Oscillation mini-channel cookware

A technology of micro-channel and kitchen utensils, applied in the direction of kitchen utensils, household utensils, special materials for cooking utensils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

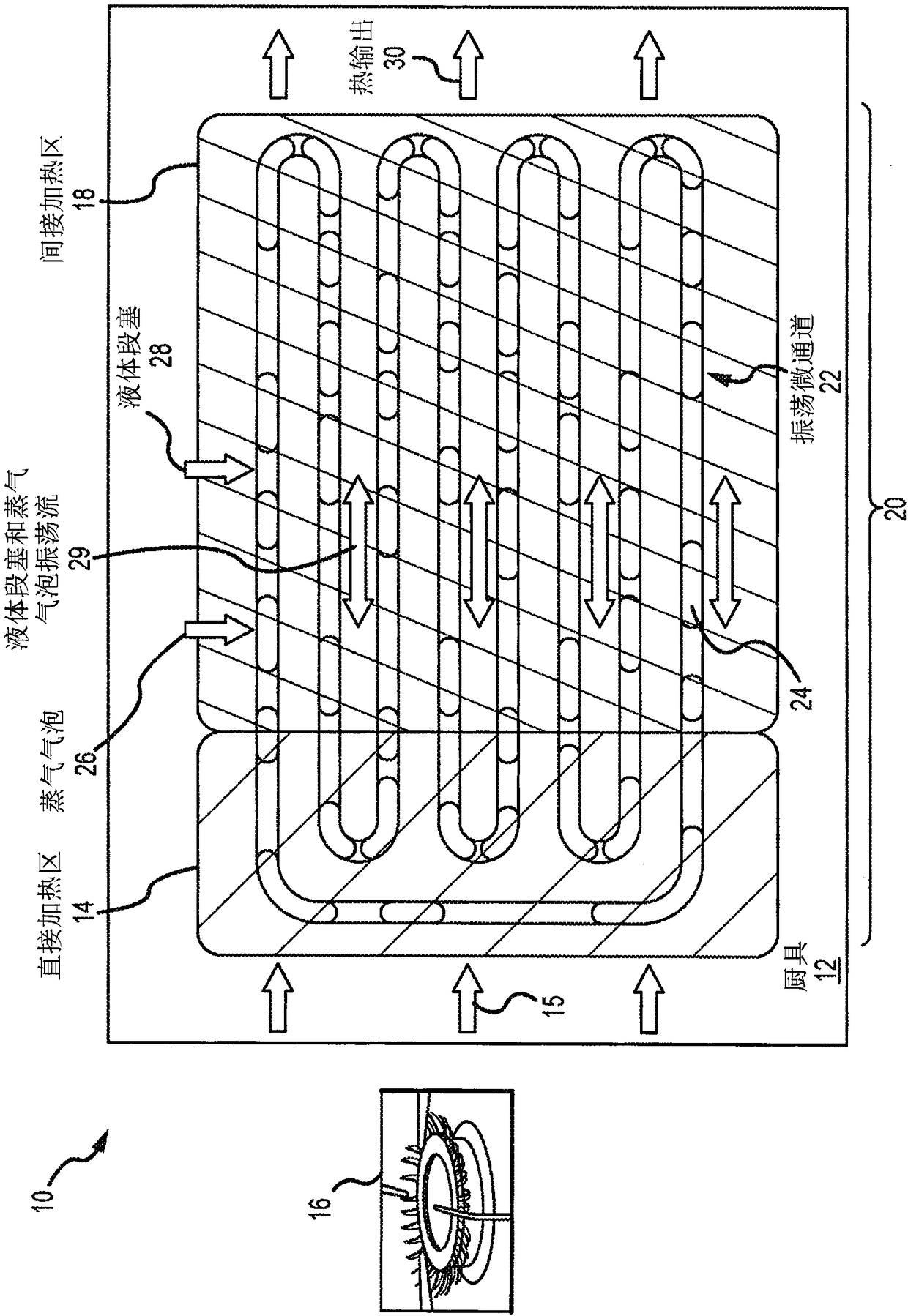

[0023] The present invention provides safe, lightweight and inexpensive cookware with fast thermal response and uniform heating. This is accomplished using oscillating microchannels to transfer heat via convection from the direct heating zone to the indirect heating zone for cooking on both surfaces. In certain embodiments, the oscillating microchannels are "coreless" and are therefore simpler and less expensive to implement safely and efficiently.

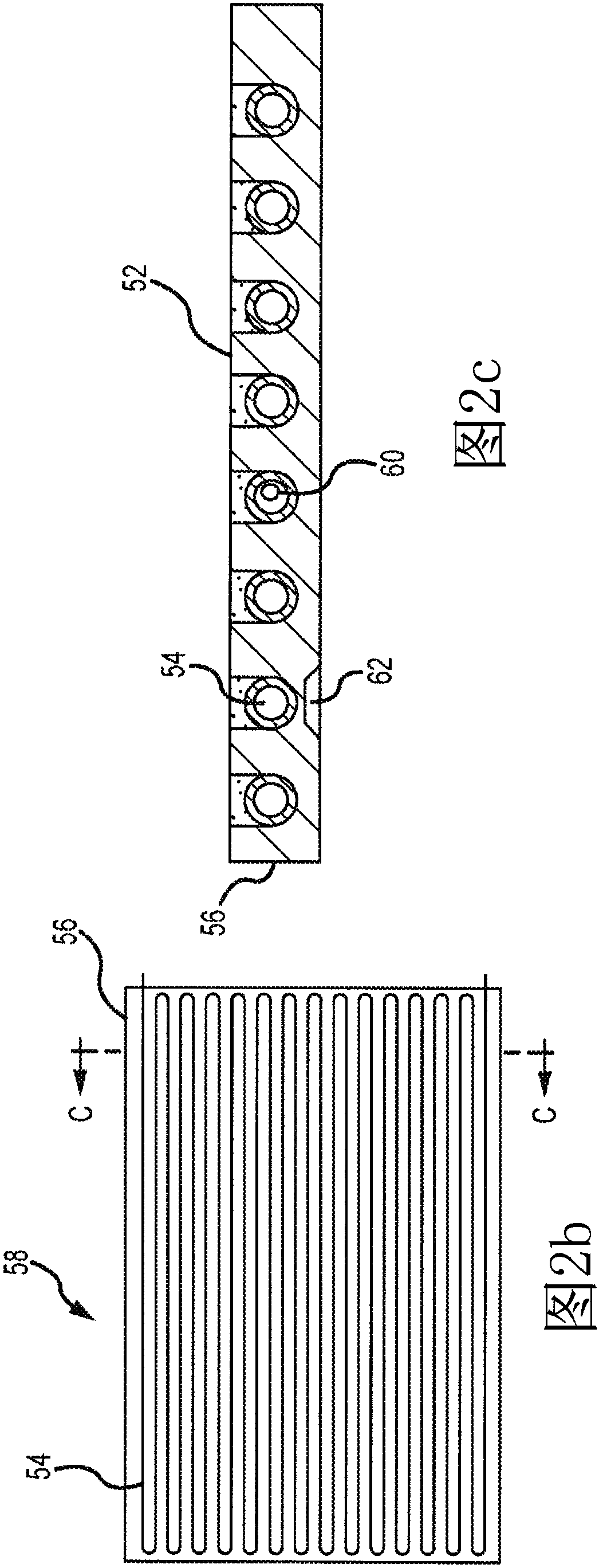

[0024] see figure 1 A kitchen appliance 10 includes a metal plate 12 having a direct heating zone 14 and an indirect heating zone 18 configured to receive thermal energy 15 directly from a heat source 16 . The direct heating zone 14 and the indirect heating zone 18 together define a food heating zone 20 . A "coreless" oscillatory microchannel (OMC) 22 embedded in plate 12 winds back and forth between direct and indirect heating zones. The working fluid 24, which occupies 30-90% of the volume of the oscillating microchannel, is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com