A portable tensile stress electrochemical corrosion device for metal materials

A technology of stress corrosion and tensile stress, applied in measuring devices, analysis materials, weather resistance/light resistance/corrosion resistance, etc., can solve the problems of small corrosion area, tensile stress corrosion, and shape limitation of tensile specimens, etc., to achieve The effect of simple operation, accurate result analysis and convenient loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A further detailed description will be made below in conjunction with the accompanying drawings.

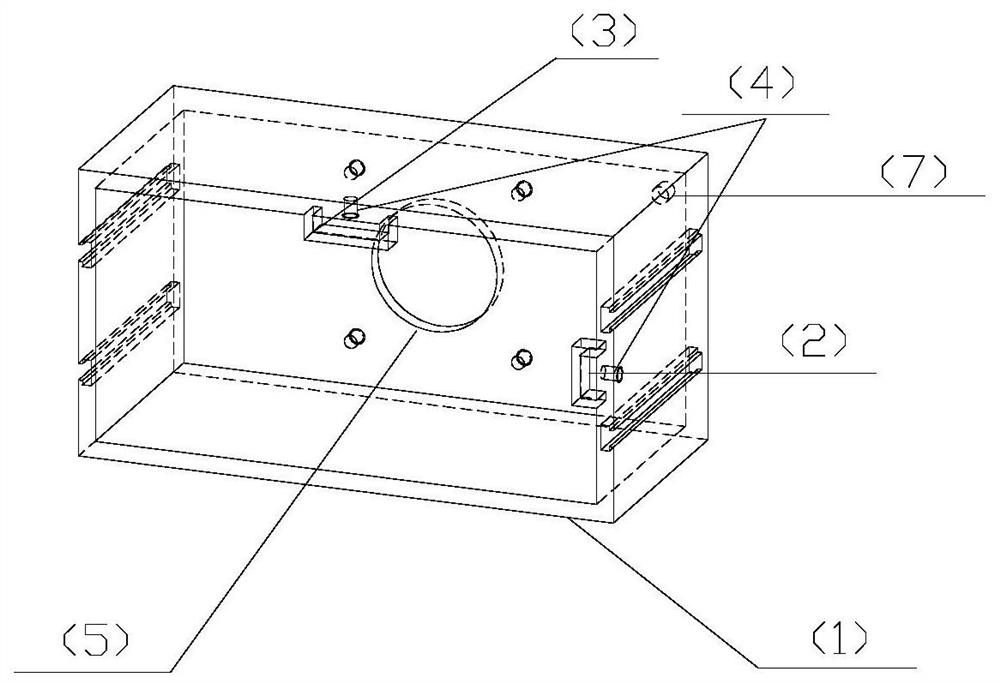

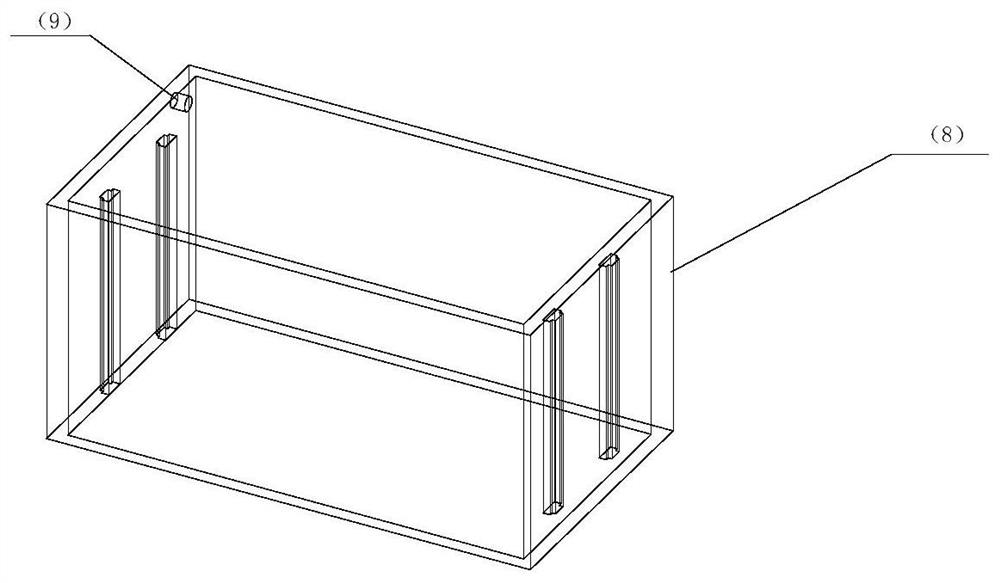

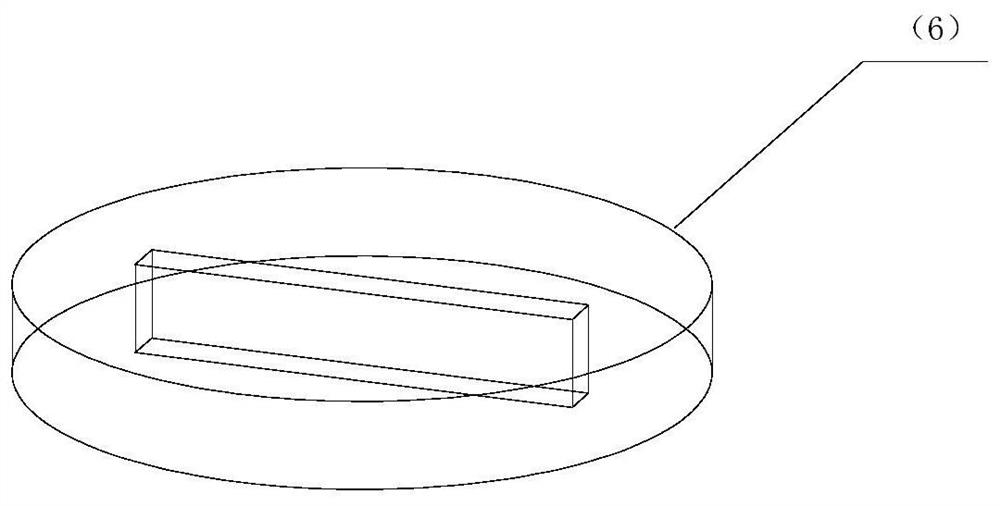

[0023] As shown in the figure, the structural components of a metal material tensile stress electrochemical corrosion tank device are mainly composed of (1) stress corrosion container (2) platinum electrode tank (3) calomel electrode tank (4) plastic fastening screws (Rubber gaskets can be added to prevent liquid leakage) (5) columnar test tank (7) composed of corrosion liquid injection holes.

[0024] Its installation process shows:

[0025] 1. Fix the sample through the fixture of the tensile testing machine to ensure that the tensile force on the sample is at the same level, and select a suitable test tank according to the shape and size of the sample. According to the height limit of the liquid tank device and the screw, the sample selection range is 50mm≤L≤1000mm.

[0026] 2. Connect (1) the stress corrosion container with the tensile testing machine through four sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com