Electrolytic bath device and method for evaluation of metal and coating film corrosion resistance

An evaluation method, electrolytic cell technology, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problem of fast, convenient, selective corrosion, repeated use, Easy to disassemble, quick evaluation, unable to meet the needs of quick evaluation, large amount of corrosive medium, etc., to achieve the effect of facilitating test analysis, rapid evaluation of protection performance, and multiple test conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

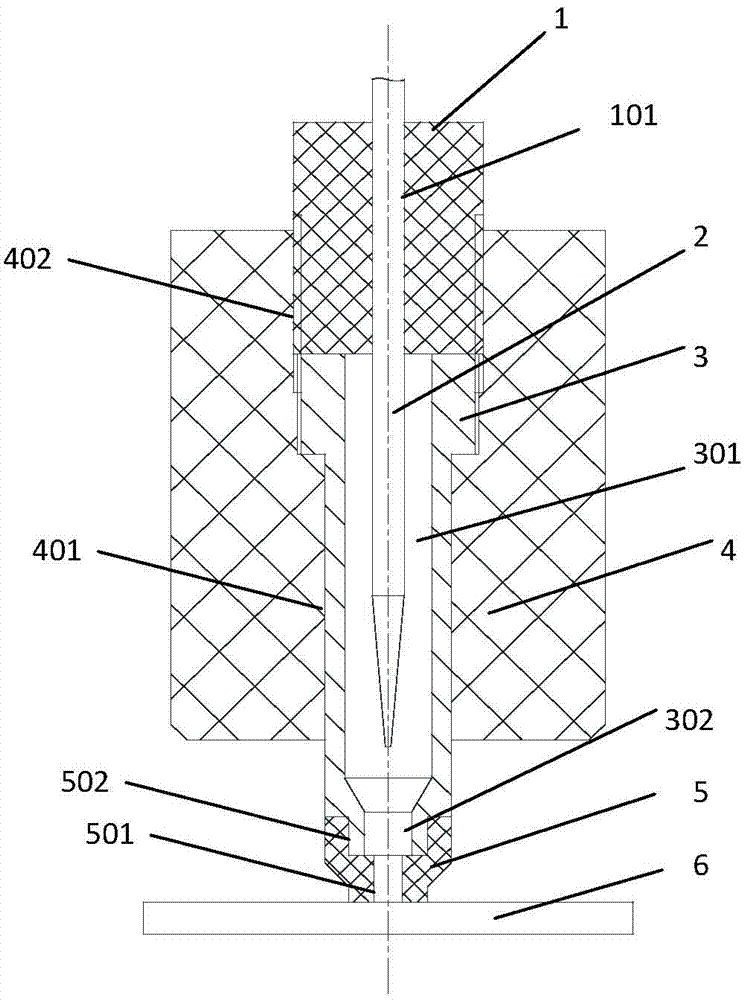

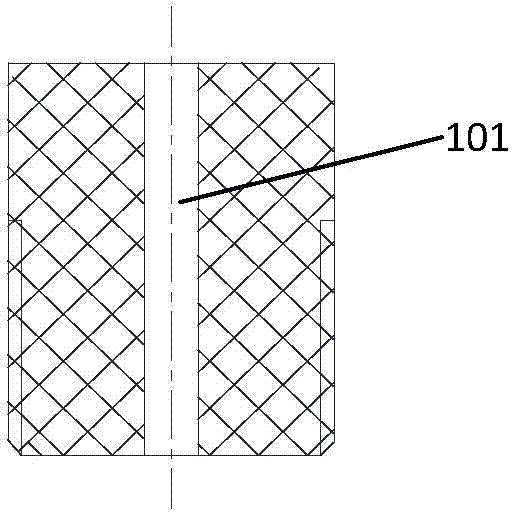

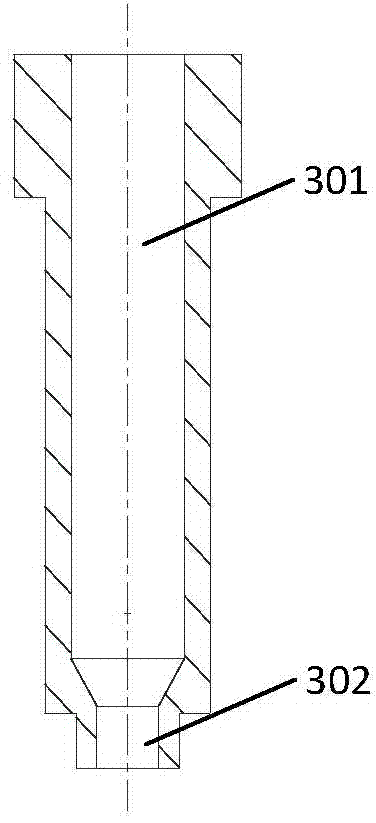

[0035] An electrolytic cell device for evaluating the corrosion resistance of metals and coatings, which can quickly evaluate the corrosion resistance electrochemical parameters of metal materials and coatings and their corrosion resistance, such as figure 1 As shown, the device includes a jack nut 1 , a liquid injection pipe 2 , a corrosion electrolytic cell 3 , a fixing column 4 and a contact washer 5 . The jacking nut 1 is a cylindrical structure processed by corrosion-resistant nylon material, and there is a through liquid injection pipe hole 101 near the middle, as figure 2 shown. The liquid injection pipe 2 is a circular structure processed from corrosion-resistant plastic.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com