A mounting structure for a central motor of an electric bicycle

A technology of electric bicycles and mid-mounted motors, which is applied in the direction of electromechanical devices, electric components, vehicle parts, etc. It can solve the problems of poor waterproof performance, no heat dissipation device and buffer device, and inconvenient disassembly and installation, so as to achieve convenient disassembly and installation. The effect of convenient installation and perfect protection device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

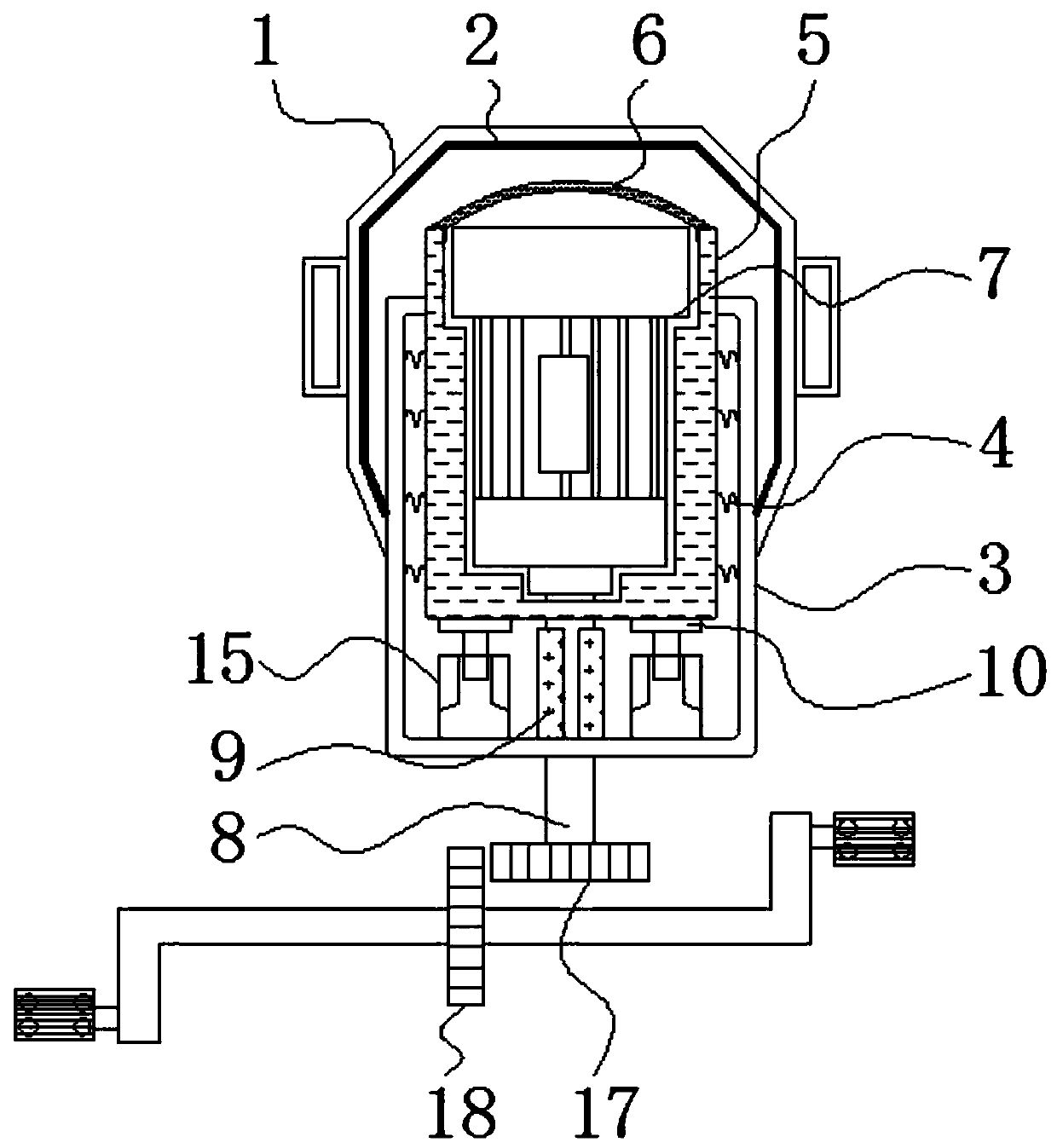

[0021] Example 1, such as figure 1 The middle waterproof layer 2 is pasted on the inner surface of the outer protective shell 1, and the connection mode between the outer protective shell 1 and the inner protective shell 3 is a screw connection, which plays a good role in moisture-proof, keeps the motor body 7 dry, and prevents water damage , the first springs 4 are equidistantly arranged between the inner protective case 3 and the heat-absorbing box 5, and the connection mode between the heat-absorbing box 5 and the motor body 7 is a snap connection, and the connection mode between the heat-absorbing box 5 and the dustproof plate 6 For welding, and the longitudinal section of the dust-proof plate 6 is a circular arc-shaped structure, which prevents the motor body 7 from being damaged due to the back and forth shaking of the bumpy road section, and has a good buffering effect, and the heat-absorbing box 5 can absorb the heat produced by the motor body 7 when it is working. A l...

Embodiment 2

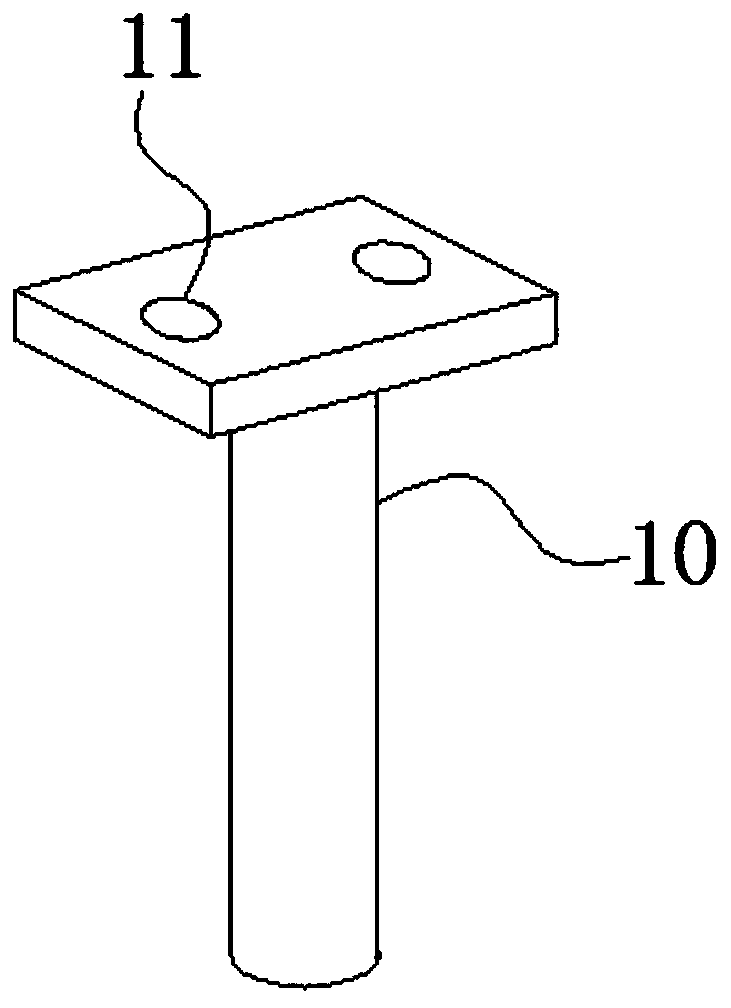

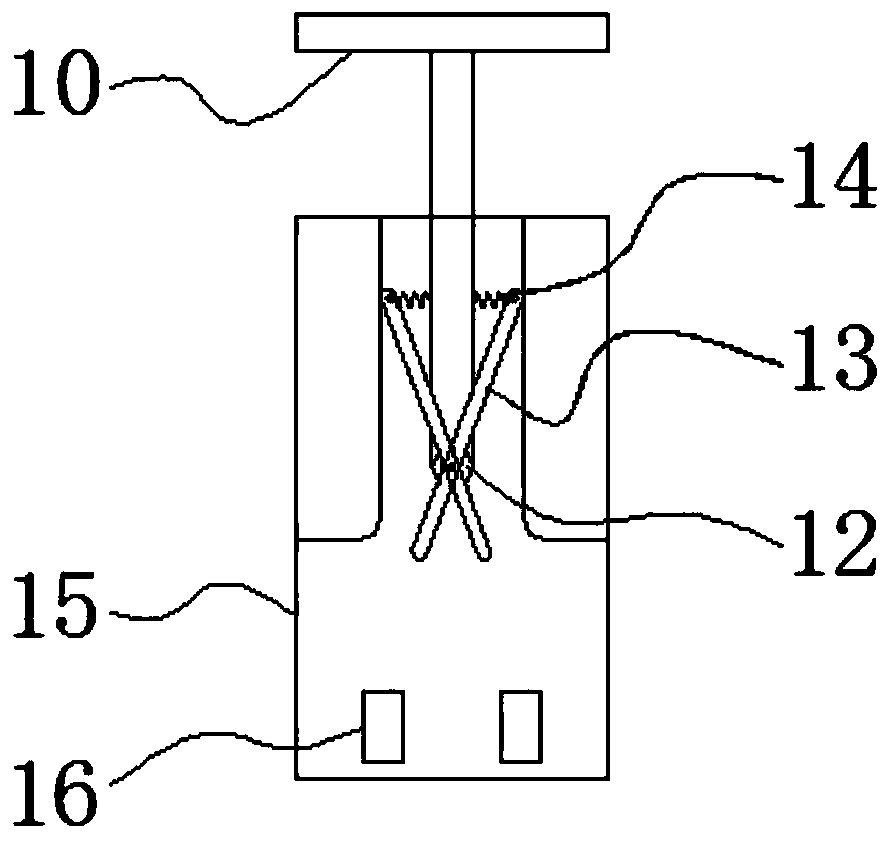

[0022] Example 2, such as image 3 There are two movable rods 13 arranged symmetrically with respect to the mounting block 10, and the movable rods 13 are mutually intersected with respect to the rotating block 12. The movable rod 13 is a rotating structure on the mounting block 10, and the upper end of the movable rod 13 is connected with the second spring 14 The outer surface of the lower end of the mounting block 10 is connected, through the action of the movable rod 13 and the second spring 14, it is convenient to quickly connect the heat absorbing box 5 with the inner protective shell 3, and it is also convenient to separate the two through the action of the push block 16, which is convenient. The maintenance work of the staff in the later period can also clean up the interior.

[0023] Working principle: When using the installation structure of the middle motor of the electric bicycle, firstly, the motor body 7 is snapped inside the heat-absorbing box 5, and the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com