A Modeling Method for Reticulated Shell Structure

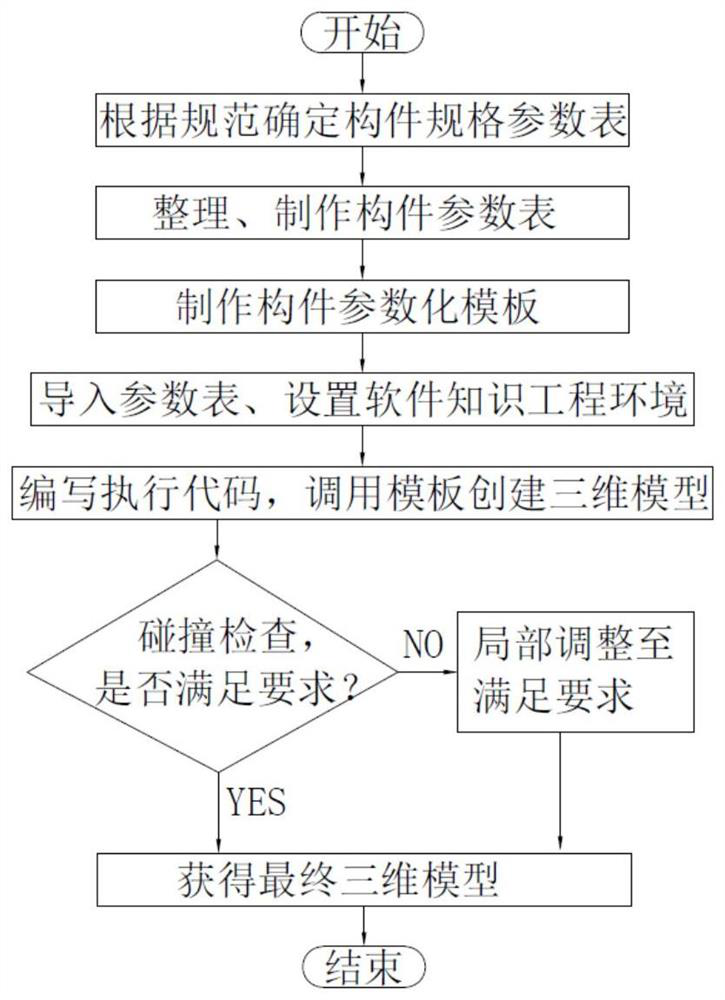

A technology of structural modeling and reticulated shells, applied in the direction of geometric CAD, special data processing applications, etc., can solve the problems that are difficult to guide manufacturing and installation, consume huge manpower and material resources, and difficult to provide useful help for the installation and positioning of components on the construction site. Achieve the effect of guiding the construction of reticulated shells and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

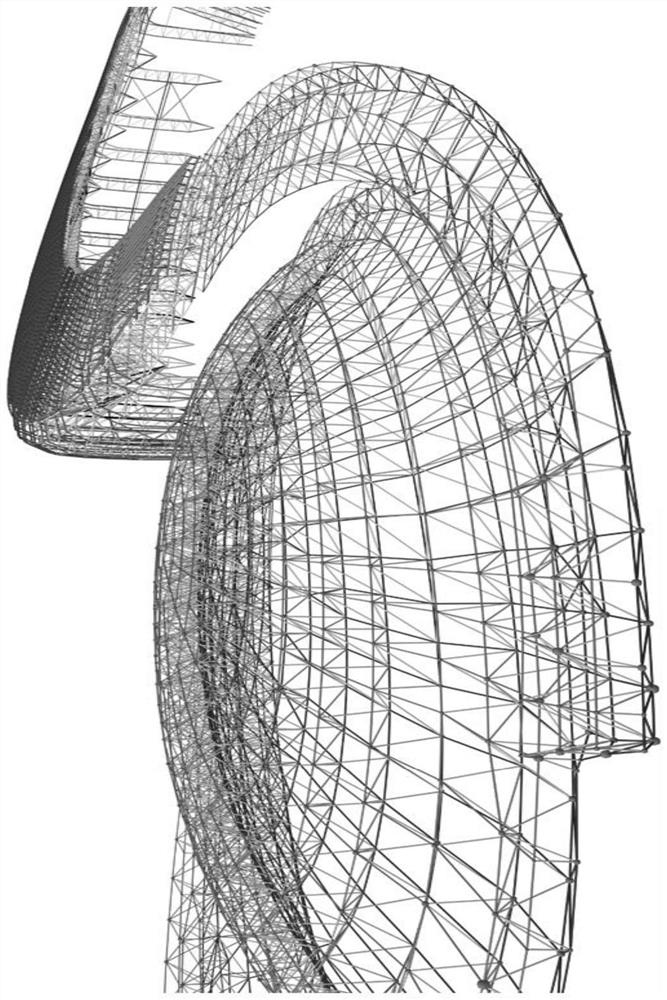

[0063] As mentioned above, the present invention has been successfully applied in the network case structure design of Shaowu Sports Center, Fujian Province, and has achieved good results, such as figure 2 Indicated.

[0064] In summary, the present invention combines the CATIA knowledge engineering function and related specification content compared to the existing net shell structure design method. According to the calculation analysis results, the three-dimensional model of the massive network case structure member can be quickly improved. Modeling efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com