An environment-friendly biogas digester for fermentation of organic matter

An organic matter and biogas digester technology, applied in the field of biogas digesters, can solve the problems of increasing the floor space and hidden dangers of safety, increasing the pressure in the pool, and accumulating a large amount of biogas, so as to improve the effective utilization rate, avoid pollution and improve the safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

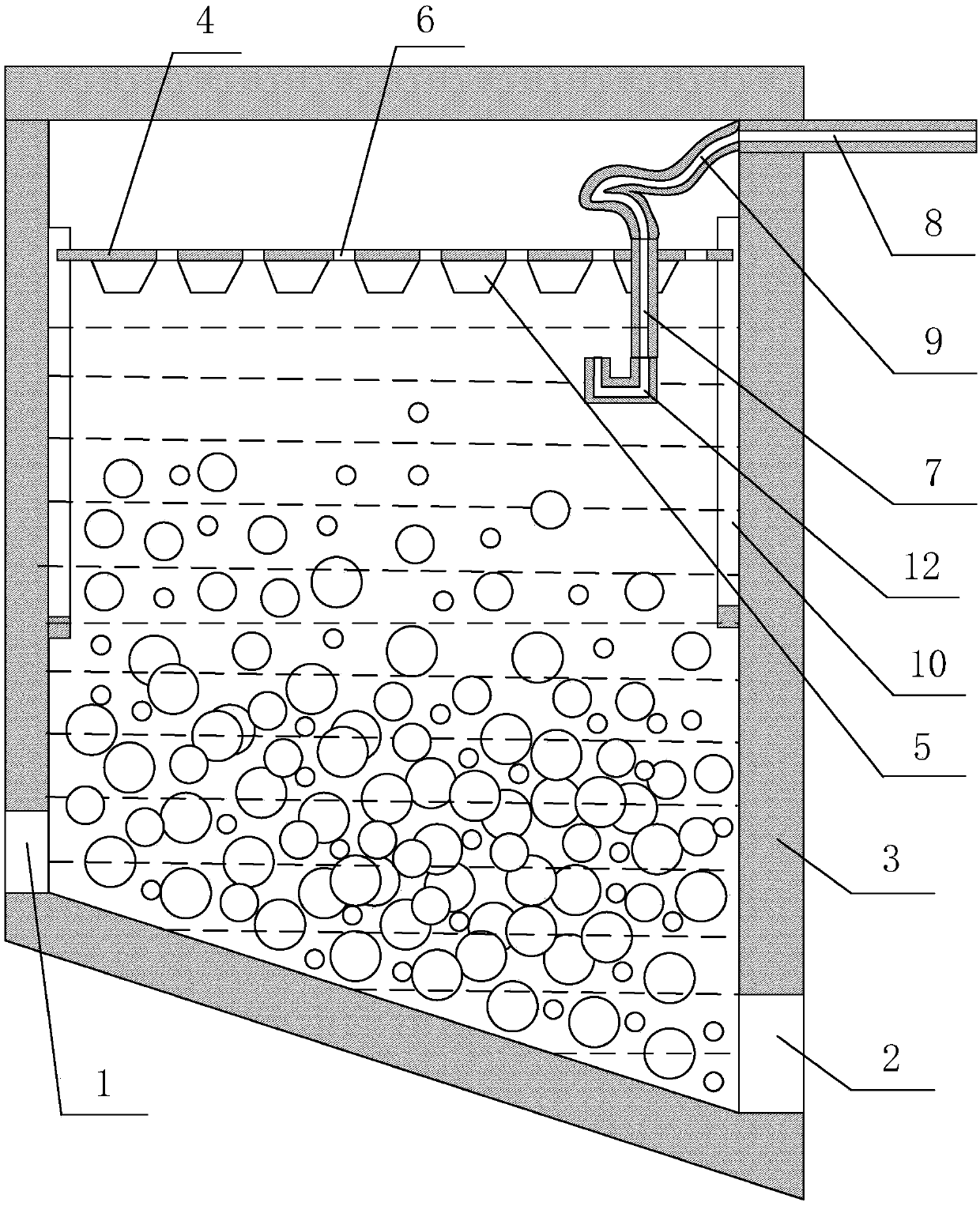

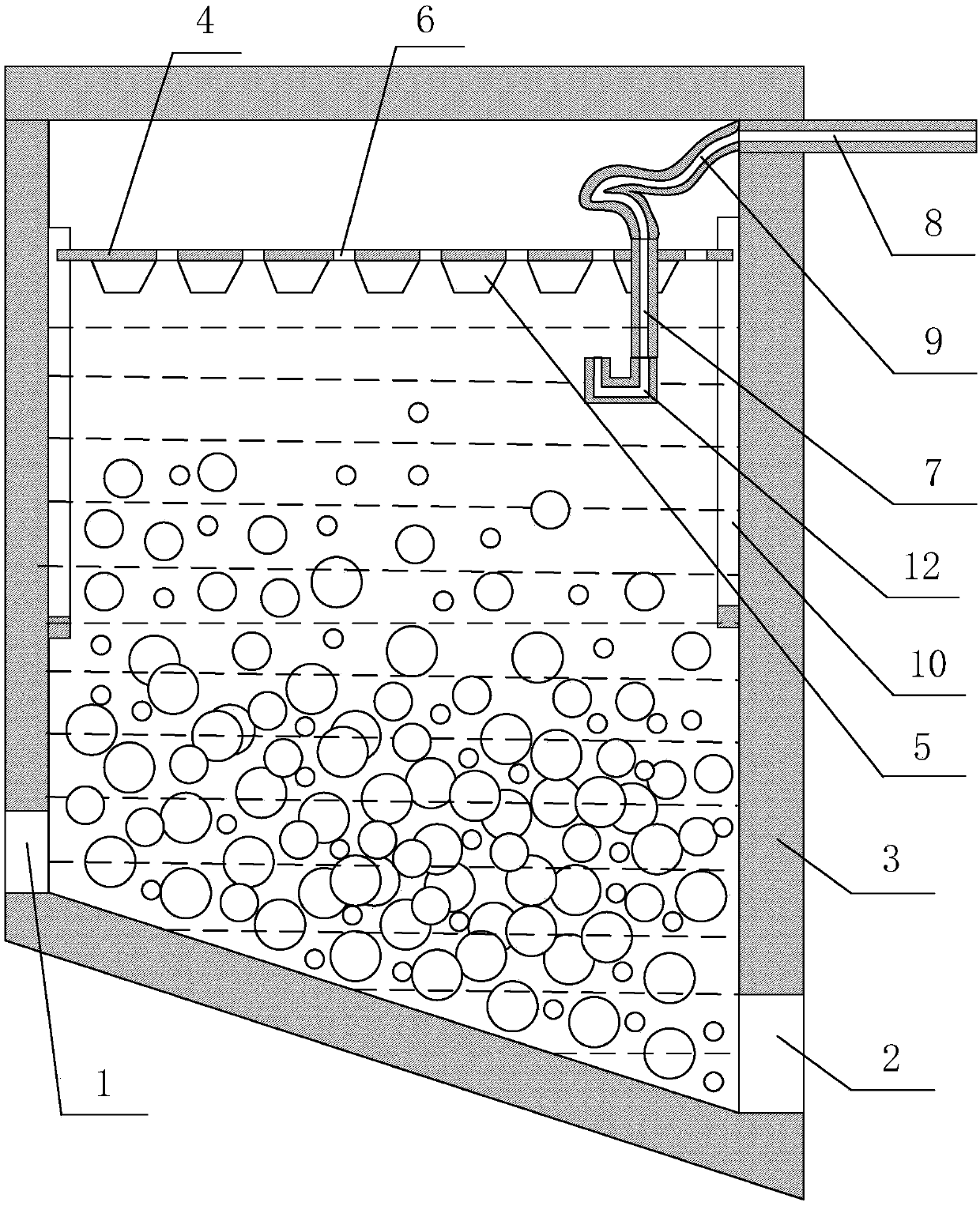

[0030] An environment-friendly biogas digester for fermentation of organic matter, such as figure 1 As shown, it includes a biogas digester body 3 having a feed port 1 and a discharge port 2, and a liquid drainage device is installed in the biogas digester body 3.

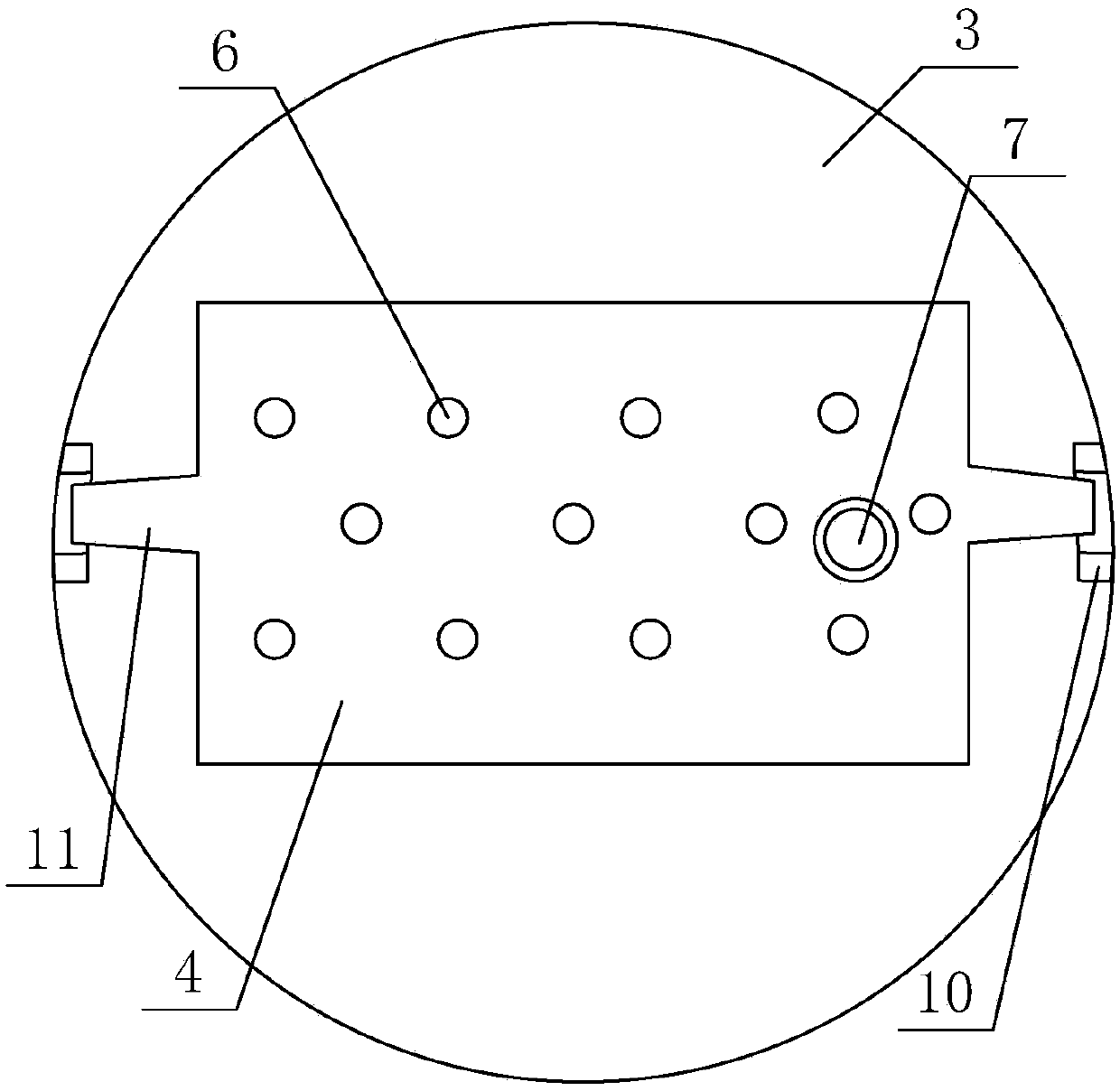

[0031] Wherein, the liquid drainage device includes a floating plate 4 placed on the surface of the biogas slurry in the biogas tank body 3, a plurality of floats 5 fixed under the floating plate 4, and vent holes 6 on the floating plate 4 between the floats 5, through which The floating plate 4 and the liquid discharge inner pipe 7 extending into the biogas slurry, the liquid discharge outer pipe 8 that runs through the biogas tank body 3 and is located at the top of the biogas tank body 3, and one end is connected to the top of the liquid discharge inner pipe 7, The connecting hose 9 that the other end communicates with the liquid discharge outer pipe 8, such as figure 1 and figure 2 shown.

[0032] In the pr...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is that in this embodiment, the structure and material of the floating plate 4, the float 5 and the connecting hose 9 are further optimized, and the specific settings are as follows:

[0036] The float 5 is a conical structure with a large top and a small bottom. The floating plate 4 is made of a hard plastic plate, the float 5 is made of foamed plastic, and the floating plate 4 floats on the biogas slurry surface through the action of the float 5 . The connecting hose 9 is a stainless steel metal hose, and the length of the connecting hose 9 is the same as the height of the U-shaped stopper 10 .

Embodiment 3

[0038] The difference between this embodiment and Embodiment 1 is that the structure and settings inside the biogas digester body 3 are further optimized in this embodiment, and the specific settings are as follows:

[0039] The bottom end of the biogas digester body 3 is arranged on an inclined plane, and the liquid discharge inner pipe 7 is located above the bottom end of the inclined plane. The inner wall of the biogas digester body 3 is also equipped with a U-shaped stopper 10, and the floating plate 4 is also provided with a stopper tooth 11 extending into the U-shaped groove of the U-shaped stopper 10. There are two U-shaped stoppers 10, which are respectively arranged on opposite sides of the biogas digester body 3, as shown in Fig. 1 and figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com