Environment-friendly drilling fluid integrated treatment system based on multi-stage purification

A treatment system and drilling fluid technology, applied in water/sewage multi-stage treatment, mining wastewater treatment, water/sludge/sewage treatment, etc., can solve the problems of screening out, difficult centrifugal separation, affecting treatment efficiency, etc., to achieve Avoid internal blockage, avoid the effect of processing dead ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

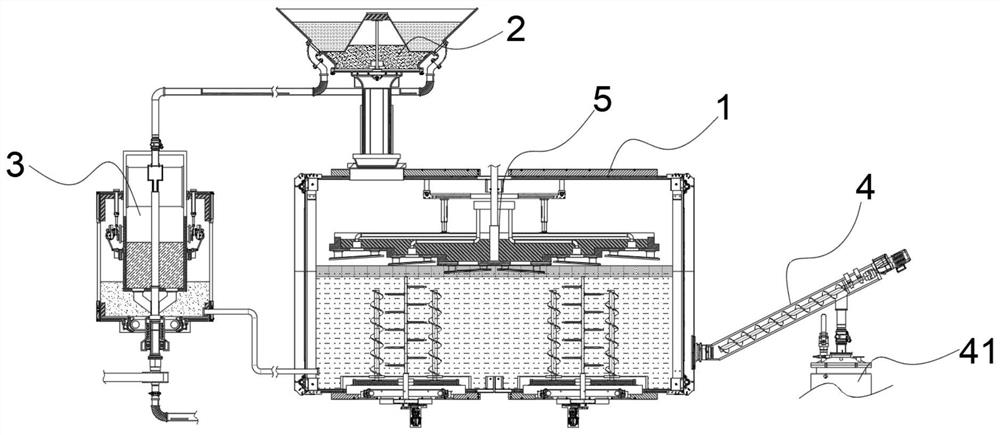

[0060] see figure 1 , in the embodiment of the present invention, an environment-friendly drilling fluid integrated treatment system based on multi-stage purification, which includes:

[0061] Main integration box 1;

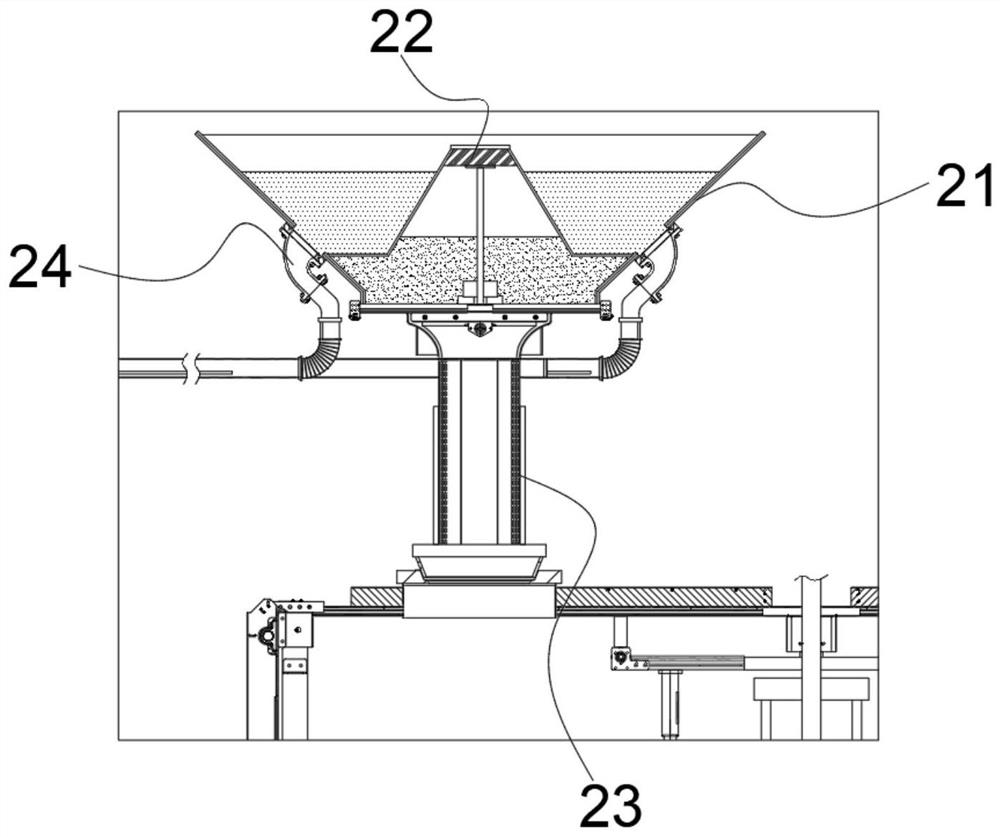

[0062]The feed primary treatment assembly 2 is vertically connected to one side of the main integration tank 1, and the feed primary treatment assembly 2 is used for the preliminary filtration treatment of the drilling fluid, so that the dilute mixed turbid fluid in the drilling fluid can be filtered and discharged. Sent to the main integration box 1;

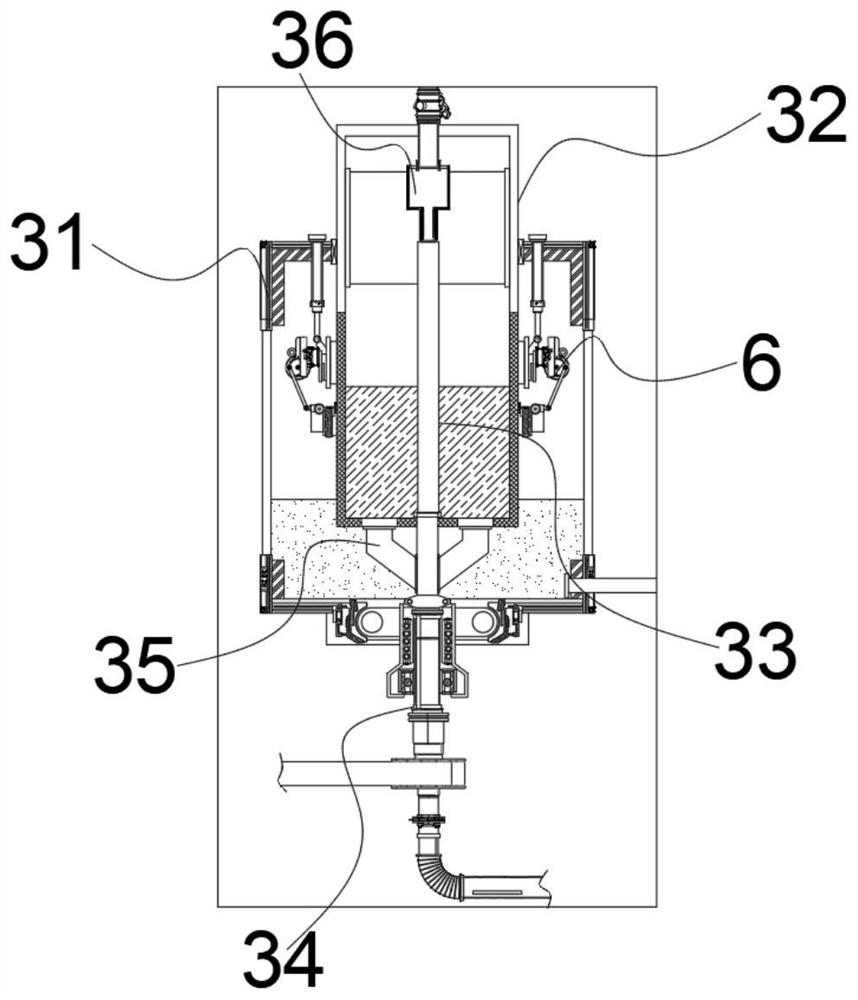

[0063] The side filter component 3 is communicated with the feed primary treatment component 2, and performs secondary filtration on the thick mud turbid liquid filtered in the feed primary treatment component 2, so that the residual thin muddy turbidity in the thick mud turbid solution is mixed. The drilling fluid can seep out; in particular, a small part of the drilling fluid transported in the feed primary t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com