An online measurement system for material particles

A particle and material technology, applied in the field of gunpowder, can solve the problems of toxicity, collision and extrusion, and hidden dangers of gunpowder dust, and achieve the effect of improving measurement accuracy and continuity, high precision and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

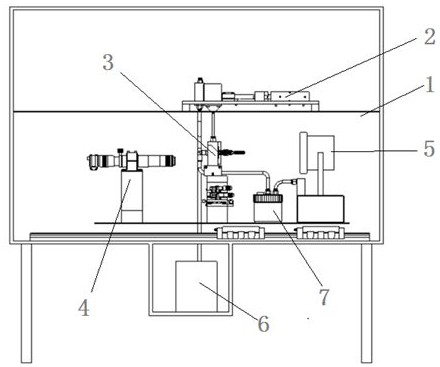

[0036] The system structure of the present invention is as figure 1 As shown, in order to better implement online measurement, the whole system is divided into three layers. In the whole support frame, the upper layer is used to set the automatic feeding mechanism, the middle layer is used to set the automatic measuring instrument, and the lower layer is used to place the recovery bin.

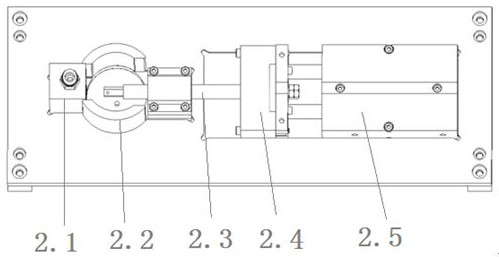

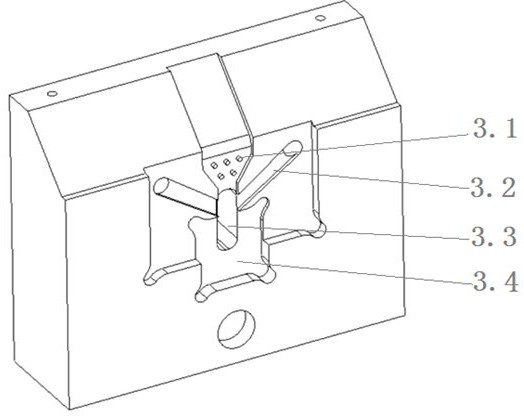

[0037] Such as figure 2 As shown, the automatic retrieving mechanism mainly includes a feeding bin, a discharging funnel and a retrieving rod; the three are on the same horizontal plane, and are arranged symmetrically on the same axis with the center.

[0038] One end of the retrieving rod is connected to the cylinder, and the power output of the cylinder can make the retrieving rod reciprocate on its axis; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com