Plate conveyer

A conveyor, plate type technology, applied in the direction of conveyor, transportation and packaging, surface pretreatment, etc., can solve the problem of increasing power source, and achieve the effect of reducing power source and improving automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

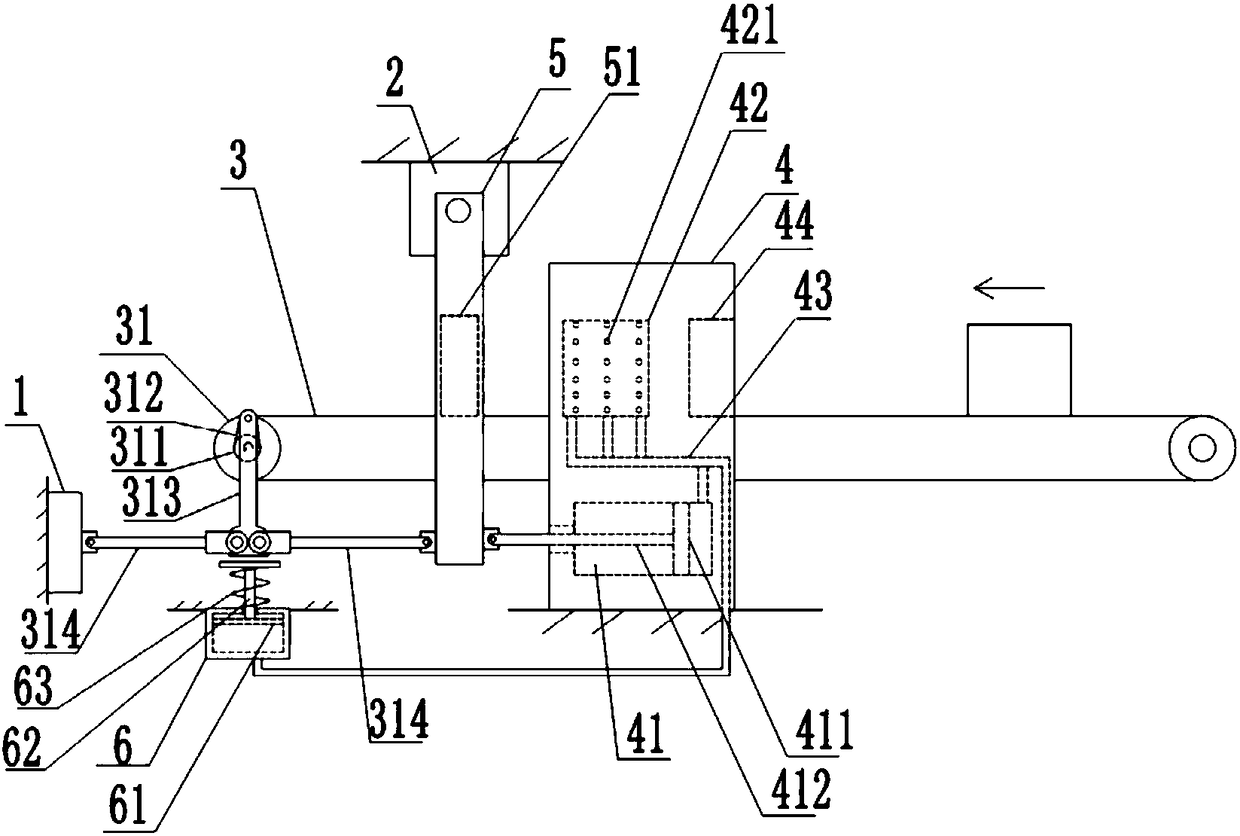

[0031] Embodiment one is basically as attached figure 1 , figure 2 with image 3 Shown:

[0032] A plate conveyor, see figure 1 , including a fixed seat 1, a fixed platform 2, a conveyor body 3 and a transmission roller 31 for driving the movement of the conveyor body 3, and there are two transmission rollers, which are respectively located at the two ends of the conveyor body 3; and the conveyor body 3 The conveying roller 31 on the left side is fixed with the output end of motor. Both the fixed seat 1 and the fixed platform 2 are fixed on the wall or the ground, and the fixed platform 2 is located above the conveyor body 3 , and the fixed seat 1 is close to the output end of the conveyor body 3 .

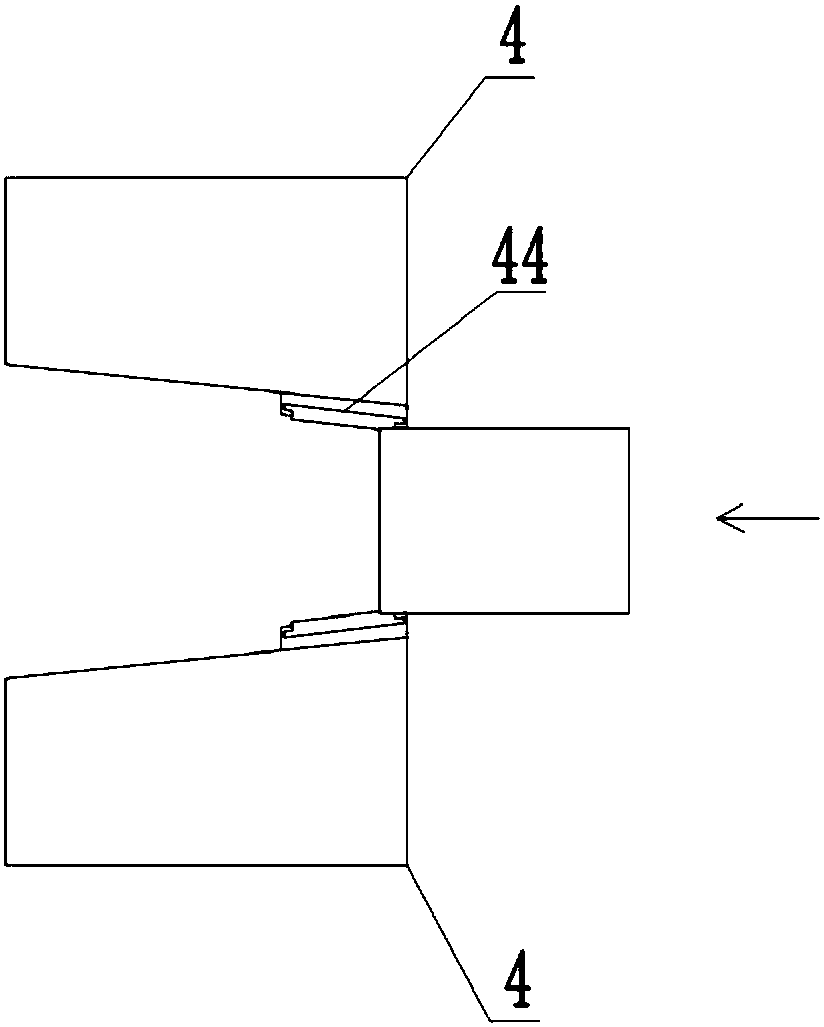

[0033] Both sides of the conveyor are provided with a drying section 4 and a swinging plate 5, and the drying section 4 and the swinging plate 5 are arranged in sequence along the conveying direction of the conveyor body 3; the drying section 4 is fixed on the ground. The up...

Embodiment 2

[0044] The difference between this embodiment and the first embodiment is that the swing plate 5 is provided with an oil cavity, and anti-rust oil is provided in the oil cavity. The upper end of the swing plate 5 is provided with an oil inlet connected to the oil chamber, and the oil inlet is provided with a plug for blocking the oil inlet; when in use, the plug can be inserted into the oil inlet. The oil cavity is provided with a through hole, and the oil-coated layer 51 is fixed with a cotton thread, and the end of the cotton thread extends into the anti-rust oil; Oil the metal surfaces on both sides of the objects in between.

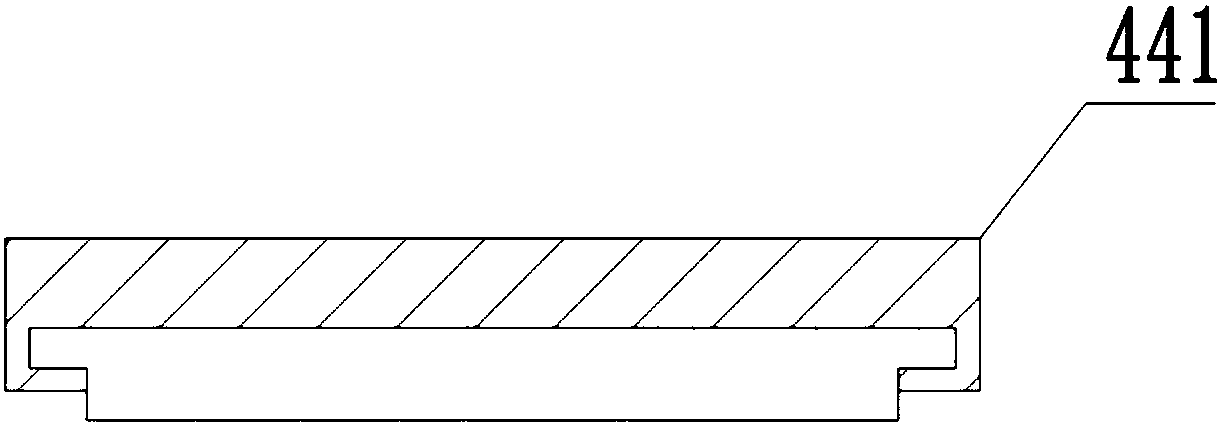

[0045] Such as Figure 4 , the detachable connection between the clamping plate 441 and the inclined surface; specifically: both sides of the clamping plate 441 are fixed with protrusions 4411, and the inclined surface is fixed with a clamping track 45 for clamping into the protrusions 4411; it is convenient to remove the clamping plate 441 from dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com