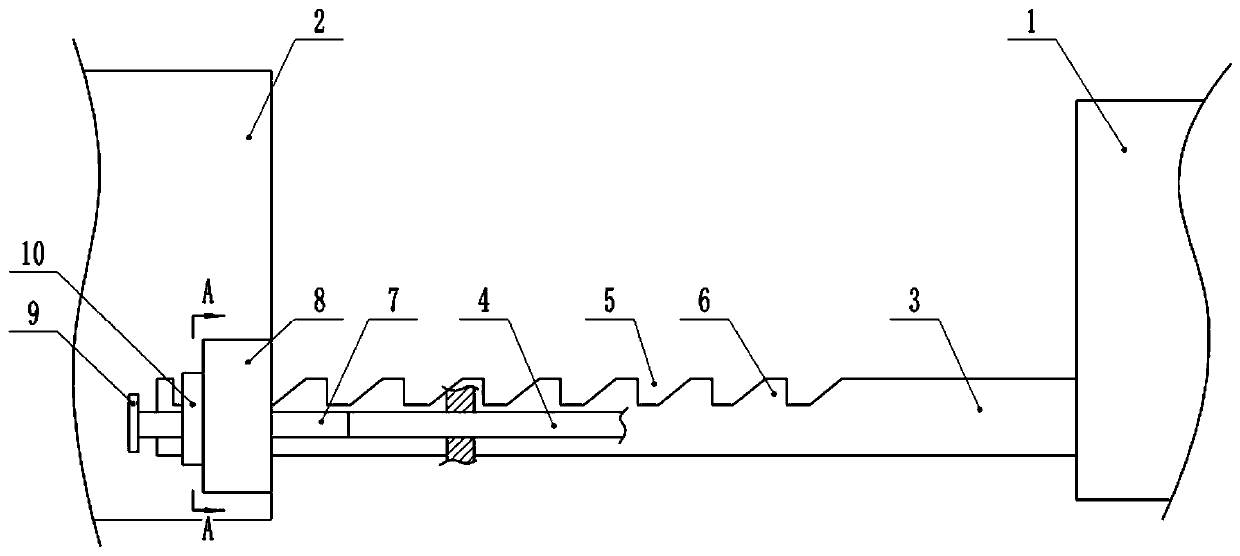

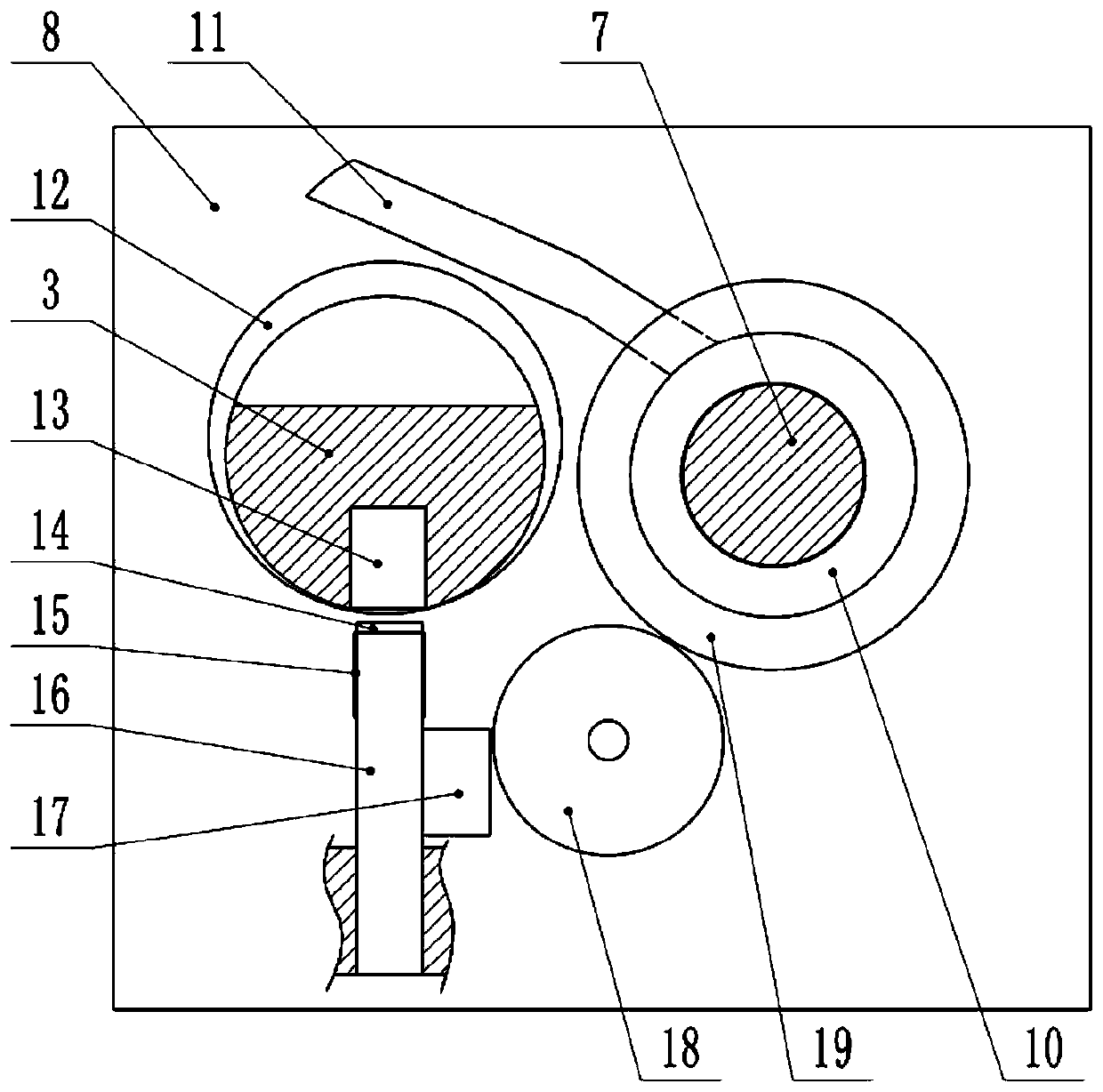

The invention belongs to the technical field of injection molding machine, and particularly discloses a safety protection mechanism of an injection molding machine. The safety and protection mechanismof the injection molding machine comprises a safety door, a bumper rod and a locking structure. A plurality of clamping grooves are formed in the upper surface of the bumper rod, and a plurality of clamping holes are formed in the lower surface of the bumper rod. The locking structure comprises a sliding rod which is slidably connected to a machine frame, and the sliding rod is fixedly connectedwith the safety door. A fixed block is fixedly arranged on a fixed wall of the injection molding machine, and a sliding hole is formed in the fixed block. A nut with a screw hole is rotatably connected to the fixed block, and a screw rod matched with the screw hole is arranged on the sliding rod. The nut is connected with a baffle block which can be clamped to a clamping groove. A first gear is arranged on the nut, and a second gear is rotatably connected to the lower portion of the fixed block. A limiting rod is slidably connected to the fixed block. A rack which meshes with the second gear is fixedly connected to the lower end of the limiting rod. When the staff opens the safety door for repair, the locking structure can be opened automatically, so that the movable wall and the fixed wall of the injection molding machine are restricted to perform spotting, and the injury to the staff is avoided.

Description

technical field [0001] The invention belongs to the technical field of injection molding machines, in particular to an injection molding machine insurance protection mechanism. Background technique [0002] The mold clamping system of the injection molding machine is mainly composed of a mold clamping device, a hinge, a fixed template, a movable template, a mold clamping cylinder and a safety protection mechanism to ensure that the mold is closed and opened. After the mold is closed, supply the mold with sufficient clamping force to resist the cavity pressure generated by the molten plastic entering the cavity, preventing the mold from opening and causing unqualified product quality. [0003] When the injection molding machine is working, it is constantly switching between opening and closing the mold. When the injection molding machine needs to be inspected and repaired, the safety protection mechanism controls the mold to be in the mold opening state. The safety protectio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B29C45/84

CPCB29C45/84

Inventor 姜锐

Owner 浙江亚盛建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com