Paperboard production process

A production process and cardboard technology, which is applied in the field of cardboard manufacturing, can solve the problems of inconvenient storage of pulp, affecting the quality of grinding, and blockage of the lower hopper, so as to improve the efficiency and quality of grinding, prevent internal blockage, and prevent blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

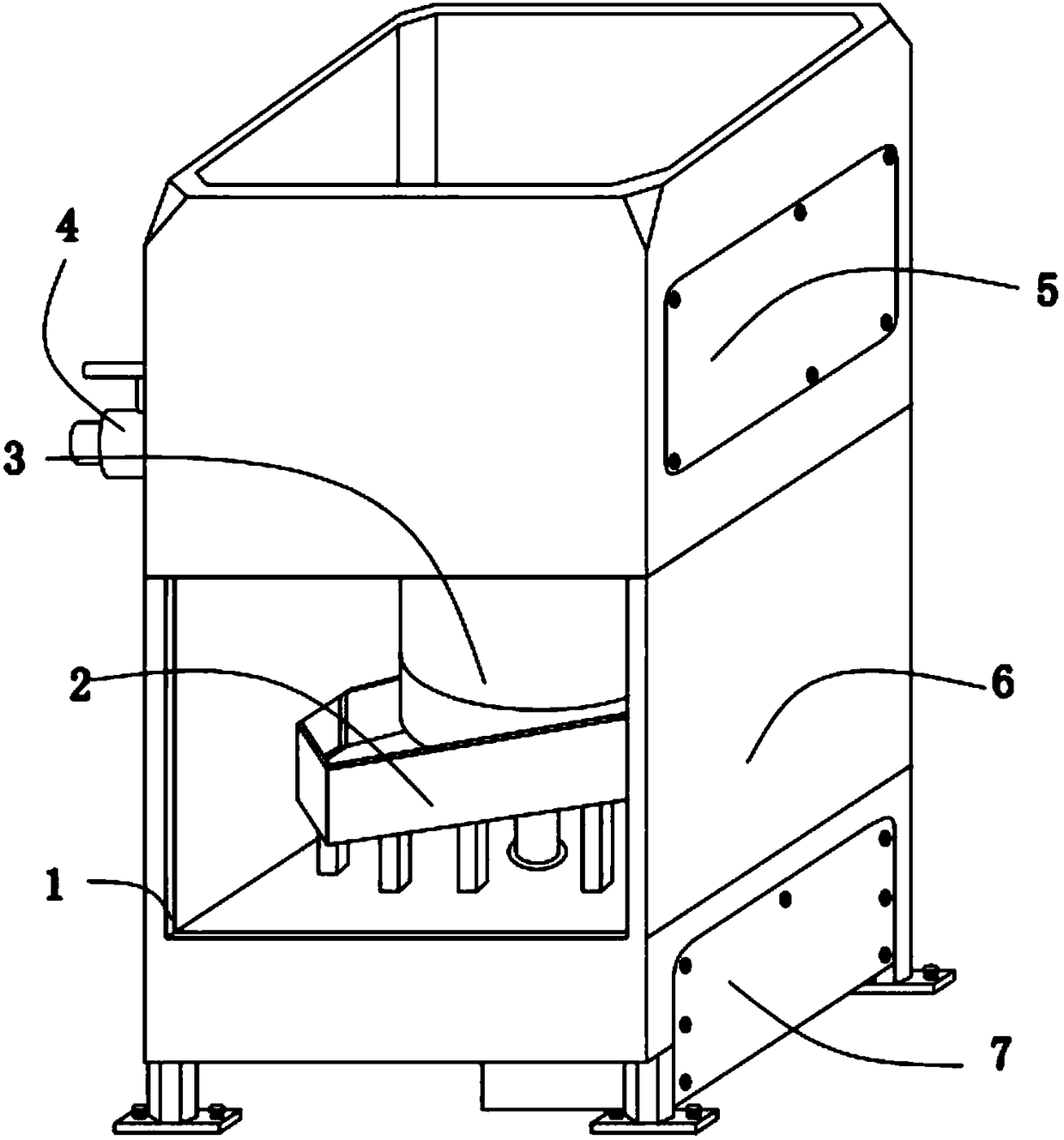

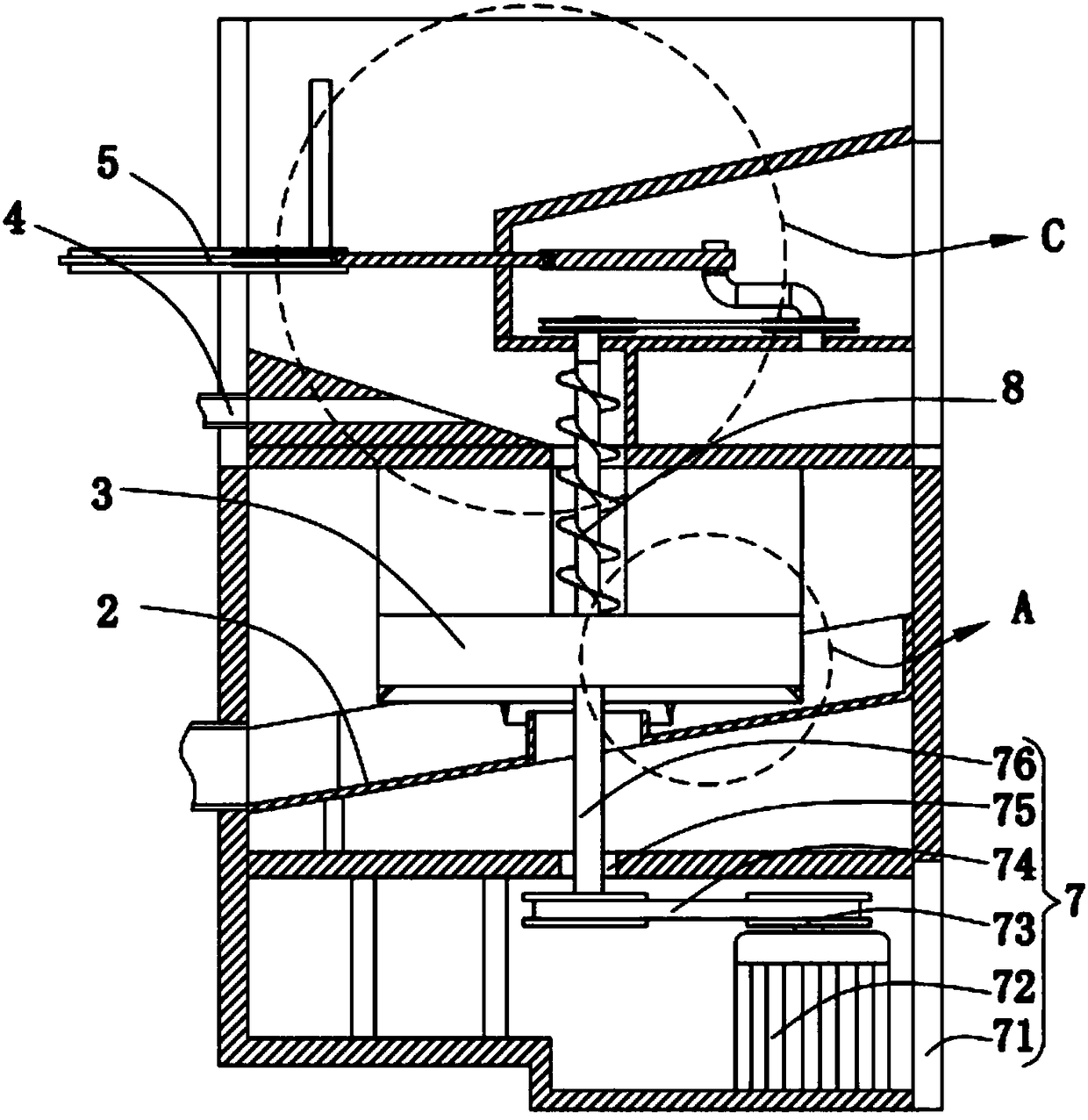

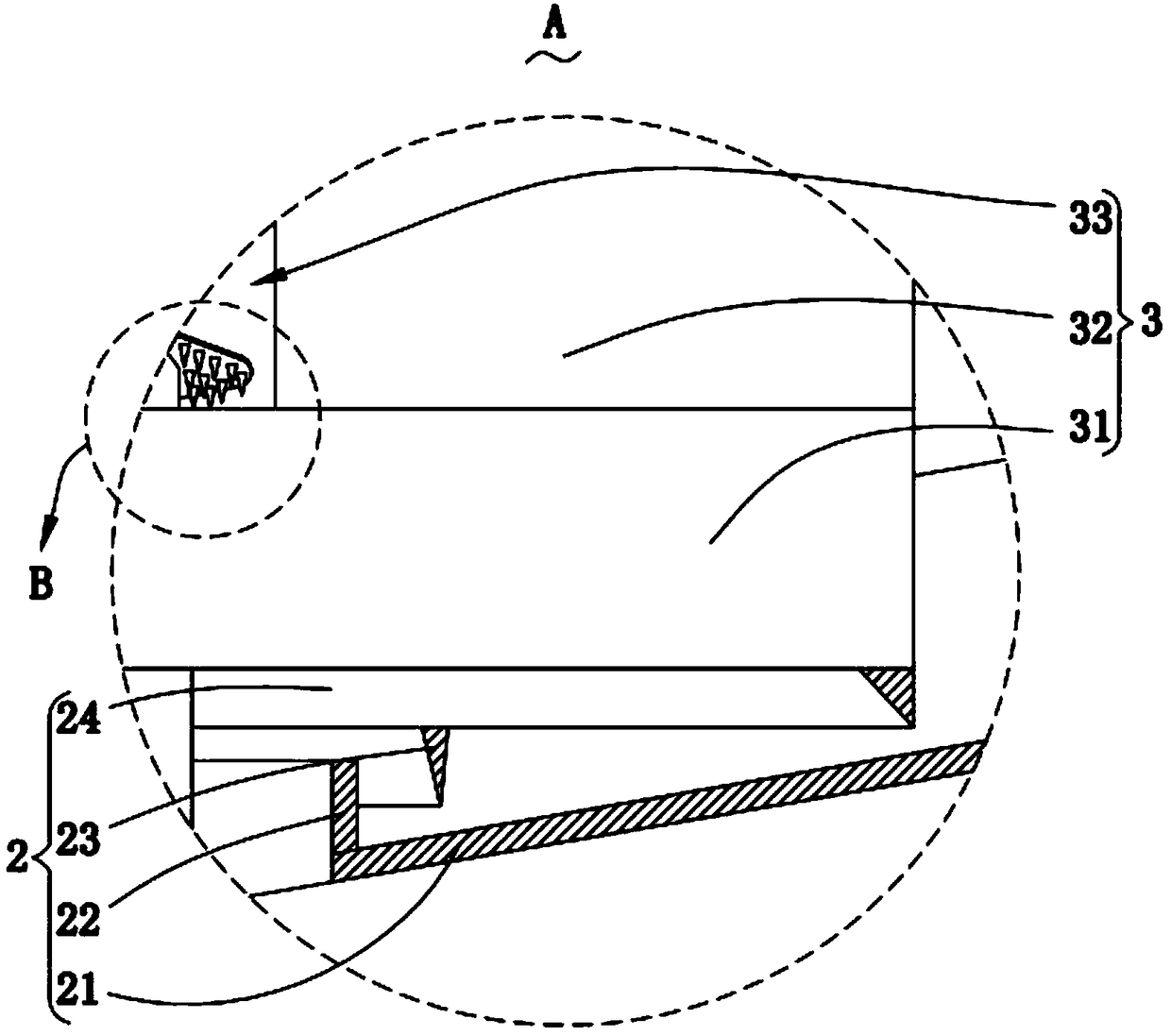

[0031] Such as figure 1 , figure 2 and Figure 5 Shown, a kind of cardboard production technique of the present invention, this technique comprises the following steps:

[0032] Step 1: send the raw material slurry into the pulp washing box, and remove sand from the slurry;

[0033] Step 2: sending the slurry in step 1 into a refiner for refining;

[0034] Step 3: Send the slurry in step 2 to the next process;

[0035] The refiner described therein comprises an access panel 1, a guide structure 2, a grinding structure 3, a water inlet valve 4, a blanking structure 5, a casing 6, a driving structure 7 and an anti-blocking structure 8; the side wall of the casing 6 The access panel 1 for maintenance is provided, and the access panel 1 is detach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com