Bearing and sealing device

A sealing device and bearing sealing technology, which is applied to the sealing of bearing components, shafts and bearings, and engines, and can solve the problems of low roughness, strict requirements for dust rings, and high dimensional accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

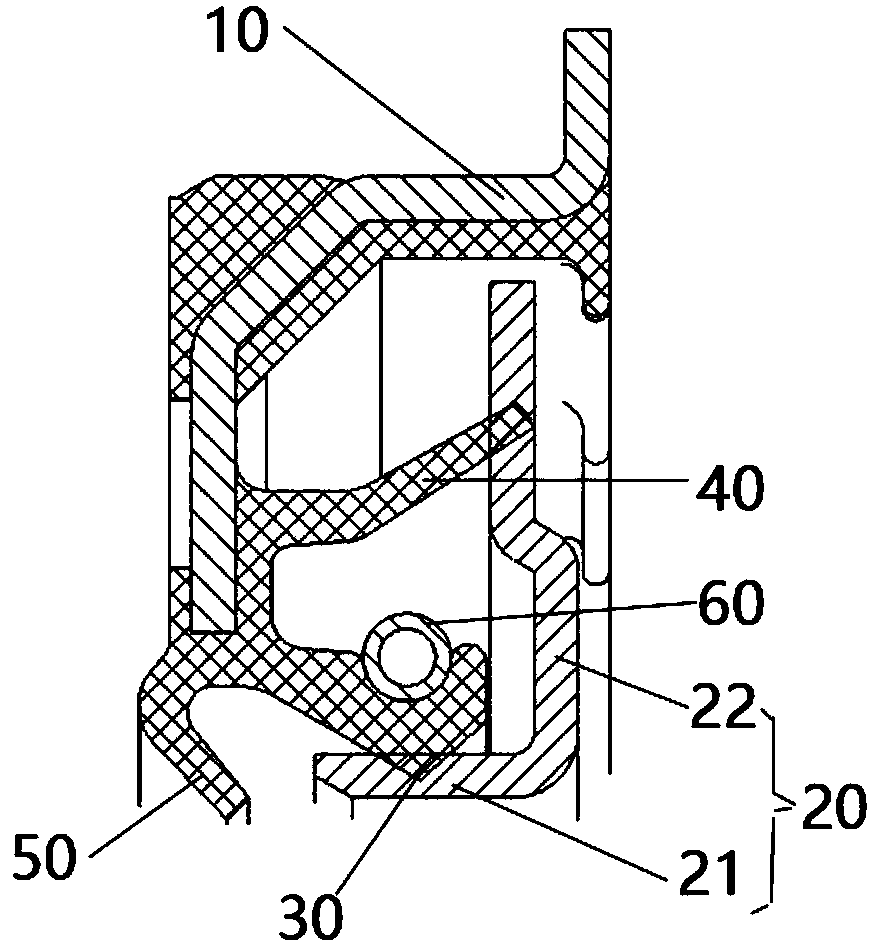

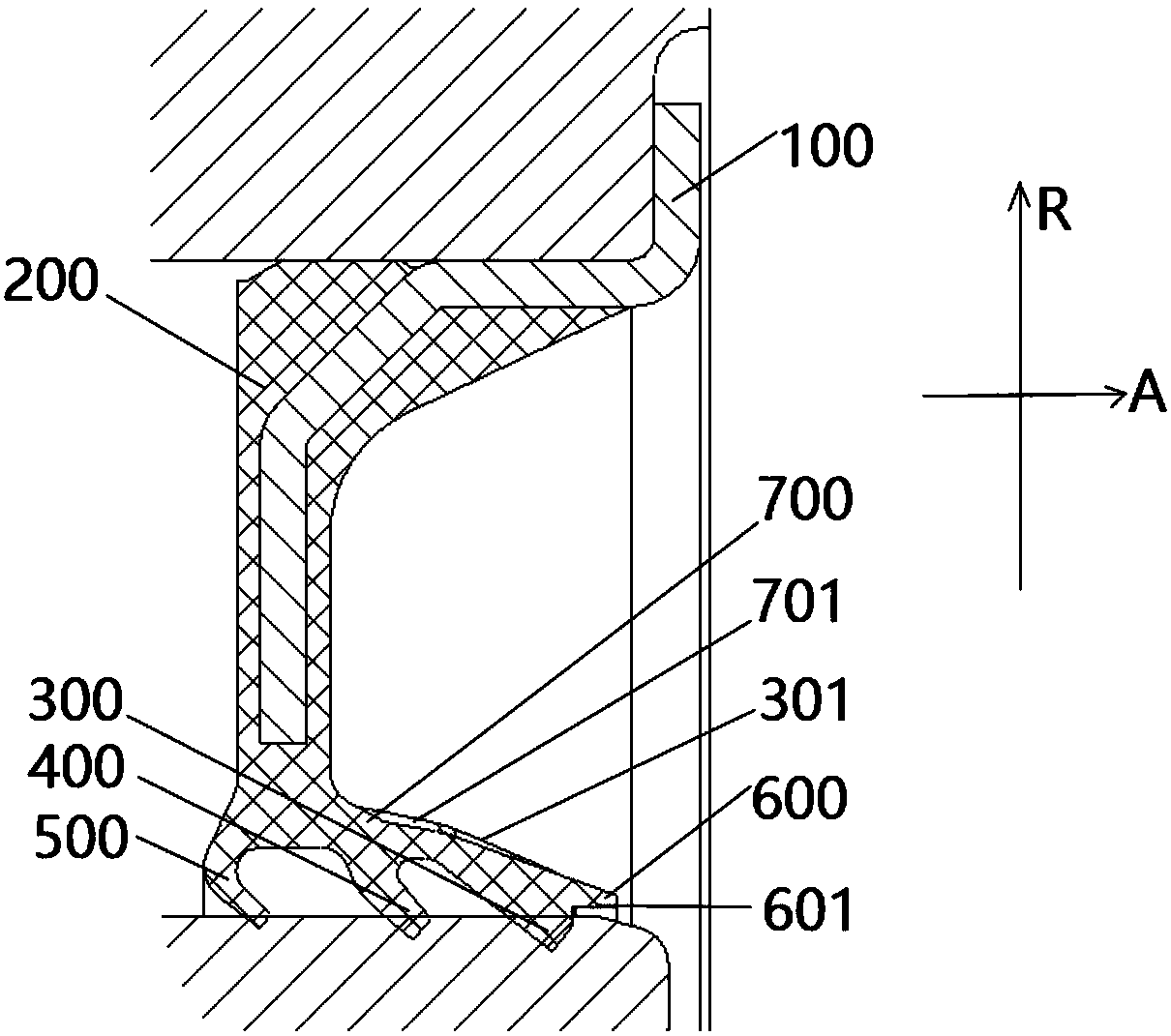

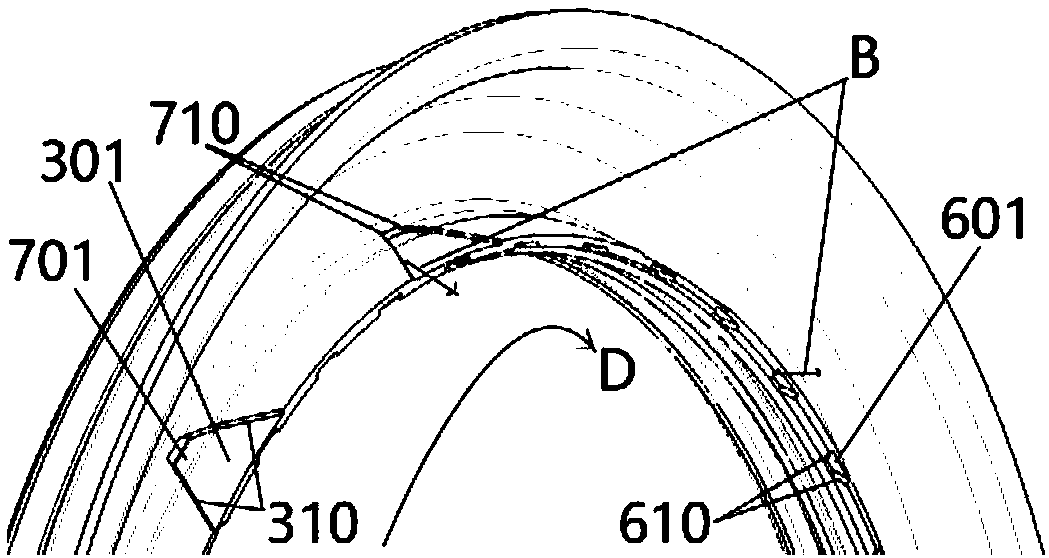

[0036] It can be seen from the background art that a bearing sealing device with a dust-proof ring has good sealing performance. However, the sealing device has strict requirements on the dust-proof ring, which must be made of corrosion-resistant metal materials. During the operation of the bearing, the contact part of the sealing device and the dust-proof ring will have sliding contact, so the dust-proof ring needs to meet a relatively low roughness, and the requirement for the dimensional accuracy of the dust-proof ring is also high. Therefore, the manufacturing cost of the sealing device is high.

[0037] In order to reduce the cost of the sealing device, the embodiment of the present invention provides a bearing and a sealing device. The technical solution in the embodiment of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiment of the present invention. Obviously, The described embodiments are only some, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com