Control method, device and system for air blower of polycrystalline silicon chilling room

A technology for polycrystalline silicon ingots and cooling fans, which is applied in the field of silicon wafer manufacturing, can solve problems such as wasting electric energy, and achieve the effects of saving electric energy, improving control accuracy, and simplifying control methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

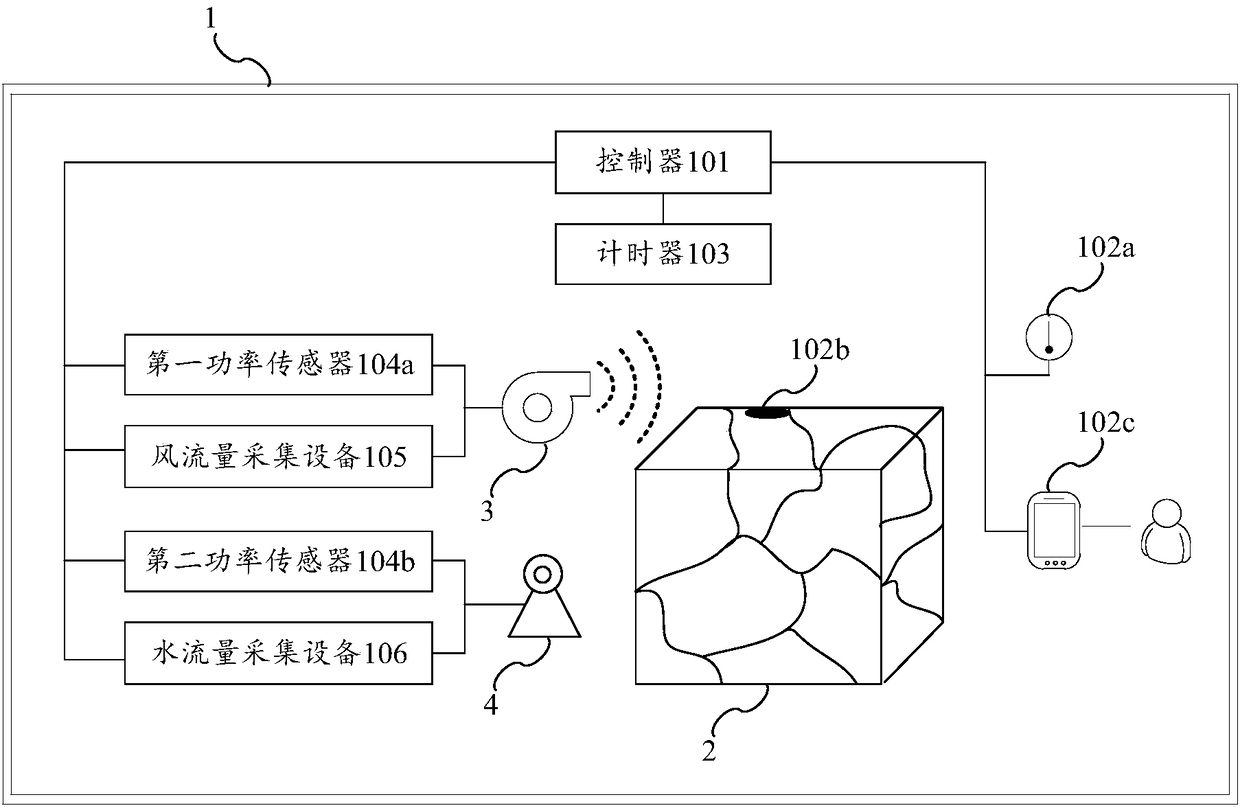

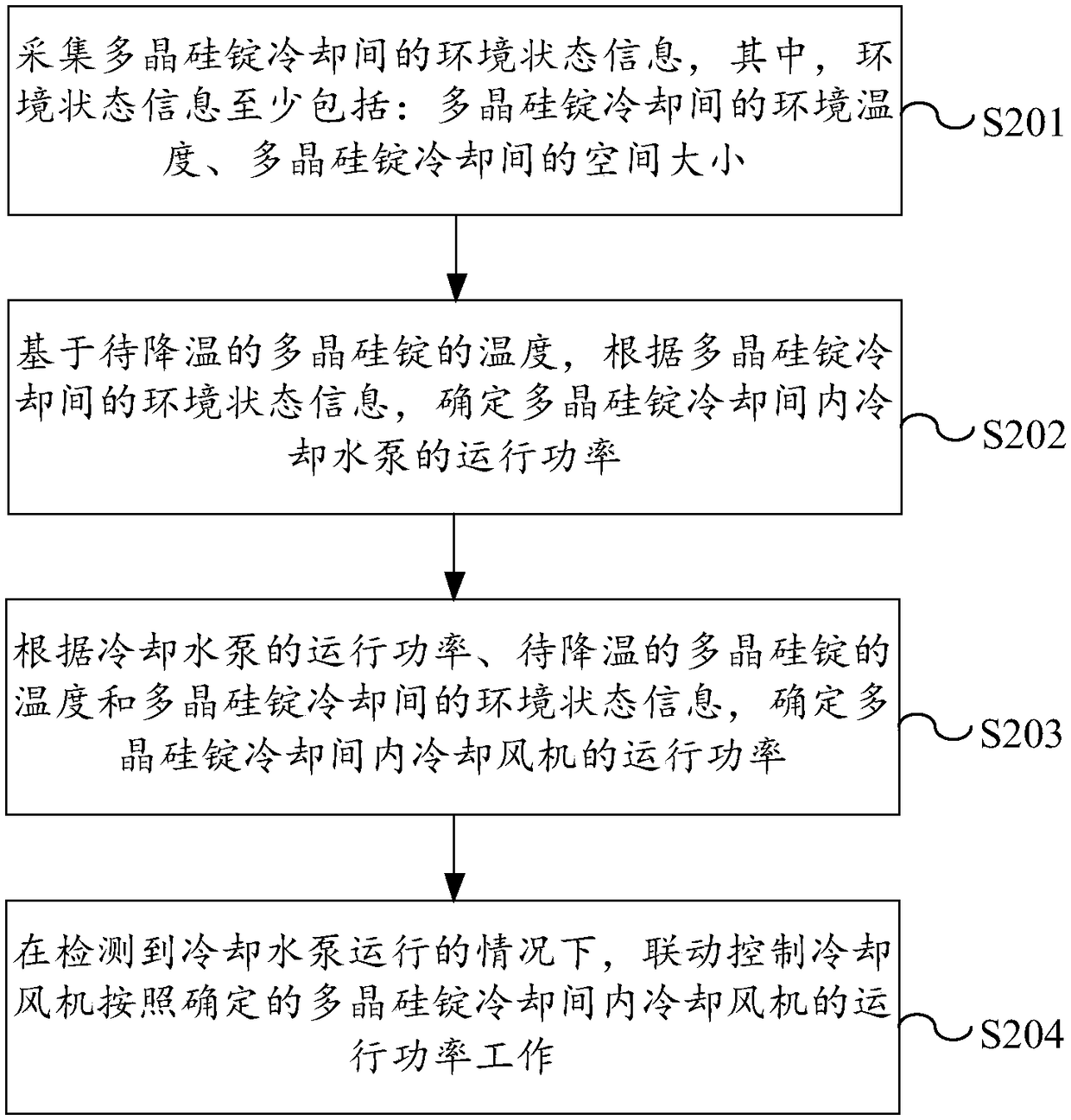

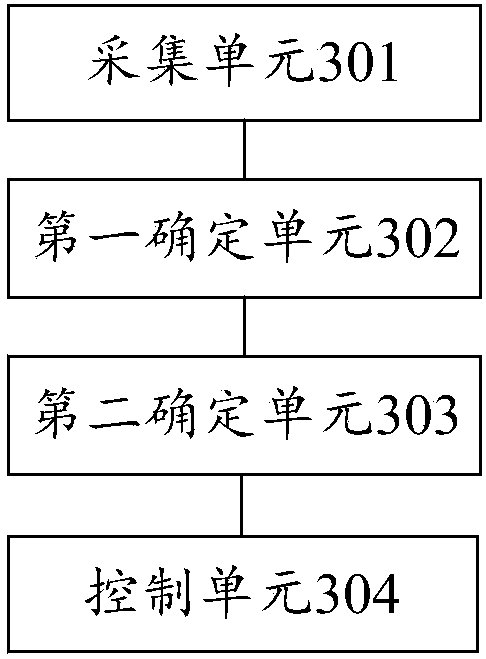

[0023] In order to explain the overall concept of the present application more clearly, the following detailed description will be given by way of examples in combination with the accompanying drawings.

[0024] The embodiment of the present application discloses a control system for a fan in a polycrystalline silicon ingot cooling room, which can be used to control the fan speed in the polycrystalline silicon ingot cooling process. In the cooling process of polycrystalline silicon ingots, fans are needed to reduce the temperature of cooling water. At present, in the existing polysilicon ingot cooling process, the fan is always running regardless of whether the ambient temperature needs to be turned on. If the fan is always on, it will not only waste electric energy, but also cause the cooling water temperature to be too low and affect The qualified rate of polysilicon ingots.

[0025] Therefore, in order to achieve low power consumption and high pass rate production, the fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com