Method for preparing porous carbon from scallions and waste

A porous carbon and waste technology, which is applied in the field of porous carbon electrode materials for supercapacitors and its preparation, can solve the problems of poor activation effect of activators, small specific surface area of activated carbon materials, difficulty in adjusting the pore structure and specific surface area of activated carbon, and achieve broaden The effect of added value in the industrial chain, high medicinal value, and excellent pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

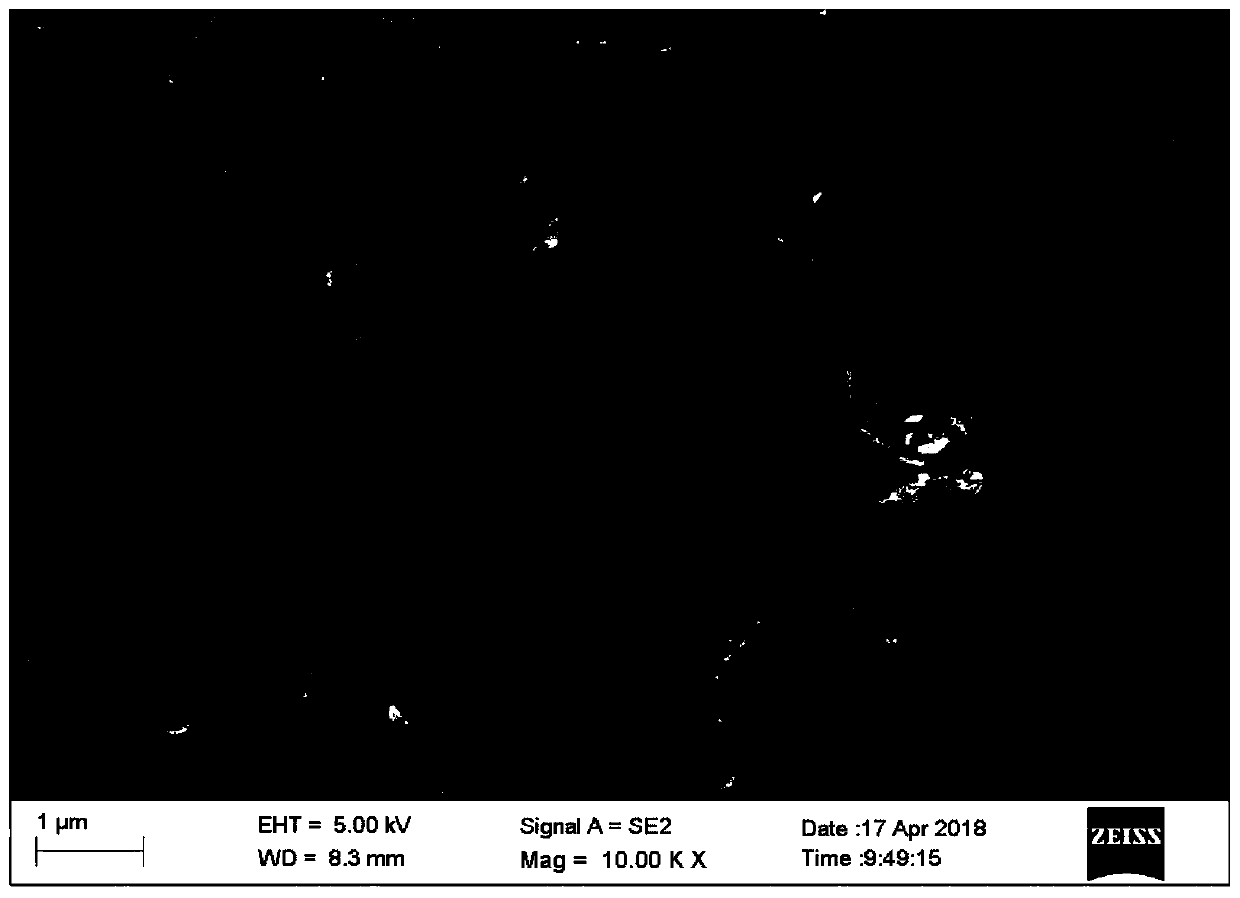

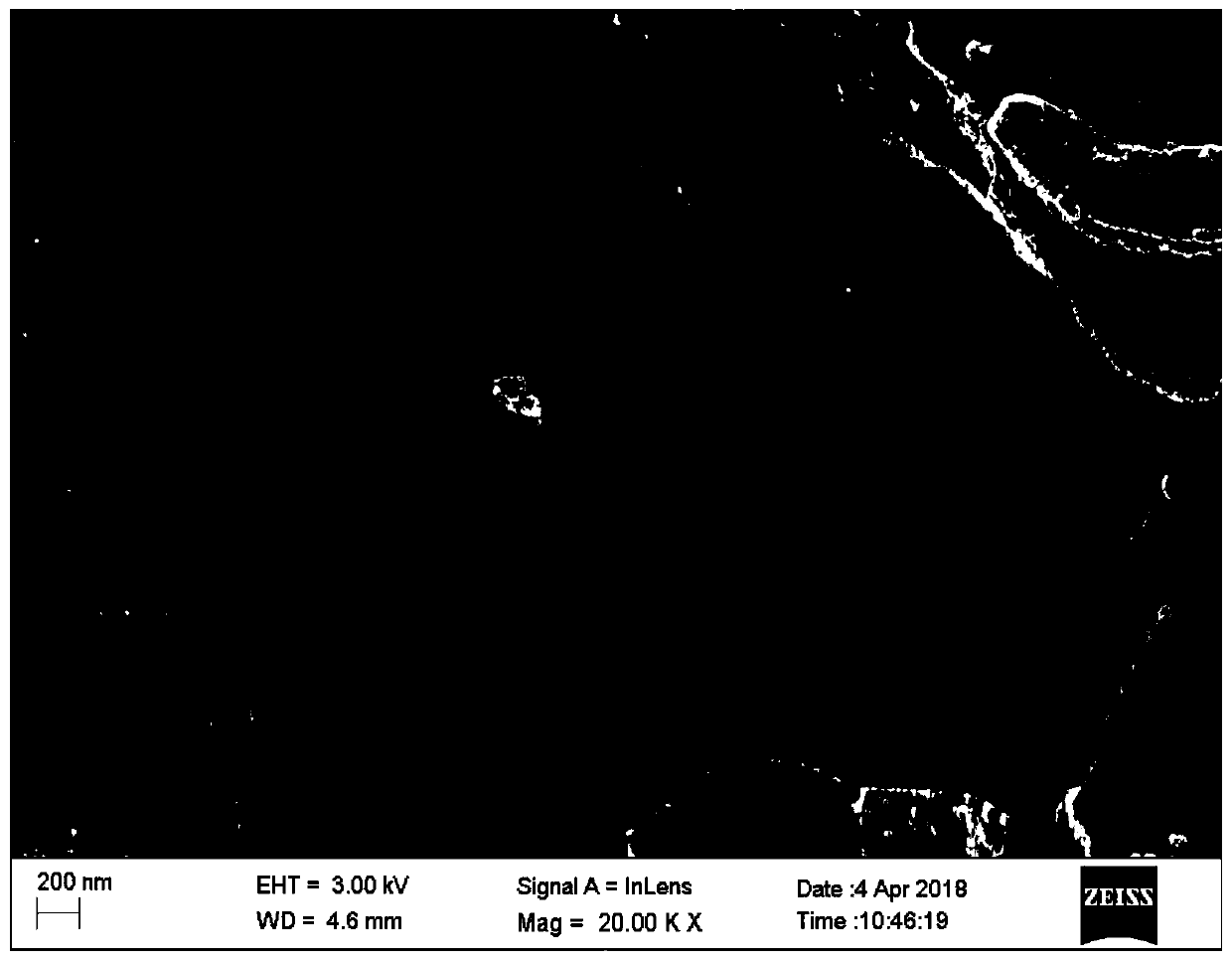

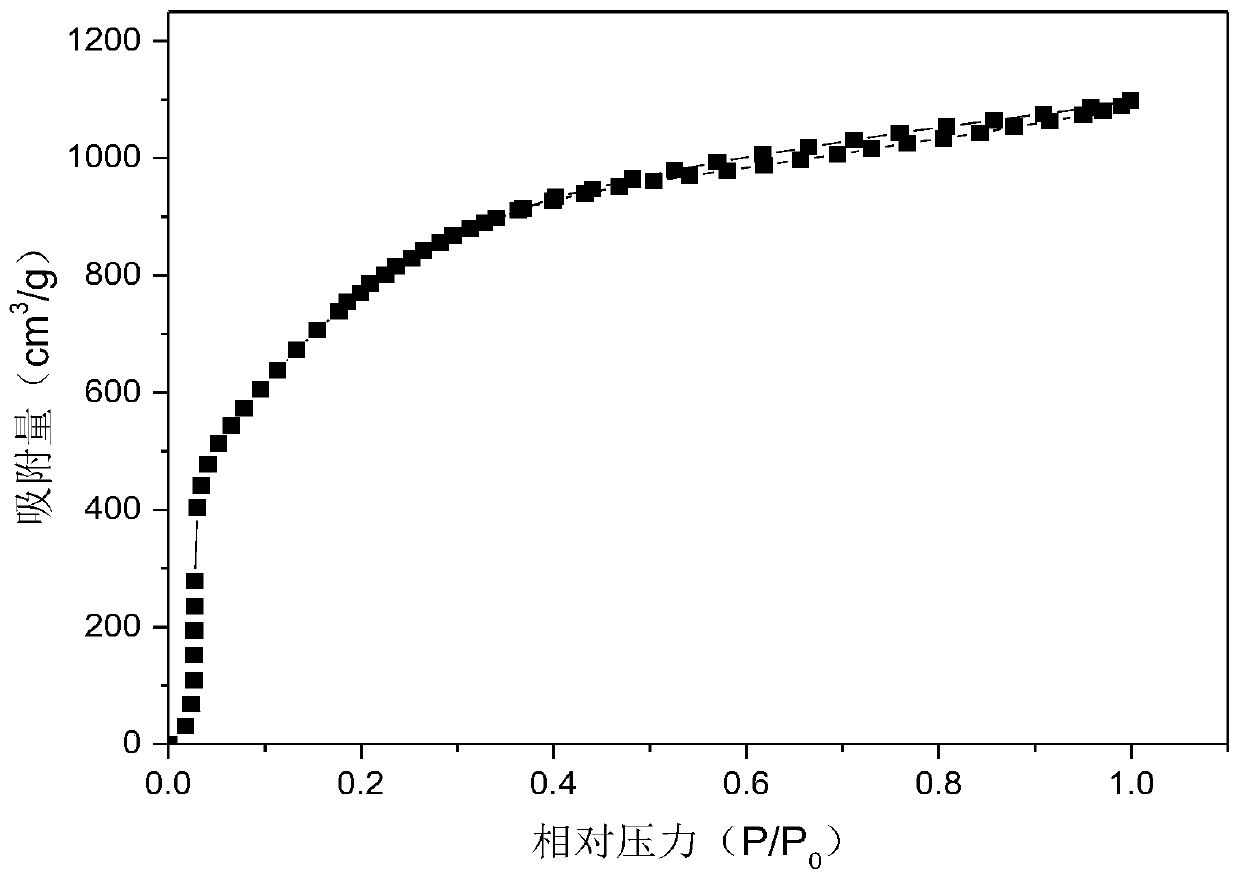

Image

Examples

Embodiment 1

[0067] A method for preparing porous carbon from scallions and wastes thereof, comprising the steps of:

[0068] Step 1: chop and wash the green onions, place them in an ethanol solution with a mass concentration of 80% according to the ratio of material to liquid 1g: 10ml, heat in a water bath at 80°C for 8 hours, dry and pulverize;

[0069] In step 2, the sample powder obtained in step 1 was placed in a tubular resistance furnace, heated to 600 °C in a nitrogen atmosphere (flow rate: 1.5 L / min), the heating rate was 5 °C / min, kept for 2 hours, cooled to room temperature, and prepared Onion carbonized material;

[0070] Step 3: pickling the green onion carbonized material obtained in Step 2 with 3M hydrochloric acid solution at 80°C, then washing with 80°C deionized water until neutral, and drying for later use;

[0071] Step 4, weigh 4g of the product obtained in step 3, weigh 16g of KOH solid according to the carbon-to-alkaline ratio of 1:4 and configure it into a saturate...

Embodiment 2

[0075] A method for preparing porous carbon from scallions and their wastes is the same as in Example 1, except that the carbon-to-alkali ratio is 1:3.

Embodiment 3

[0077] A method for preparing porous carbon from scallions and their wastes is the same as in Example 1, except that in step 1, only the scallions need to be washed, dried and crushed, and no water-bath heating pretreatment is required.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com