Press sleeve and method of manufacturing the same

A polyol and cross-linking agent technology, applied in the field of press sleeves, can solve the problems of inability to achieve stability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

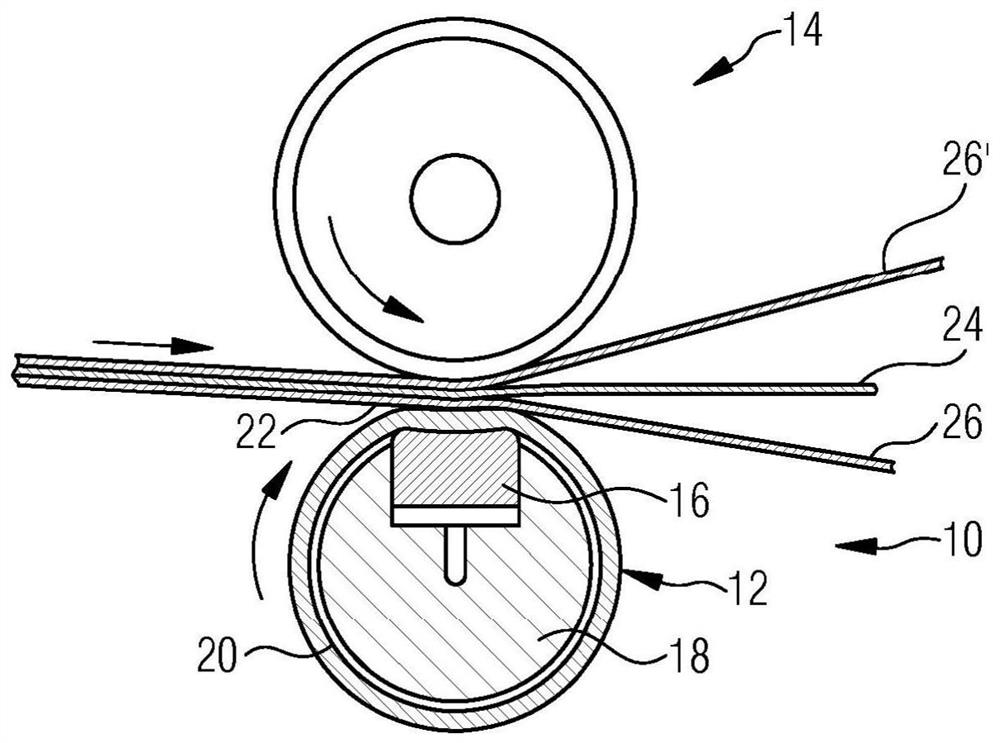

[0046] The back roll 14 here consists of a cylindrically designed roll rotating about its longitudinal axis, while the shoe press roll 12 consists of a shoe 16 , a stationary yoke 18 supporting the shoe 16 and a press sleeve 20 . The shoe 16 and the yoke 18 are fixedly arranged relative to the back roll 14 or the press jacket 20, respectively. This means they do not rotate. In this case, the shoe 16 is supported by a yoke 18 and is pressed by means of hydraulic press elements, not shown, onto a press sleeve 20 surrounding it. The press sleeve 20 , which surrounds the shoe 16 and the yoke 18 in the circumferential direction, rotates here about its longitudinal axis counter to the direction of rotation of the counterroll 14 . Due to the concave configuration of the shoe 16 on its side facing the back roller 14 , a relatively long nip 22 results.

[0047] The shoe press 10 is particularly suitable for dewatering the fibrous web 24 . During operation of the shoe press, the fibr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com