FRP composite material floating raft vibration isolation device and its processing method

A technology of composite materials and FRP profiles, which is applied in the direction of propulsion engine, transportation and packaging, vibration suppression adjustment, etc. It can solve the problems of composite material main frame, weak impact resistance and limitation of joints, etc., and achieve compact structure and easy operation. Convenience and excellent shock absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

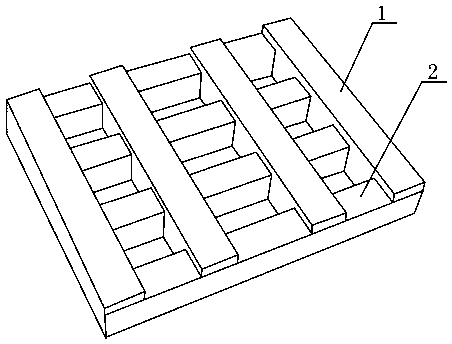

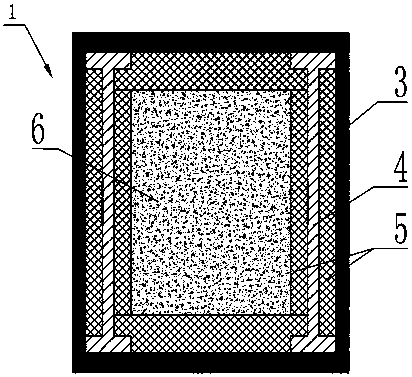

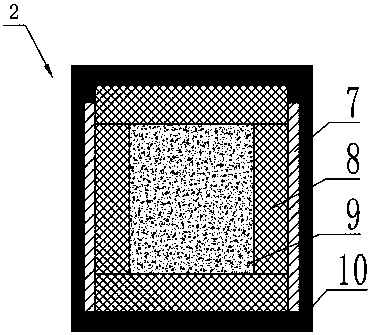

[0029] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the fiberglass composite material floating raft vibration isolation device of this embodiment includes a beam 1 and a longitudinal girder 2, and the beam 1 and the longitudinal girder 2 are combined into a cross box beam structure. Layer 3, the two ends of the inner wall of the first FRP outer layer 3 are respectively installed with I-shaped FRP profiles 4, the two I-shaped FRP profiles 4 are installed on both sides of the web and the upper and lower sides of the first FRP outer layer 3. The first resin concrete block 5, the first resin concrete block 5 is surrounded by a quadrilateral structure, and the first polyurethane foam 6 is located inside the first resin concrete block 5; The inner two ends of the second FRP outer layer 10 are respectively equipped with FRP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com