Device for measuring friction moment of rotating pair

A friction torque and rotating pair technology, applied in the field of rotating pair friction torque measurement, can solve the problems of parts damage, low precision, low accuracy and stability, etc., and achieve simple data processing, high measurement accuracy and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

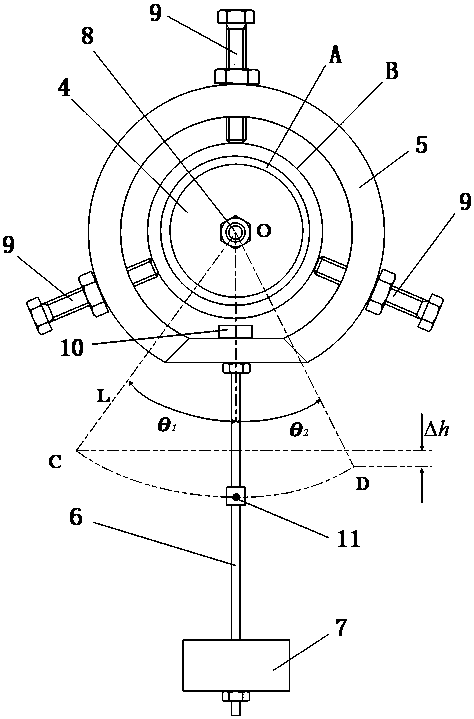

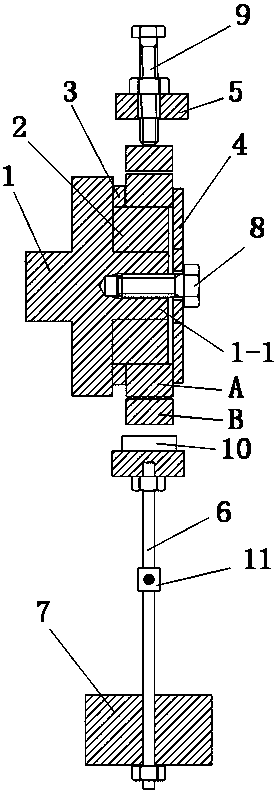

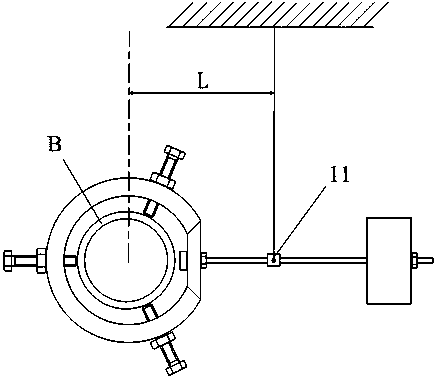

[0033]A device for measuring the frictional moment of a rotary pair, the rotary pair includes an outer ring and an inner ring, the inner ring is sleeved in the outer ring, and the outer ring and the inner ring can rotate relatively, the innovation of which is that the device includes a bracket 1. Support sleeve 2, inner baffle 3, outer baffle 4, chuck 5, swing rod 6, pendulum 7, baffle screw 8, multiple pressing screws 9 and angle sensor 10; the position of the bracket 1 is fixed , the side of the bracket 1 forms a mounting surface, the mounting surface is provided with a support column 1-1, the axial direction of the support column 1-1 is parallel to the horizontal direction; the support sleeve 2 is sleeved on the support column 1-1, The outer diameter of the support sleeve 2 matches the inner diameter of the inner ring, and the outer end surface of the support sleeve 2 is provided with threaded holes; diameter matching, the outer diameter of the inner baffle 3 is smaller tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com