Welding defect feature extraction and welding quality analysis method based on image processing

A welding defect and feature extraction technology, applied in the field of image processing, can solve the problems of welding defect shape size and defect degree without clear and quantitative classification research, and achieve the effect of solving the difficulty of separating the front and back background, improving production efficiency and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further illustrated below in conjunction with specific embodiments, and it should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0049] According to an embodiment of the present invention, a method for feature extraction of welding defects and analysis of welding quality based on image processing is provided.

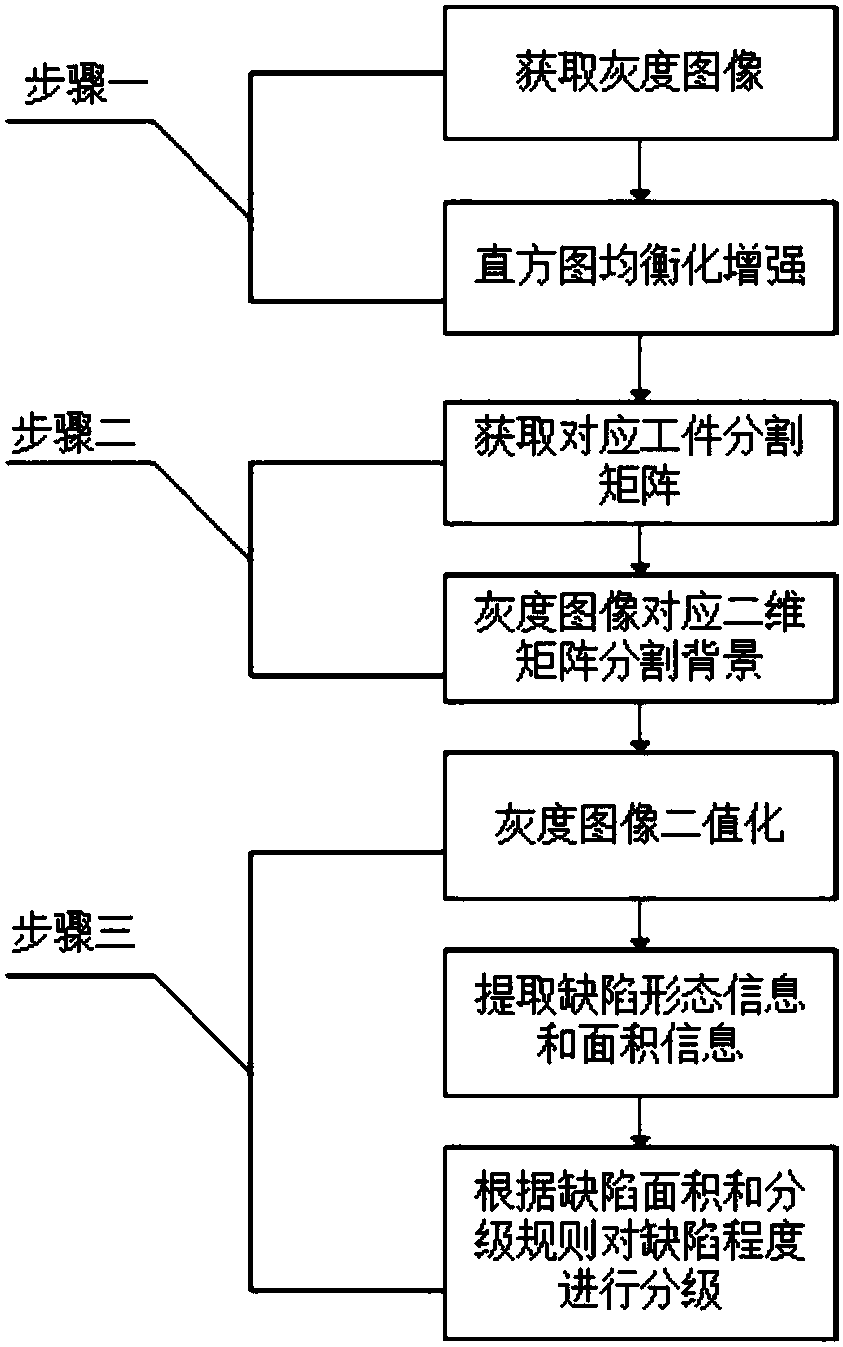

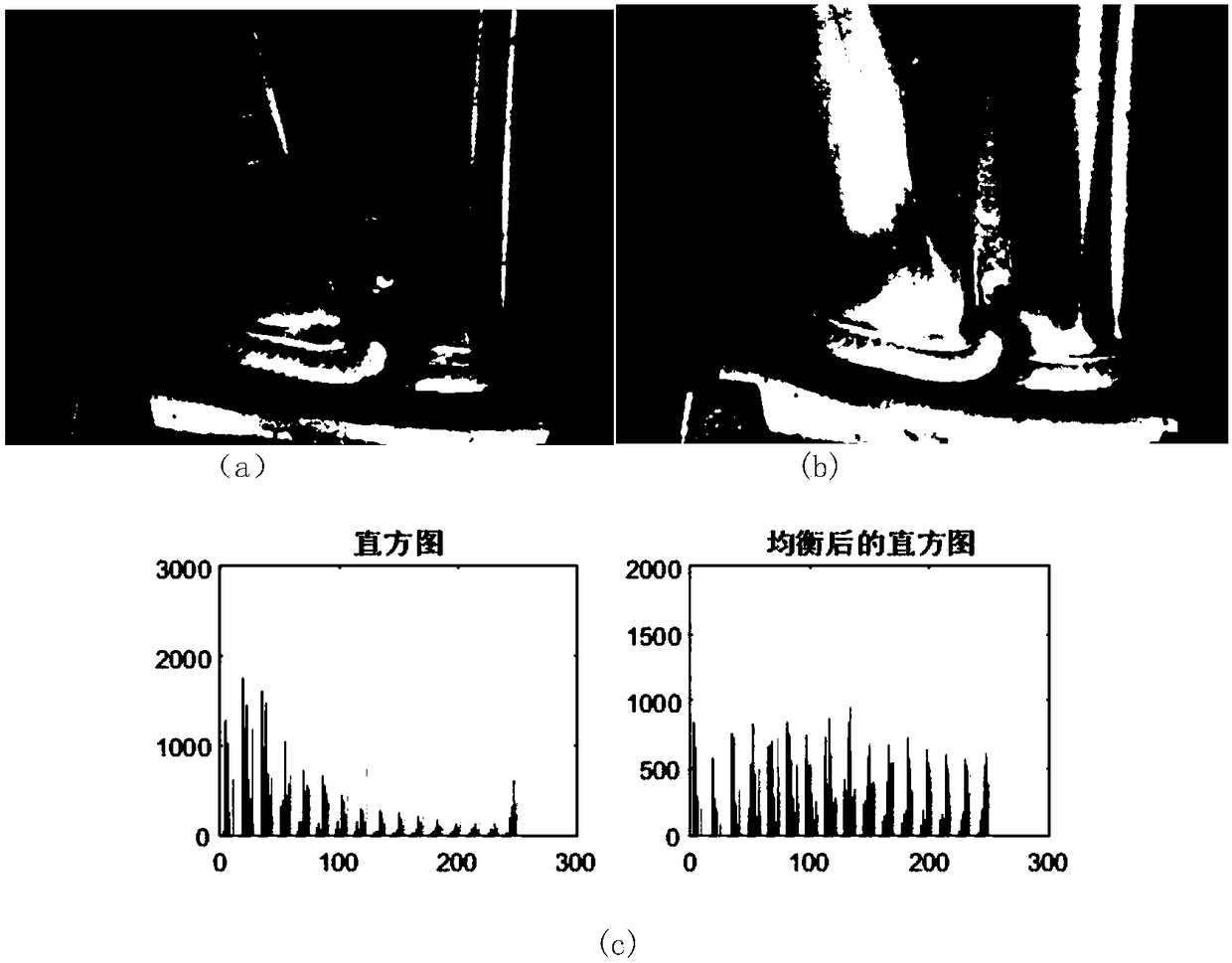

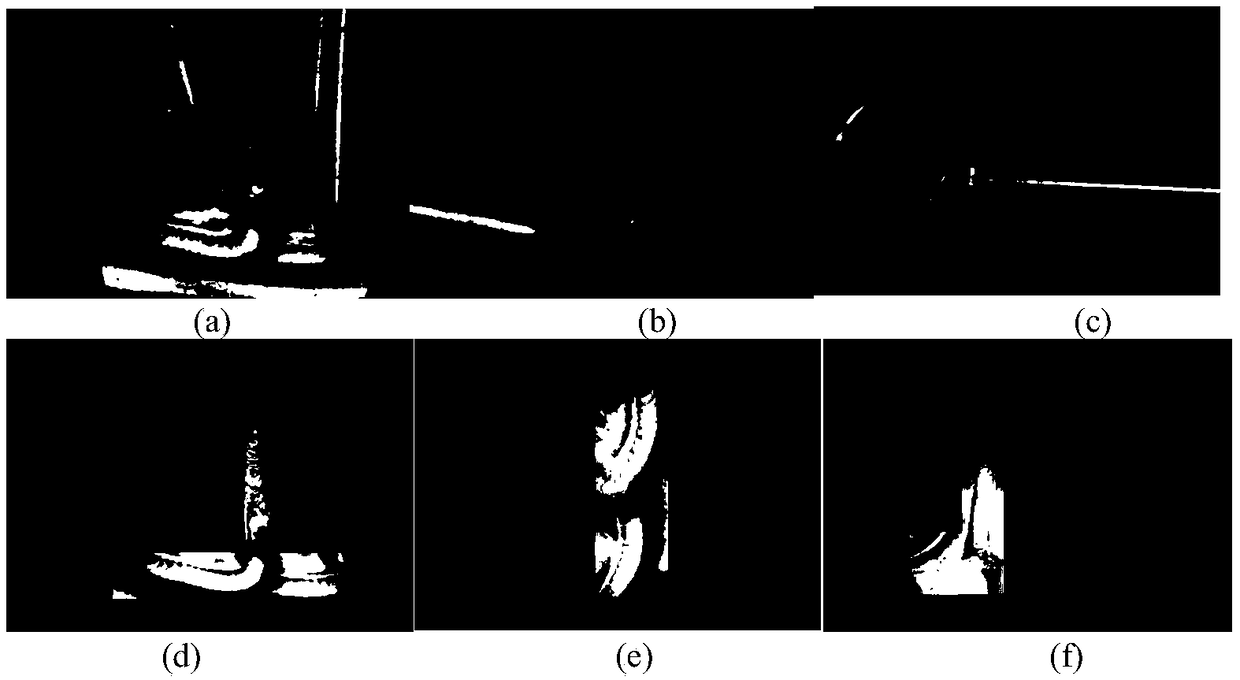

[0050] In a nutshell, after the welding image is collected, the method uses image processing techniques such as image enhancement, background segmentation, binarization processing, and contour extraction to extract the characteristics of welding defects in the workpiece after welding, and calculate the defect area. Perform automatic grading.

[0051] The following will combine figure 1 Each step of the method is described in detail.

[0052] In step 1, the grayscale image after welding is first collected by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com