Front parallel printing table plate movable counting and positioning mechanism

A positioning mechanism and parallel technology, which is applied to printing machines, rotary printing machines, screen printing machines, etc., can solve the problems of inability to achieve continuous multiple printing, poor repeat positioning accuracy, and affect overprinting accuracy, and achieve ingenious structural design , High repeat positioning accuracy, and the effect of eliminating errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

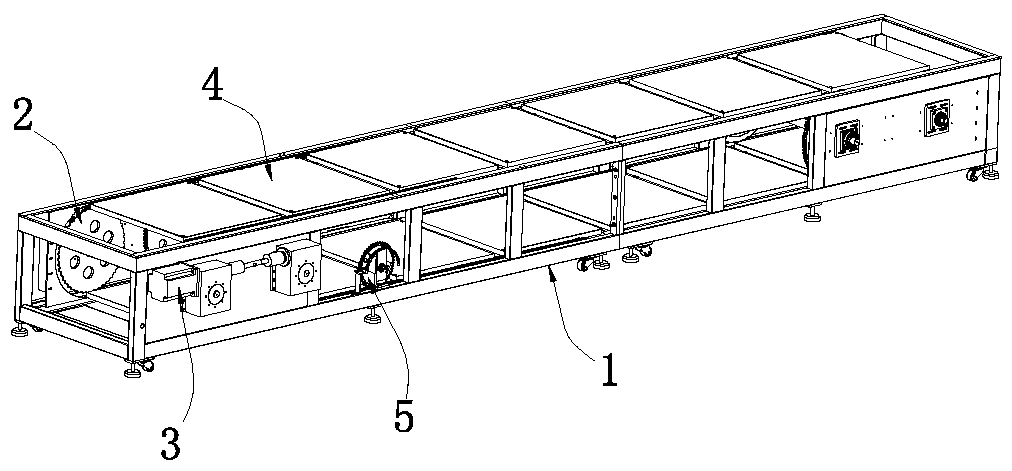

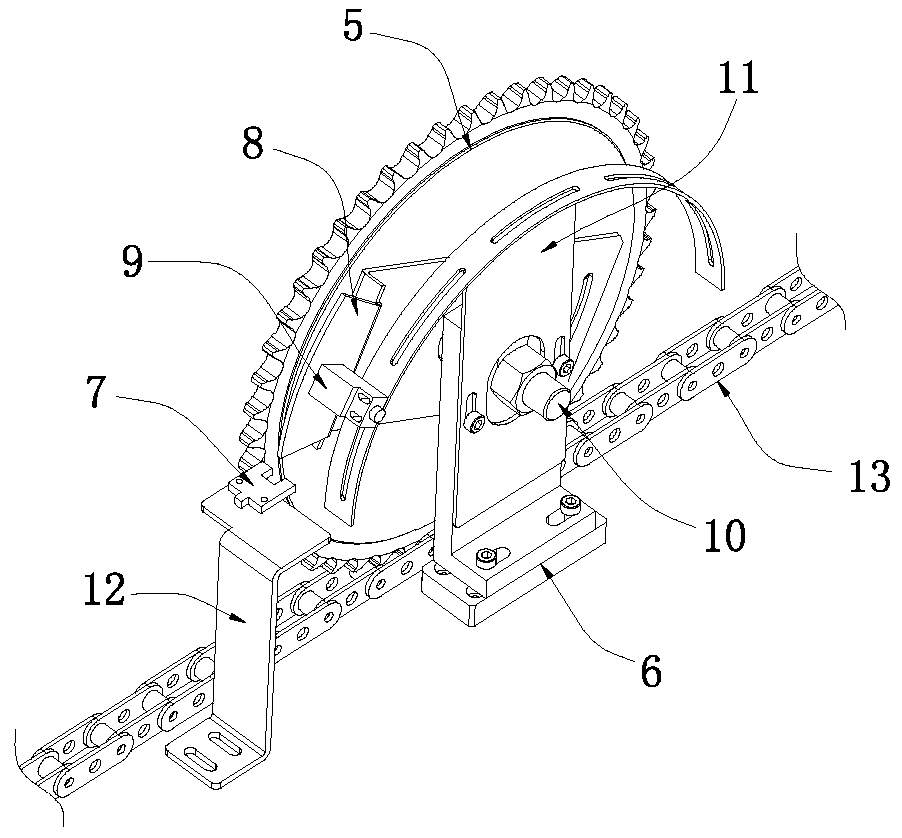

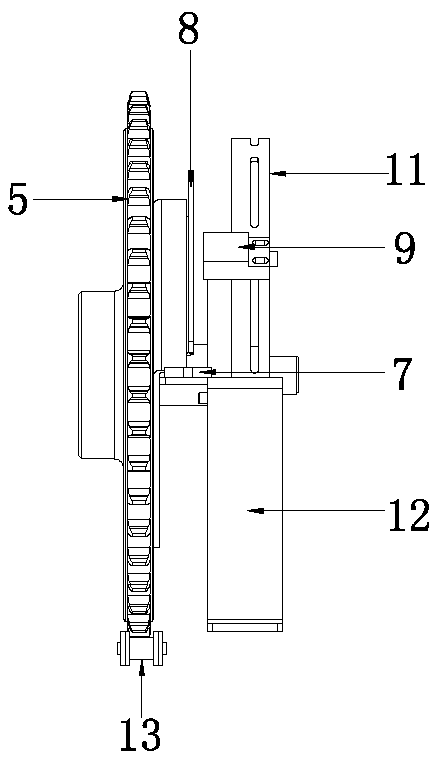

[0019] Examples, see Figure 1 to Figure 4 , the present embodiment provides a front-parallel printing platen mobile counting and positioning mechanism, which includes a frame 1, a transmission sprocket 2 arranged on the frame 1, a driving device 3 capable of driving the transmission sprocket 2 to rotate, and The transmission chain 13 that the transmission sprocket 2 is compatible with is located on the frame 1 and is dragged by the printing table 4 by the transmission chain 13, the counting sprocket 5, the sprocket bracket 6, the photoelectric switch 7, the induction plate 8 and the proximity Switch 9, the side position of sprocket bracket 6 corresponding to transmission chain 13 is arranged on the bottom of frame 1, and described counting sprocket 5 is arranged on sprocket bracket 6 by rotating shaft 10, and is connected with described transmission chain 13 meshing, the induction plate 8 is arranged on the side wall of the counting sprocket 5, and the proximity switch 9 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com