Open-air slope coal mining and transporting device and working face rapid transferring method thereof

A technology of transportation device and working face, applied in the field of mining machinery, can solve the problems of unbalanced mining time and transfer time, coal cannot be transported quickly and timely, and consume a lot of manpower and material resources. Coal sprinkling phenomenon and the effect of reducing coal sprinkling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following clearly and completely describes the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

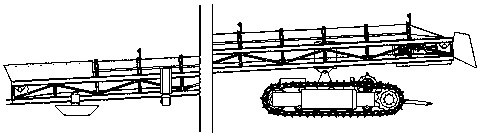

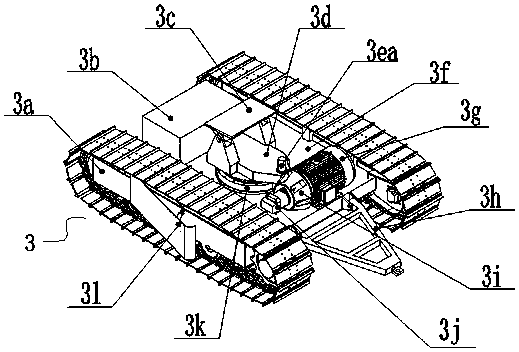

[0037] Such as Figure 1-6 As shown, a crawler belt continuous conveying device for open-pit side coal mining, including a skid steering system, a walking slewing system, a rotary disk locking device, a material conveying system, and a remote monitoring system;

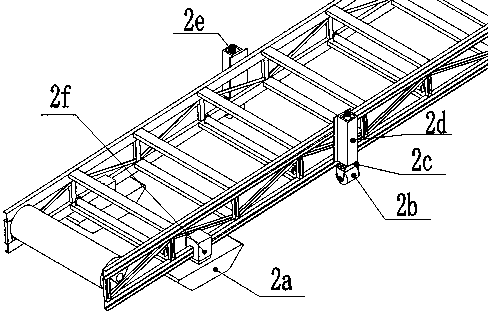

[0038] Such as figure 2 As shown in the skid steering system, the shoe guide cylinder 2f and the steering device sleeve 2d are welded on the main beam of the truss 1g, the telescopic rod 2c can be stretched and retracted along the sleeve 2d under the drive of the motor 2e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com