Reinforced concrete combined double-layer hazardous rock falling protection hangar tunnel

A technology of dangerous rock falling and protective shed, applied in the field of sheds and caves, can solve the problems of large foundation volume, increased structural risk, and poor economic efficiency, and achieve the effects of strong impact resistance, good structural economy, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

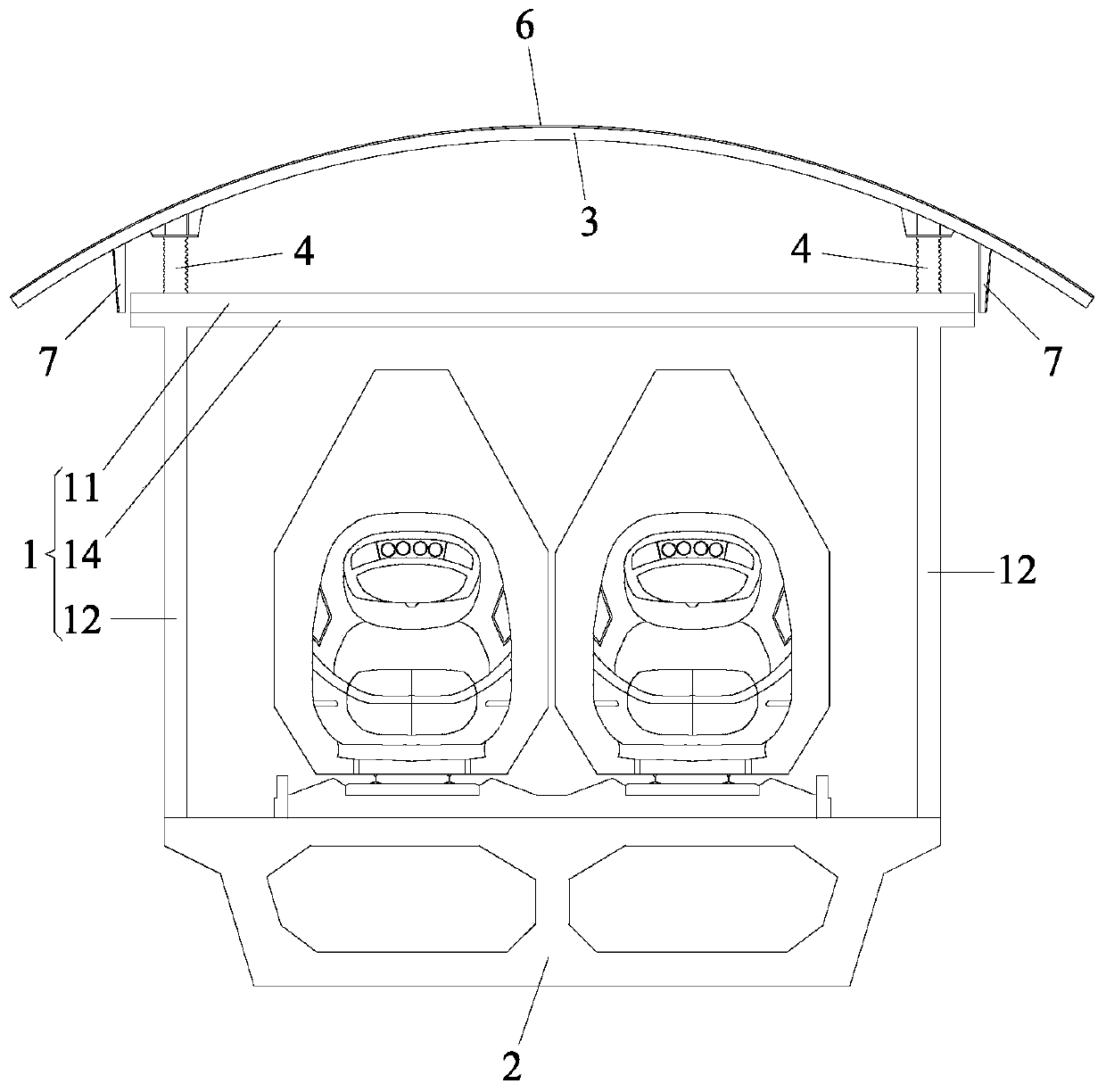

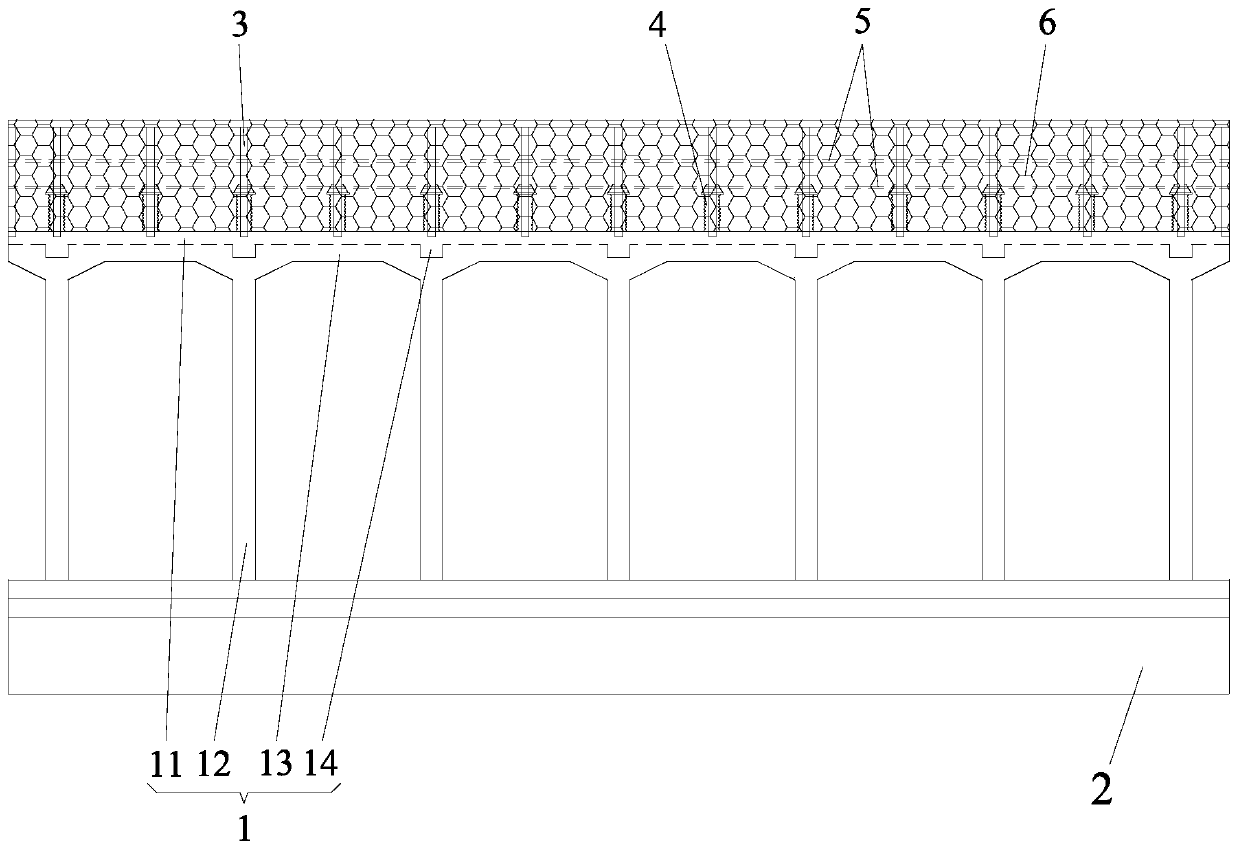

[0034] Such as Figure 1-3 As shown, a steel-concrete combined double-layer dangerous rockfall protection shed tunnel according to the present invention is used for the protection of dangerous rockfall rockfall protection for high pier bridges in mountainous areas, and includes a reinforced concrete shed cave body 1, which is connected to the bridge on the main beam 2.

[0035] The shed cave body 1 includes a top plate 11, a column 12, a longitudinal beam 13 and a crossbeam 14, two columns 12 are arranged laterally along the bridge, and several columns 12 are arranged at intervals along the longitudinal direction of the bridge, and two vertical columns are adjacent to each other vertically. The tops of the columns 12 are connected by a longitudinal beam 13, and the tops of two adjacent columns 12 are connected by a beam 14. The shed hole body 1 forms a frame structure, and the columns 12 The top is connected to the top plate 11 .

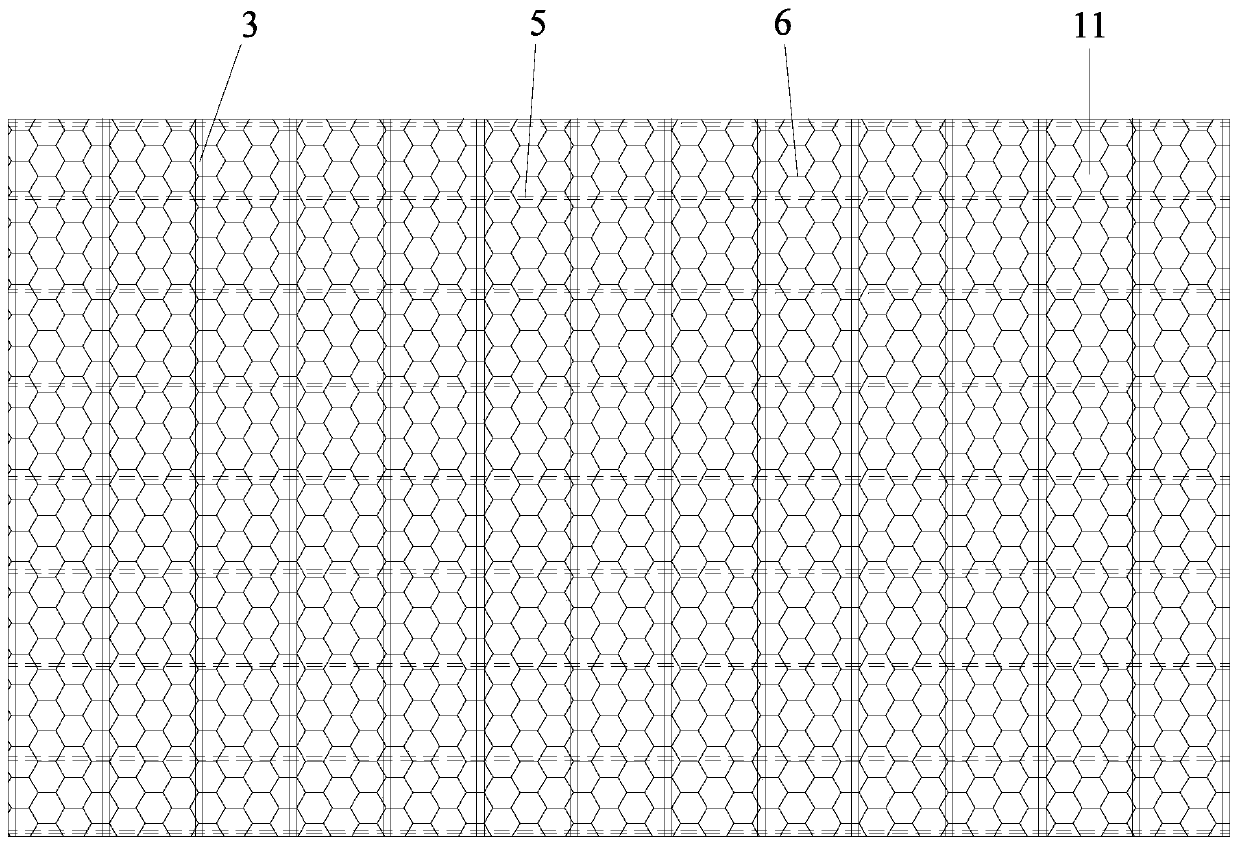

[0036] The roof 11 is provided with several...

Embodiment 2

[0041] Such as Figure 4 As shown, a steel-concrete combination double-layer dangerous rockfall protection shed of the present invention is used for the protection of dangerous rockfalls on high-pier bridges in mountainous areas. The difference from Example 1 is that in this embodiment, the The main girder 2 adopts a single-chamber box girder. The box girder is prefabricated and transported, and the flange plate part is post-cast construction. At the same time, the flange plate is provided with a reinforcing beam, and the column 12 is connected to the reinforcing beam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com