A device and method for automatically dispensing paste solder

A solder and paste dispensing technology, which is applied in the field of automatic paste solder dispensing equipment, can solve the problems of low operating efficiency of dispensing paste solder, unstable control of solder dosage, and easy omission of operation, etc., to achieve stable positioning, stable solder dosage, The effect of flexible and convenient positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

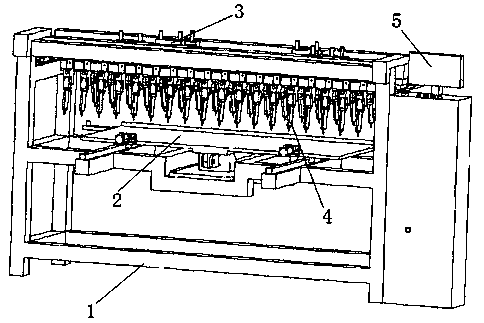

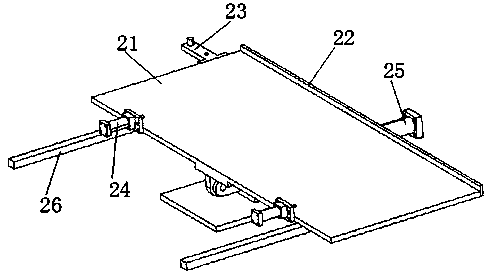

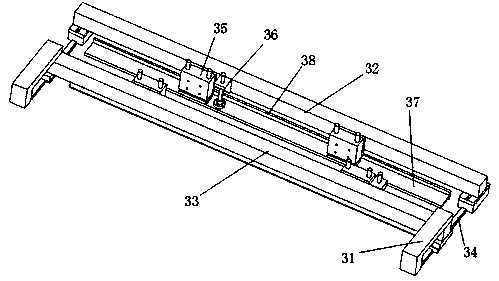

[0029] Such as figure 1 As shown, a kind of equipment for automatically dispensing cream solder according to the present invention is characterized in that it consists of a frame 1, a workbench device 2, a positioning control device 3, a cream solder dispensing device 4, and an automatic control device 5; The frame 1 is a rectangular frame structure with a three-layer structure, the workbench device 2 is located on the middle frame of the frame 1, the positioning control device 3 is located on the uppermost frame of the frame 1, and the point The cream solder device 4 is fixedly installed on the positioning control device 3, and the automatic control device 5 at least includes a programmable logic controller PLC, which is arranged on one side of the frame 1, and is connected to and controls the workbench device 2, positioning The control device 3 and the paste solder dispensing device 4 realize automatic operation of dispensing cream solder, ensure the accuracy and quality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com