Solid tire of shared bicycle

A solid tire, shared bicycle technology, applied in tire parts, reinforcement layers of pneumatic tires, tire tread/tread pattern, etc., can solve the problem of poor comprehensive riding experience, achieve low rolling resistance, return The effect of improving elastic performance and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

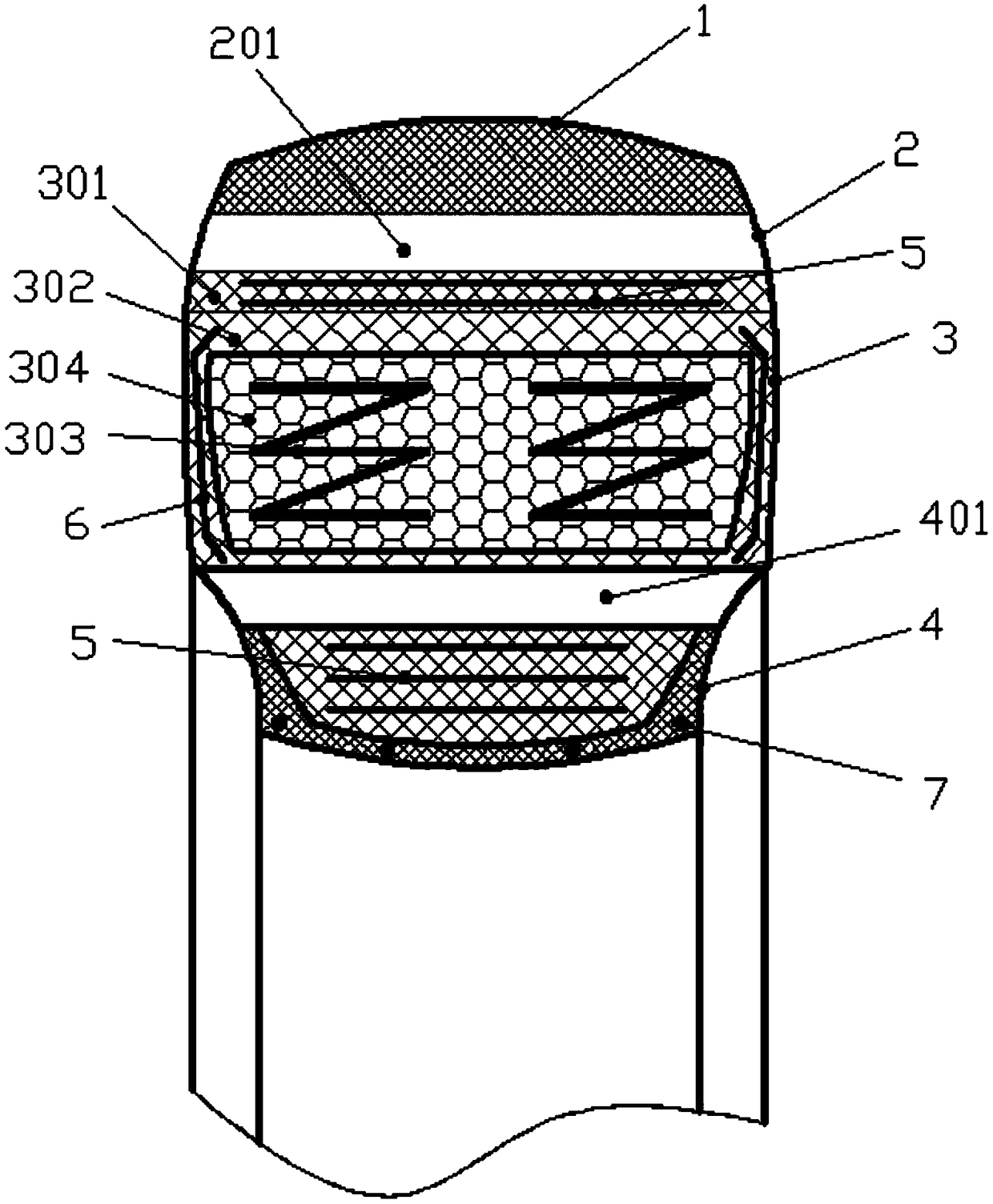

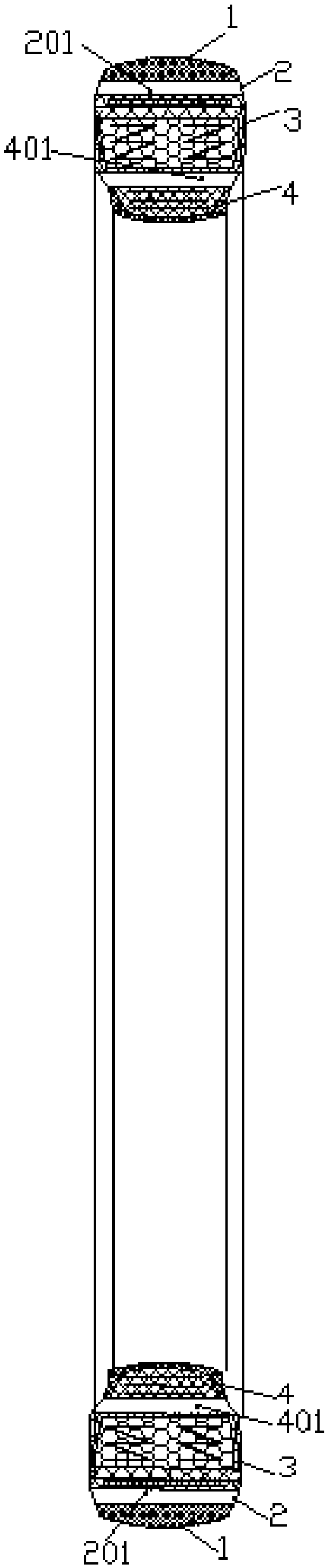

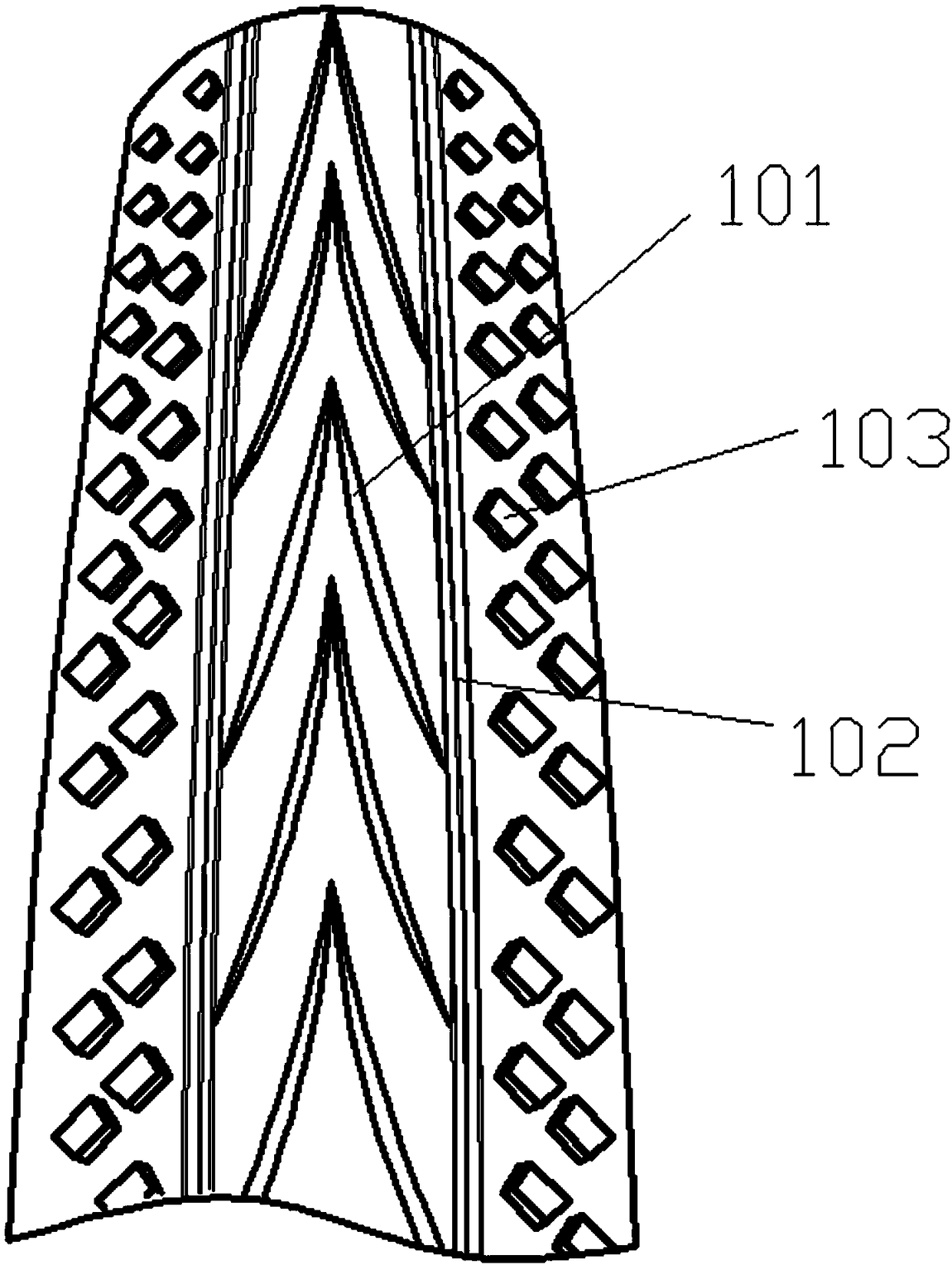

[0021] Attached below Figure 1-5 An embodiment of the present invention is described.

[0022] The shared bicycle solid tire has a solid rubber carcass including a crown 1, a tire shoulder 2, a sidewall 3 and a toe opening 4. Under the prior art, in order to solve the situation that other technical conditions remain unchanged for a solid tire with an integrated solid structure Due to the self-heavy weight that exists under the tire, the larger the subsidence rate of the tire, the problem that the rolling resistance will also increase significantly. The rubber carcass of the present invention adopts a multi-layer composite structure, (such as figure 1 shown) where the crown 1 is a wear-resistant rubber layer; the shoulder 2 adjacent to the crown 1 is concentrically and evenly distributed with a number of first axial through holes 201, and the setting of the first axial through holes 201 plays a buffering role At the same time, under the condition that other conditions remain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com