A kind of method that solid magnesium hydroxide captures carbon dioxide at low temperature

A technology based on magnesium hydroxide and carbon dioxide, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of reaction equilibrium temperature influence, low conversion rate, high energy consumption, etc., to improve chemical adsorption rate, The effect of convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

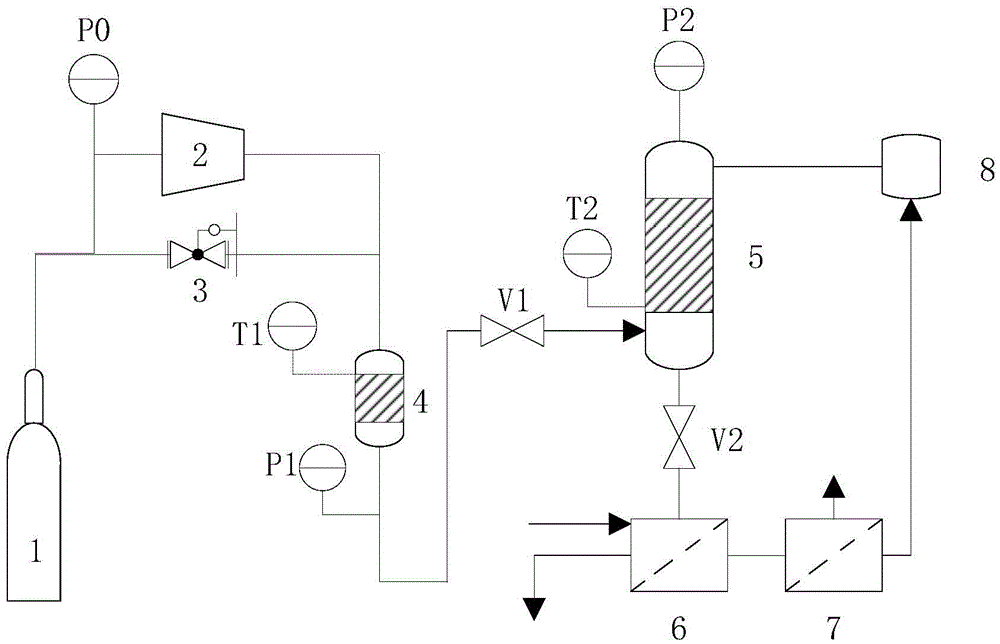

Method used

Image

Examples

Embodiment 1

[0047] Raw materials include: CO 2 (Linde Gas (Xiamen) Co., Ltd., purity > 99.9%, tetraheptyl ammonium bromide [THepAm] [Br] (Shanghai Merrill Chemical Technology Co., Ltd., purity > 99%), magnesium hydroxide (purity 100%) , water (using deionized water).

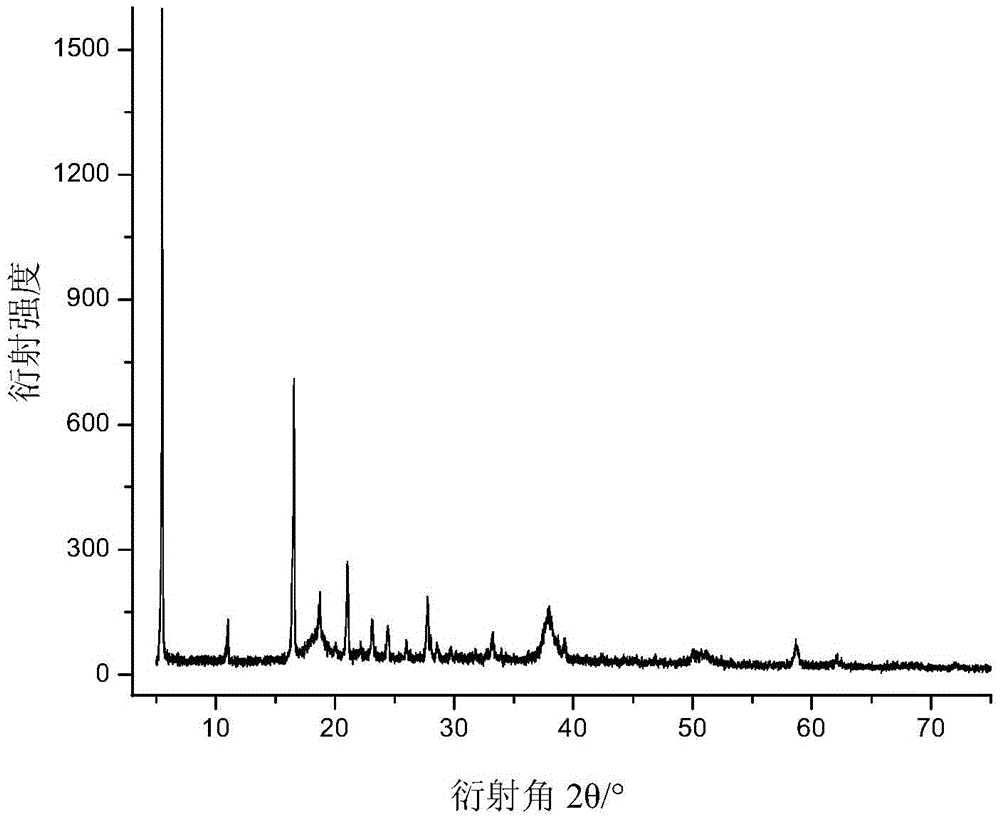

[0048] Mix magnesium hydroxide and tetraheptylammonium bromide with a mass ratio of 1:1 and send them into the high-pressure adsorber. After the high-pressure adsorber is heated to 50°C, the carbon dioxide delivery part is opened so that the carbon dioxide pressure is 15 MPa and enters the high-pressure adsorber. The adsorber was used for chemical adsorption for 30min and 60min respectively. The adsorbent that has absorbed carbon dioxide is released from the high-pressure adsorber, and a small amount of product is taken for analysis and detection. The remaining product is washed with the same volume of water, the ionic liquid is washed into water, and the water is evaporated to recover the ionic liquid.

[0049] figure ...

Embodiment 2

[0051] Raw materials include: CO 2 (Linde Gas (Xiamen) Co., Ltd., purity > 99.9%, tetraheptyl ammonium bromide [THepAm] [Br] (Shanghai Merrill Chemical Technology Co., Ltd., purity > 99%), magnesium hydroxide (purity 100%) , water (using deionized water).

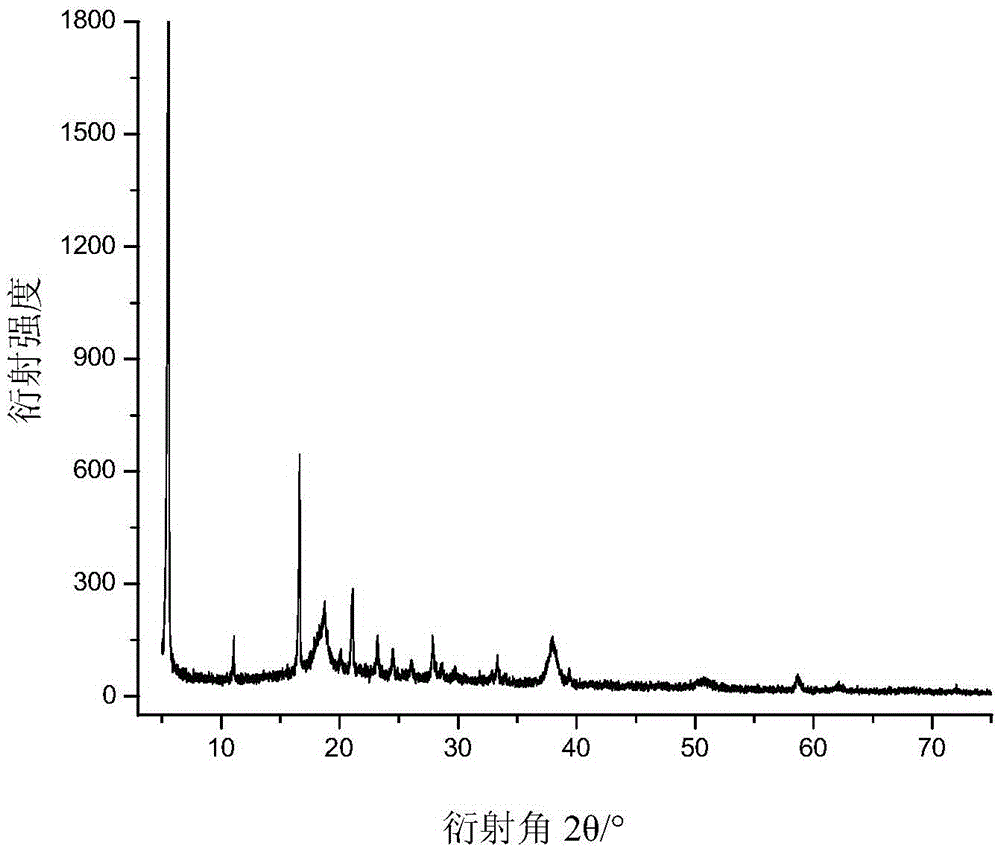

[0052]Mix magnesium hydroxide and tetraheptylammonium bromide with a mass ratio of 2:1 and 4:1 and send them into the high-pressure adsorber, and open the carbon dioxide delivery part after the high-pressure adsorber is heated to 50°C, so that the carbon dioxide pressure is 15MPa , and enter the high-pressure adsorber for chemical adsorption for 60 minutes. The adsorbent that has absorbed carbon dioxide is released from the high-pressure adsorber, and a small amount of product is taken for analysis and detection. The remaining product is washed with the same volume of water, the ionic liquid is washed into water, and the water is evaporated to recover the ionic liquid.

[0053] Figure 4 and Figure 5 The XRD patterns o...

Embodiment 3

[0055] Raw materials include: CO 2 (Linde Gas (Xiamen) Co., Ltd., purity > 99.9%, tetraheptyl ammonium bromide [THepAm] [Br] (Shanghai Merrill Chemical Technology Co., Ltd., purity > 99%), magnesium hydroxide (purity 100%) , water (using deionized water).

[0056] Mix magnesium hydroxide and tetraheptylammonium bromide with a mass ratio of 1:1 into the high-pressure adsorber, and open the carbon dioxide delivery part after the high-pressure adsorber is heated to 50°C, and control the carbon dioxide pressure to 12MPa, 10MPa, 8MPa, 5MPa and into the high-pressure adsorber, chemical adsorption 60min. The adsorbent that has absorbed carbon dioxide is released from the high-pressure adsorber, and a small amount of product is taken for analysis and detection. The remaining product is washed with the same volume of water, the ionic liquid is washed into water, and the water is evaporated to recover the ionic liquid.

[0057] Figure 6-9 The XRD patterns of the reaction products of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com