Pressure balance composite liner and manufacturing method thereof

A balance and pressure technology, applied in packaging and other directions, can solve the problems of easy damage to the seal film, container leakage, etc., and achieve the effect of simple and easy production method, good structure impact resistance, and impact resistance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] This embodiment provides a pressure-balanced composite gasket and a manufacturing method of the pressure-balanced composite gasket.

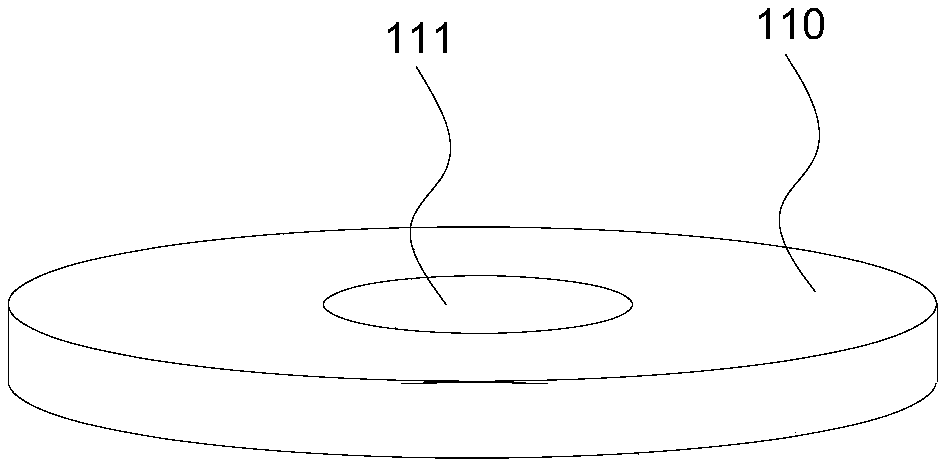

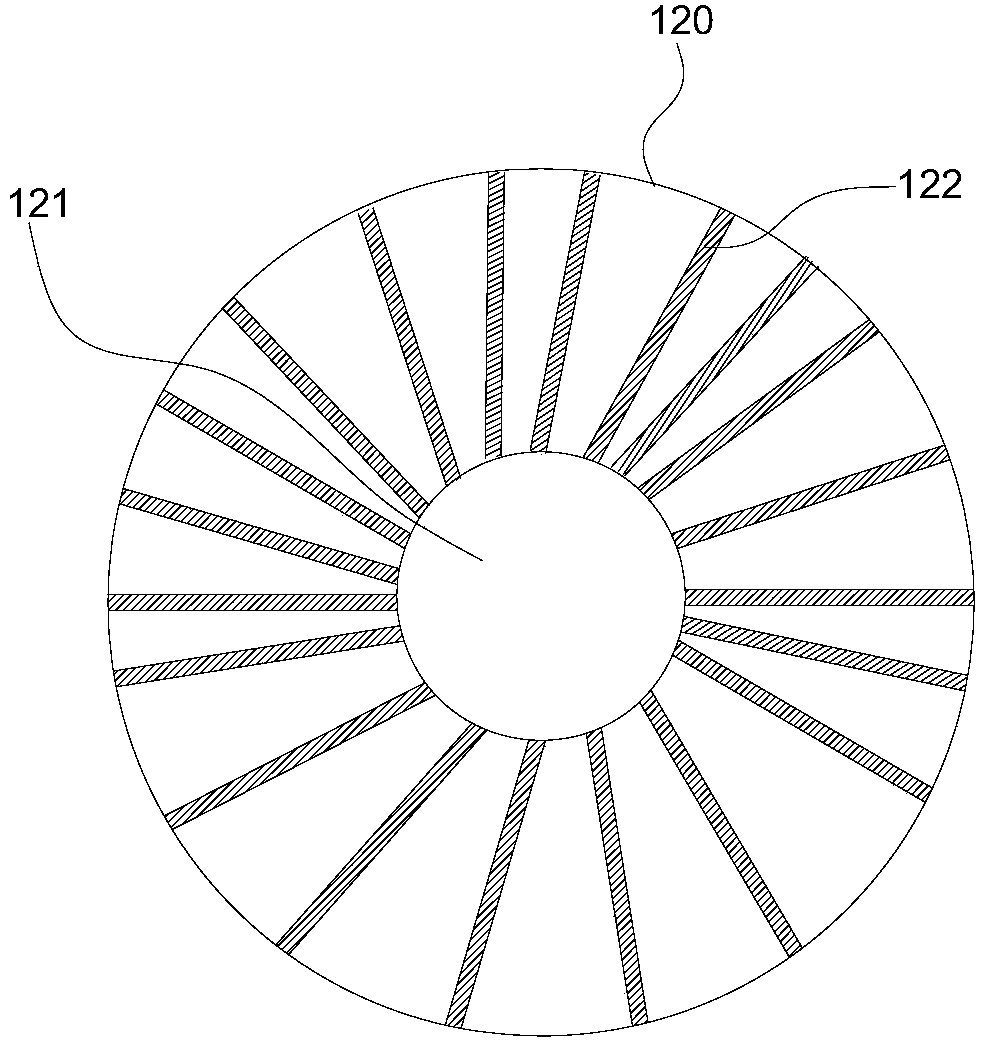

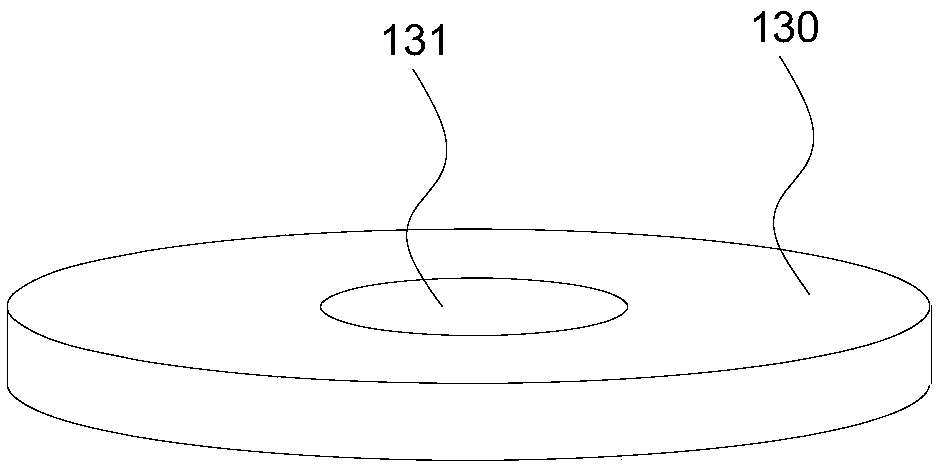

[0038] refer to Figure 1-4 , the pressure-balanced composite liner of this embodiment is ring-shaped, with a ring width of 9 ± 1 mm and an outer diameter of 35 mm, including a ring-shaped bearing cushion layer 110, a breathable cushion layer 120 and a top layer that are sequentially stacked and fixed together. Cushion 130. A first perforation 111 is formed in the middle of the bearing cushion 110 , a second perforation 121 is formed in the middle of the breathable cushion 120 , and a third perforation 131 is formed in the middle of the top cushion 130 . The breathable cushion 120 is provided with 20 grooves 122 from the second perforation 121 edge to the outer edge of the breathable cushion 120 (that is, the groove 122 runs through the annulus of the breathable cushion 120), and the length of the groove 122 is 8 -12mm, the groove width...

Embodiment 2

[0045] This embodiment provides a pressure-balanced composite gasket and a manufacturing method of the pressure-balanced composite gasket.

[0046] refer to Figure 7-8 , The pressure-balanced composite liner of this embodiment is ring-shaped, with a ring width of 14-15 mm and an outer diameter of 64 mm. A first perforation 211 is formed in the middle of the bearing cushion 210 , and a second perforation 221 is formed in the middle of the air-permeable cushion 220 . The breathable cushion 220 is provided with 20 grooves 222 from the second perforation 221 edge to the outer edge of the breathable cushion 220 (that is, the groove 222 runs through the annulus of the breathable cushion 220), and the length of the groove 222 is 14 -17mm, the groove width of the groove 222 is 60 μm, and the cross-sectional area of the groove 222 is about 2827 μm 2 . In this embodiment, the bearing cushion layer 210 is a foamed PE sheet with a thickness of 2 mm, and the breathable cushion layer ...

Embodiment 3

[0053] This embodiment provides a pressure-balanced composite gasket and a manufacturing method of the pressure-balanced composite gasket.

[0054] The pressure-balanced composite liner in this embodiment is ring-shaped, with a ring width of 8-10 mm and an outer diameter of 35 mm, and includes a ring-shaped bearing cushion layer and a breathable cushion layer that are sequentially stacked and fixedly bonded together. The middle part of the bearing pad is provided with a first perforation, and the middle part of the air-permeable pad is provided with a second perforation. The breathable cushion is provided with 20 grooves from the second perforated edge to the outer edge of the breathable cushion (that is, the groove runs through the annulus of the breathable cushion), and the length of the groove is 8-12mm. The width is 10 μm, and the cross-sectional area of the groove is about 78.5 μm 2 . In this embodiment, the bearing cushion layer is a foamed PE sheet with a thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com