A kind of protective glue for wafer cutting

A protective glue and wafer technology, applied in the direction of adhesives, epoxy resin glue, non-polymer adhesive additives, etc., can solve the problems of low tensile strength of liquid protective glue, poor adhesion of silicon interface, etc., and achieve silicon interface Good bonding force, strong tensile strength, and the effect of protecting chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

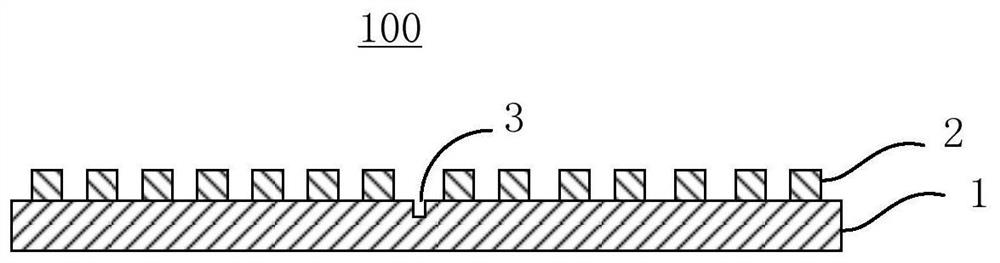

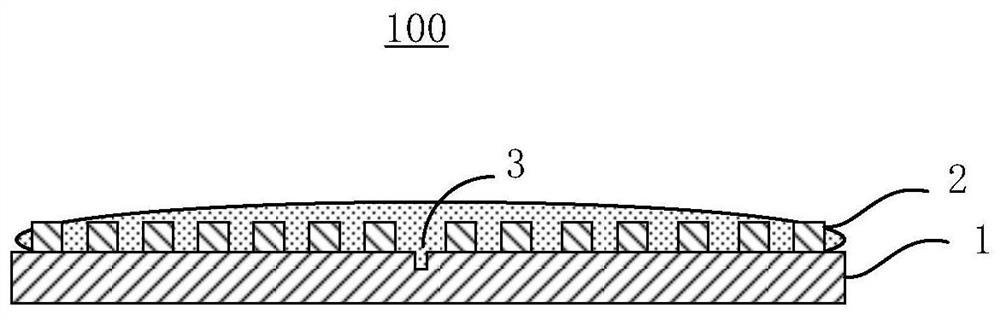

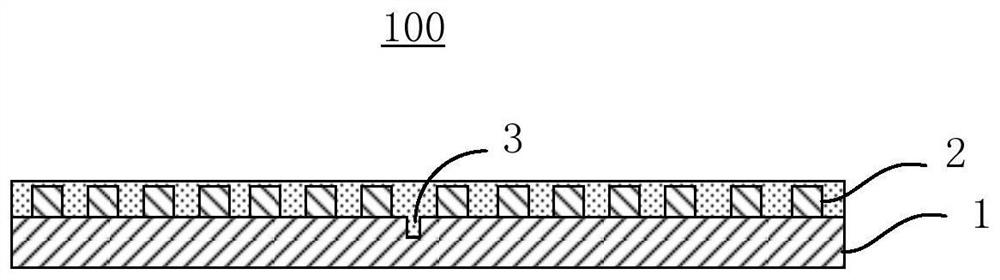

Image

Examples

preparation example Construction

[0042] The present application also provides a method for preparing the protective adhesive for wafer cutting, which comprises the following steps:

[0043] Step S1: providing 15-39 parts by mass of epoxy resin, 10-40 parts by mass of curing agent, 0.1-3 parts by mass of curing accelerator, 35-85 parts by mass of inorganic filler, and 1-4 parts by mass of auxiliary agent And the coupling agent of 0.1-5 mass parts, obtain the mixture after mixing;

[0044] Step S2: grinding the mixture until the mixture becomes a gel, and vacuum defoaming to obtain a protective glue for wafer cutting.

[0045] It can be understood that 0.1-3 parts by mass of a colorant may also be added in the step S1.

[0046] The grinding method in the step S2 is a grinding method known in the art for preparing an adhesive. In at least one embodiment, the mixture is ground using a three-roll mill.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com