Subway sand layer open cut pit construction method

A construction method and technology of subway sand, which are applied in excavation, infrastructure engineering, construction, etc., can solve the problems of foundation pit safety risks, affect construction progress, and fail to form a bearing layer, so as to ensure stability and pull-out resistance, Good economic benefits and the effect of ensuring safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

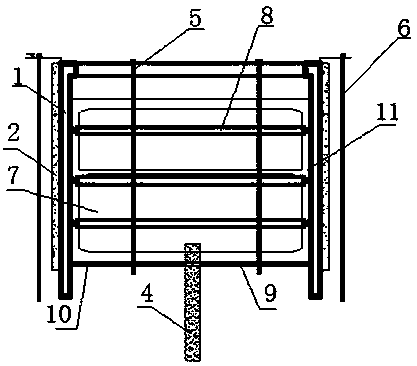

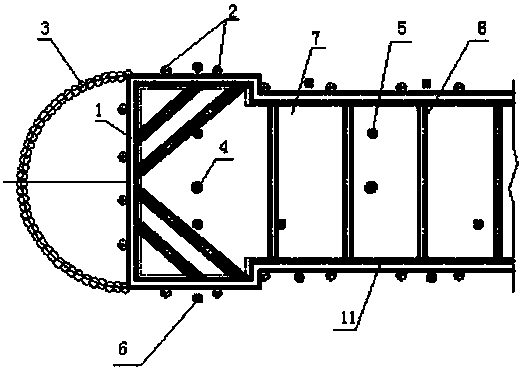

[0028] A method for constructing an open excavation foundation pit in a subway sand layer, specifically comprising the following steps:

[0029] 1) Closed construction of the underground diaphragm wall along the periphery of the foundation pit: After measuring and positioning, excavate the trench for the underground diaphragm wall with a groove forming machine, put the processed steel cage into the excavated groove and pour concrete.

[0030] 2) Construction of dewatering wells in the foundation pit: the tube well point dewatering system is used for pumping and dewatering. The depth of the dewatering well is at the position 2m below the structural floor 11 to ensure that the water surface is lower than the structural floor 11, and blind ditches are excavated around the bottom of the pit. All the water in the ditch flows into the interior of the precipitation well, and then is discharged from the precipitation well.

[0031] 3) Construction of observation well 6 outside the fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com