All-cotton and high-count seersucker fabric and processing method thereof

A processing method and technology of seersucker, which are applied in the direction of fabric surface trimming, heating/cooling fabrics, and weaving, etc., can solve the problems of unnatural regularity, poor washability of bubbles, and insufficient softness to the hand, so as to improve the handfeel and durability. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

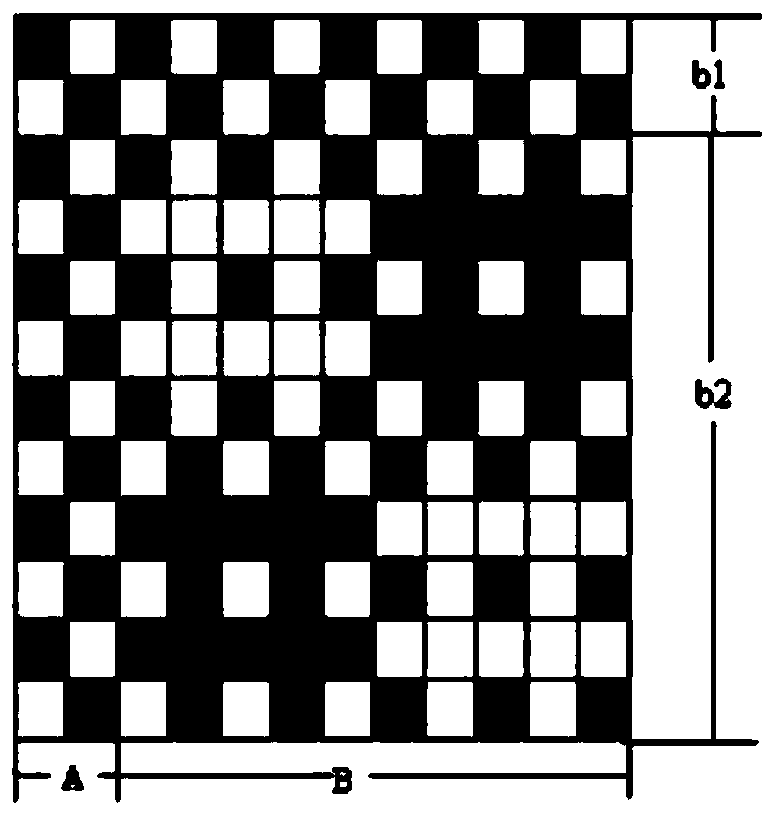

Embodiment 1

[0021] The fabric warp adopts two kinds of yarns: 60S combed and compact spun yarn and 40S combed and compact spun yarn. The 60S yarn is wound on the bubble shaft as the bubble warp, and the 40S yarn is dyed on the ground shaft as the ground warp. The fabric weft is made of 60S combed and compact spun yarn. The fabric presents the appearance of a cloth surface with foaming and non-foaming arranged alternately at intervals of 2 cm along the weft. The foaming part of the fabric is plain weave, and the non-foaming part is fancy through-hole weave, among which the fancy through-hole weave is the joint weave of plain weave and through-hole weave. 2cm are arranged alternately. During the weaving process, the fabric controls the warp let-off tension of the bubble warp and the ground warp, so that the bubble warp weaving shrinkage: the ground warp weaving shrinkage=1.2. The machine specification of the fabric is 105’’ / (JC60S+JC40S)*JC60S / 110*100.

[0022] The printing and dyeing pr...

Embodiment 2

[0024] 80S combed and compact spun yarns and 60S combed and compact spun yarns are used as the warp yarns. The 80S yarns are wound on the bubble shaft as the bubble warp, and the 60S yarns are dyed on the ground shaft as the ground warp. The fabric weft is made of 80S combed and compact spun yarn. The fabric presents the appearance of a cloth surface with foaming and non-foaming arranged alternately at intervals of 4 cm along the weft. The foaming part of the fabric is plain weave, and the non-foaming part is fancy through-hole weave, among which the fancy through-hole weave is the joint weave of plain weave and through-hole weave. 4cm are arranged alternately. During the weaving process, the fabric controls the warp let-off tension of the bubble warp and the ground warp, so that the bubble warp weaving shrinkage: the ground warp weaving shrinkage=1.4. The machine specification of the fabric is 105’’ / (JC80S+JC60S)*JC80S / 150*120.

[0025] The printing and dyeing processing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com