A kind of superhydrophobic nanofiber composite membrane and preparation method thereof for membrane distillation

A nanofiber and composite membrane technology, applied in the field of material engineering, can solve problems such as hindering the popularization and application of membrane distillation technology, pushing up the preparation cost of membrane distillation membranes, expensive hydrophobic modifiers, etc., so as to facilitate solvent recovery and reuse, The preparation method is simple and easy to implement, and the price is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A preparation method of superhydrophobic nanofiber composite membrane for membrane distillation:

[0027] (1) 15 g of polyvinylidene fluoride (PVDF) was dissolved in 85 g of N,N-dimethylformamide (DMF), and stirred at a constant temperature in an oil bath at 80° C. for 24 hours to obtain a uniform and transparent electrospinning solution. Dissolve 0.3 g of atactic polypropylene in 99.7 g of xylene, stir in an oil bath at 99°C for 5 hours at a constant temperature to obtain a uniform and transparent suction-filtered solution, and then cool to 60°C at 30°C for use;

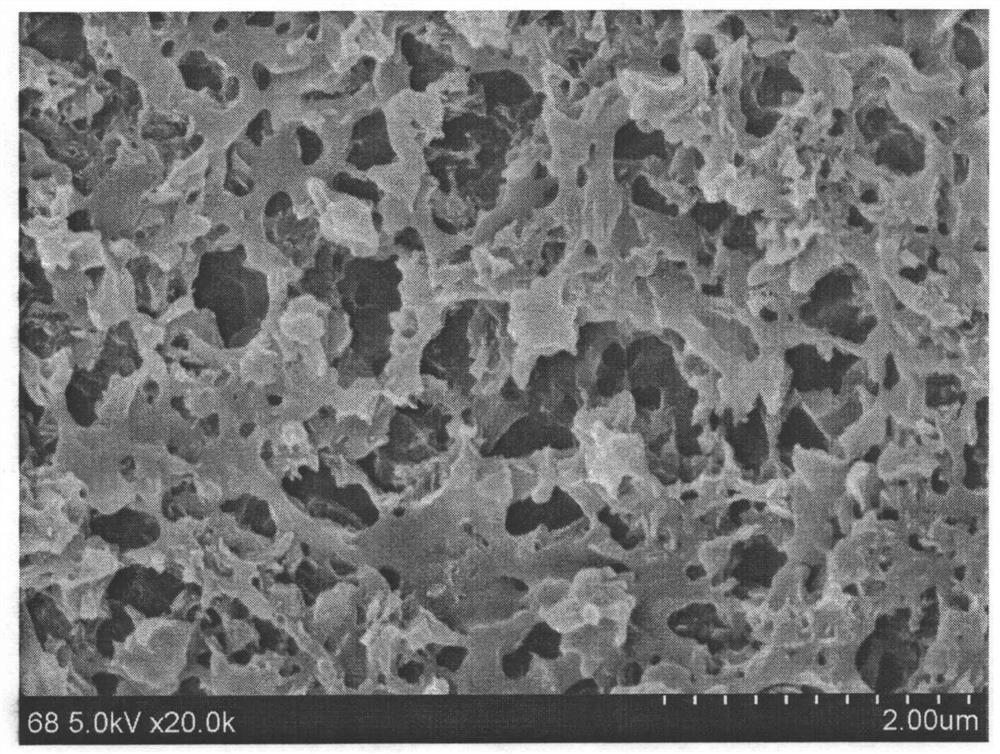

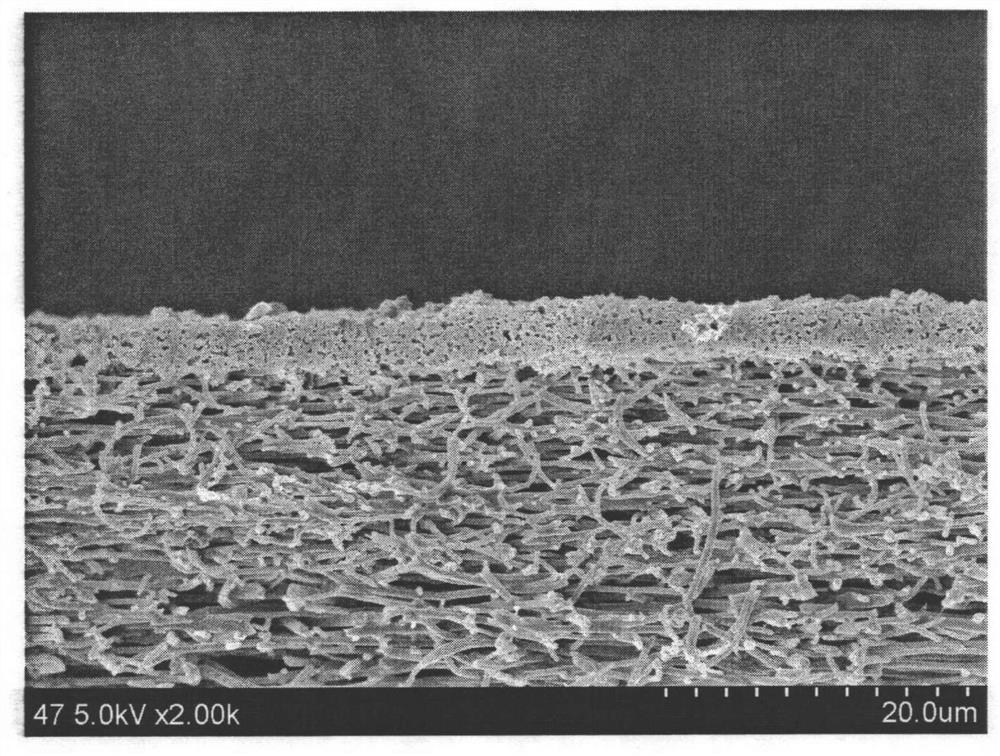

[0028] (2) Add the electrospinning stock solution in (1) into the container, and control the extrusion rate by a micro-injection pump. The extrusion rate of the solution is 5 μL / min. The relative humidity is 36%, the ambient temperature is 31°C, the rotating speed of the receiving drum is 800r / min, and electrospinning is performed, the average diameter of the obtained polyvinylidene fluoride electrospun nanof...

Embodiment 2

[0033] A preparation method of superhydrophobic nanofiber composite membrane for membrane distillation:

[0034] (1) Dissolve 20 g of poly(vinylidene fluoride-co-hexafluoropropylene) in 80 g of N,N-dimethylacetamide as a spinning solution, and stir it in an oil bath at 40°C for 24 hours to obtain a uniform Transparent electrospinning solution. Dissolve 0.3 g of polyethylene in 99.7 g of xylene, stir in an oil bath at 99°C for 5 hours at a constant temperature to obtain a uniform and transparent suction-filtered solution, and then cool it to 50°C at 30°C for later use;

[0035] (2) Add the electrospinning stock solution in (1) into the container respectively, and control the extrusion rate by a micro-injection pump, the solution extrusion rate is 5 μL / min, the eccentric needle is connected to a high-voltage electrode, the voltage is 25kV, and the receiving distance is 15cm , air relative humidity is 32%, ambient temperature is 30 ℃, and receiving drum rotating speed is 700r / mi...

Embodiment 3

[0040] A preparation method of superhydrophobic nanofiber composite membrane for membrane distillation:

[0041] (1) 8 g of polyacrylonitrile was dissolved in 92 g of N,N-dimethylformamide, and stirred at a constant temperature in an oil bath at 50° C. for 6 h to obtain a uniform and transparent electrospinning solution. Dissolve 0.6 g of atactic polypropylene in 99.4 g of cyclohexane, stir in an oil bath at 95°C for 5 hours at a constant temperature to obtain a uniform and transparent suction-filtered solution, and then cool it to 30°C at 20°C for use;

[0042] (2) Add the electrospinning stock solution in (1) into the container, and the extrusion rate is controlled by a micro-injection pump. The extrusion rate of the solution is 16 μL / min. The relative humidity is 36%, the ambient temperature is 31°C, the rotating speed of the receiving drum is 800r / min, and electrospinning is carried out, the average diameter of the obtained polyacrylonitrile electrospun nanofibers is 250nm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com