Unbleach pulp and preparation technology and application thereof

A preparation process, a technology for uncolored pulp, applied in multi-stage pulping process, pulp beating/refining method, textiles and papermaking, etc. The pulping effect is remarkable, the heating cost is saved, and the pulp yield is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

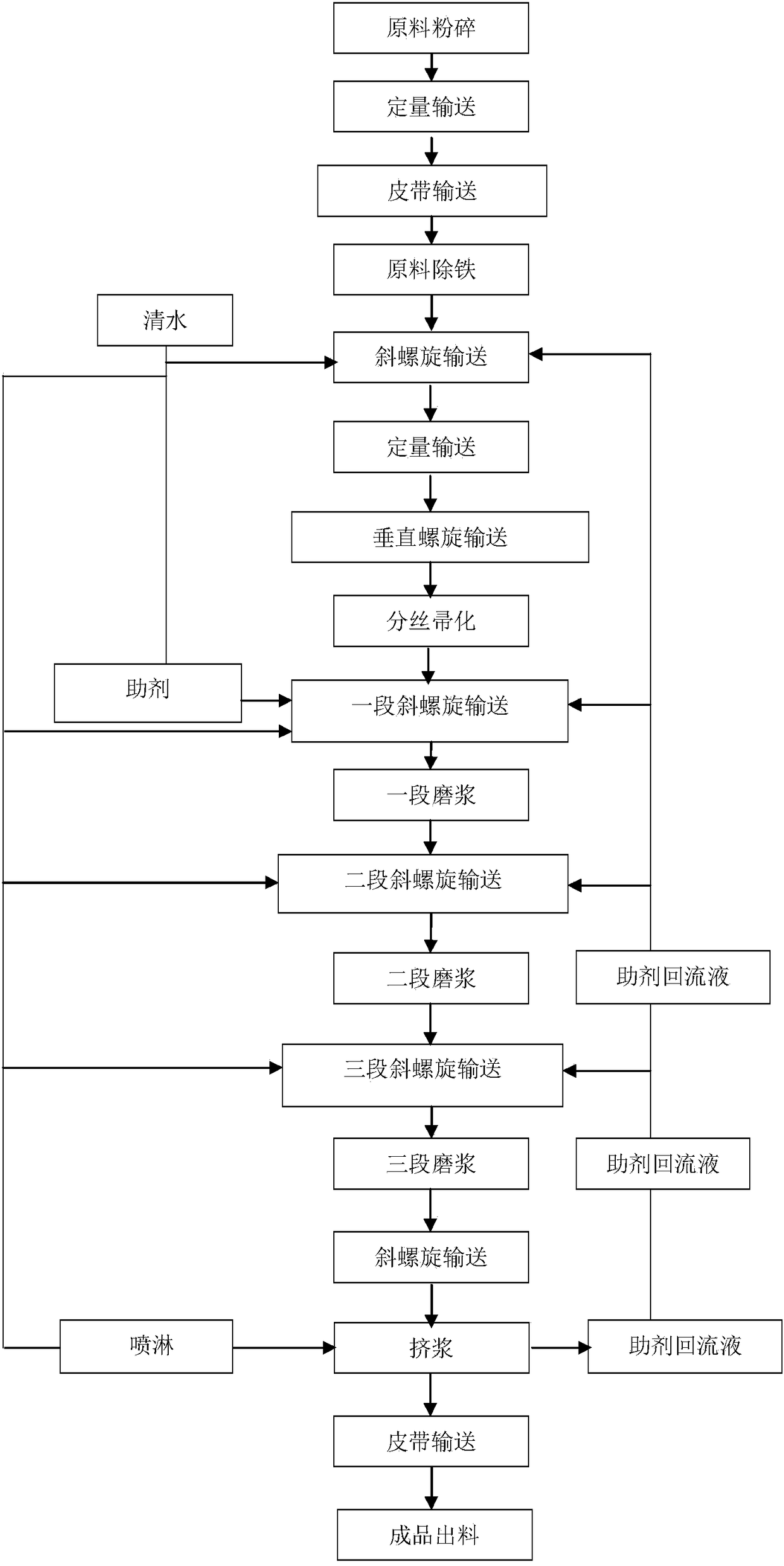

Method used

Image

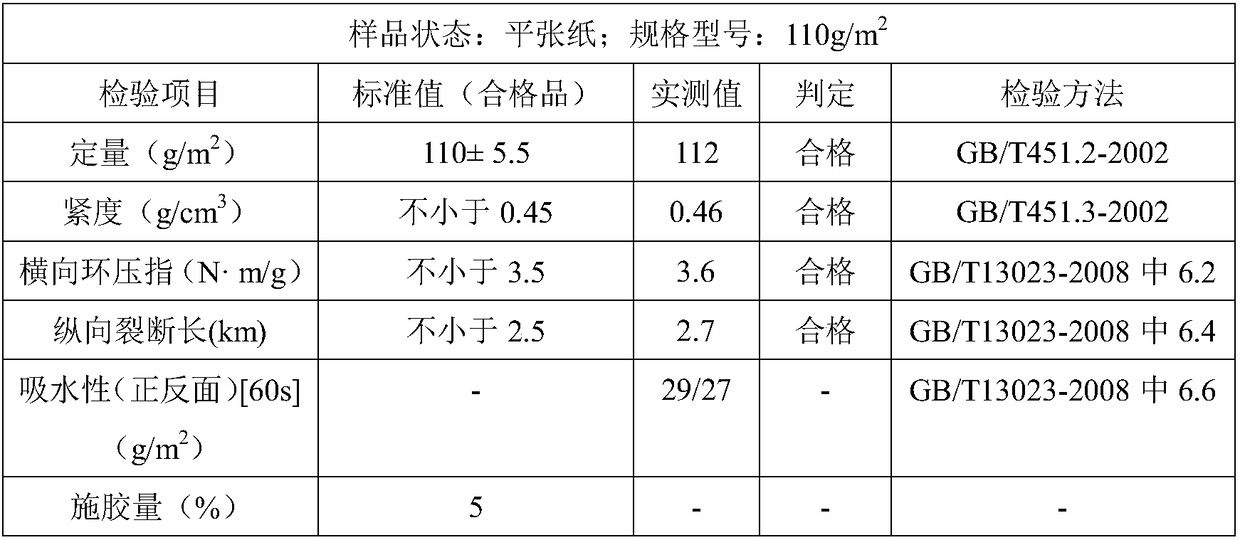

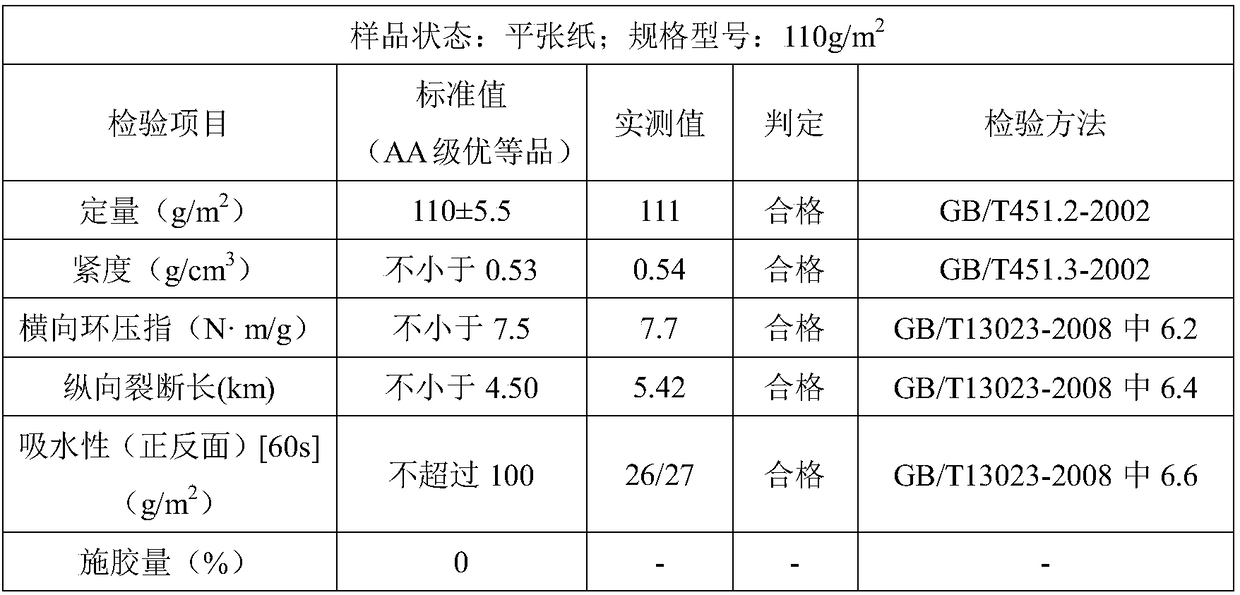

Examples

Embodiment 1

[0081] Example 1 A natural color paste and its pulping process

[0082] A kind of natural color paste, made of wheat straw, the production scale is 10,000 tons of slurry per year, the beating degree of the obtained natural color paste is 55-70 ° SR beating, the preparation process is as follows:

[0083] (1) Raw material crushing: the wheat straw is preliminarily crushed at a rate of 3 t / h, and the length after the primary crushing is 2 cm.

[0084] (2) Iron removal treatment: the pulverized raw material in step (1) is subjected to iron removal treatment;

[0085] The iron removal treatment is two-stage. The crushed raw materials are firstly subjected to one-stage iron removal to remove iron-containing impurities close to the surface of the belt in the raw materials, and then undergo a second-stage iron removal to remove iron-containing impurities inside the raw materials; iron removal treatment steps and raw materials The raw material processing rate ratio for the pulverizat...

Embodiment 2

[0093] Example 2 A natural color paste and its pulping process

[0094] A kind of natural color paste, made of straw, the production scale is 10,000 tons of slurry per year, the beating degree of the obtained natural color paste is 55-70 ° SR beating, the preparation process is as follows:

[0095] (1) Raw material crushing: Preliminarily crush the rice straw at a crushing rate of 2t / h, and the length of the primary crushed rice straw is 1cm.

[0096] (2) Iron removal treatment: the pulverized raw material in step (1) is subjected to iron removal treatment;

[0097] The iron removal treatment is two-stage. The crushed raw materials are firstly subjected to one-stage iron removal to remove iron-containing impurities close to the surface of the belt in the raw materials, and then undergo a second-stage iron removal to remove iron-containing impurities inside the raw materials; iron removal treatment steps and raw materials The raw material processing rate ratio for the crushing...

Embodiment 3

[0105] Example 3 A natural color paste and its pulping process

[0106] A kind of natural color paste, made of waste wood chips, with a production scale of 10,000 tons of slurry per year, the beating degree of the obtained natural color paste is 60 ° SR beating, and the preparation process is as follows:

[0107] (1) Raw material crushing: Preliminary crushing of waste wood chips, the crushing rate is 4t / h, and the length after primary crushing is 3cm.

[0108] (2) Iron removal treatment: the pulverized raw material in step (1) is subjected to iron removal treatment;

[0109] The iron removal treatment is two-stage. The crushed raw materials are firstly subjected to one-stage iron removal to remove iron-containing impurities close to the surface of the belt in the raw materials, and then undergo a second-stage iron removal to remove iron-containing impurities inside the raw materials; iron removal treatment steps and raw materials The raw material processing rate ratio for th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com