Fire cover

A fire cover and fire hole technology, which is applied to gas fuel burners, combustion methods, combustion types, etc., can solve the problems of flue gas affecting thermal efficiency, poor flame stabilization effect, etc., reduce flashover phenomenon, and have good practicability , the effect of expanding the horizontal width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

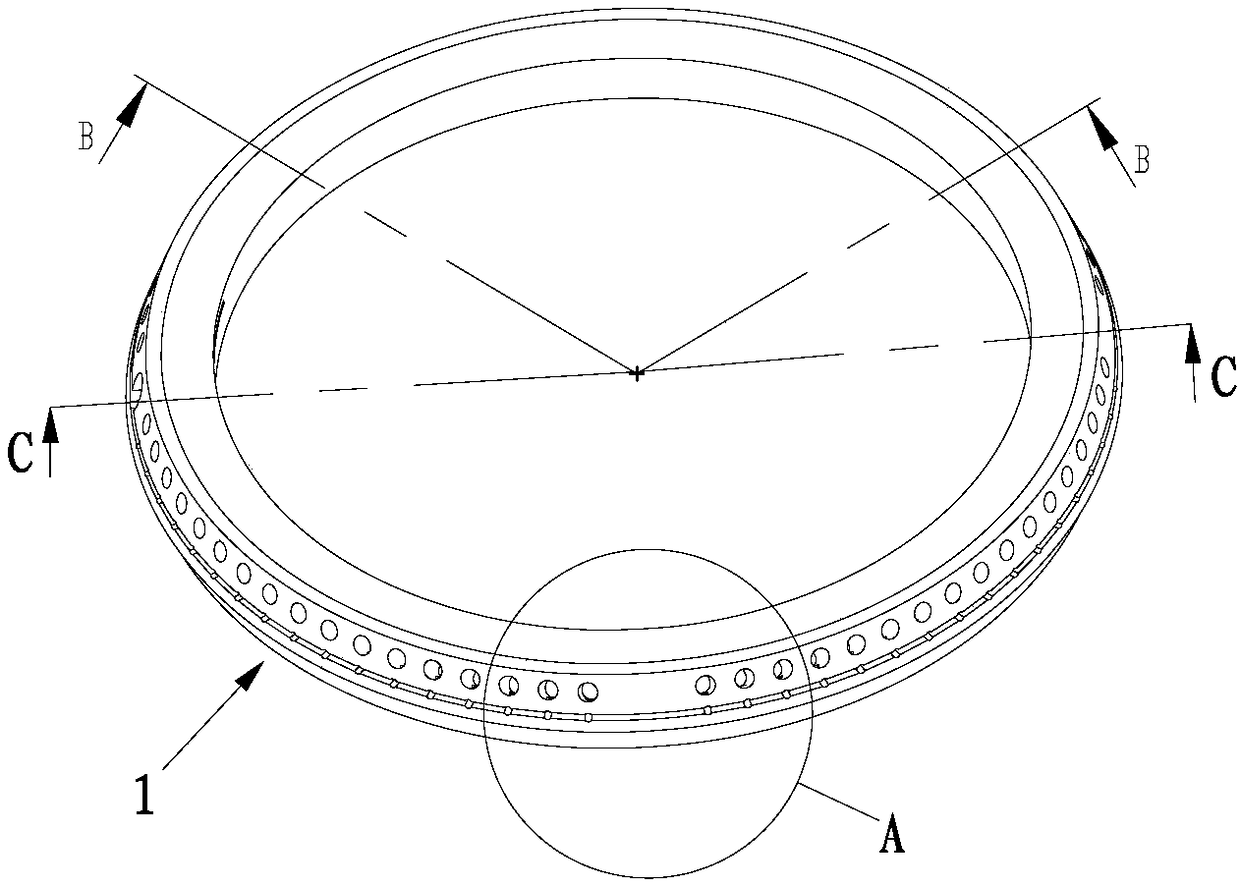

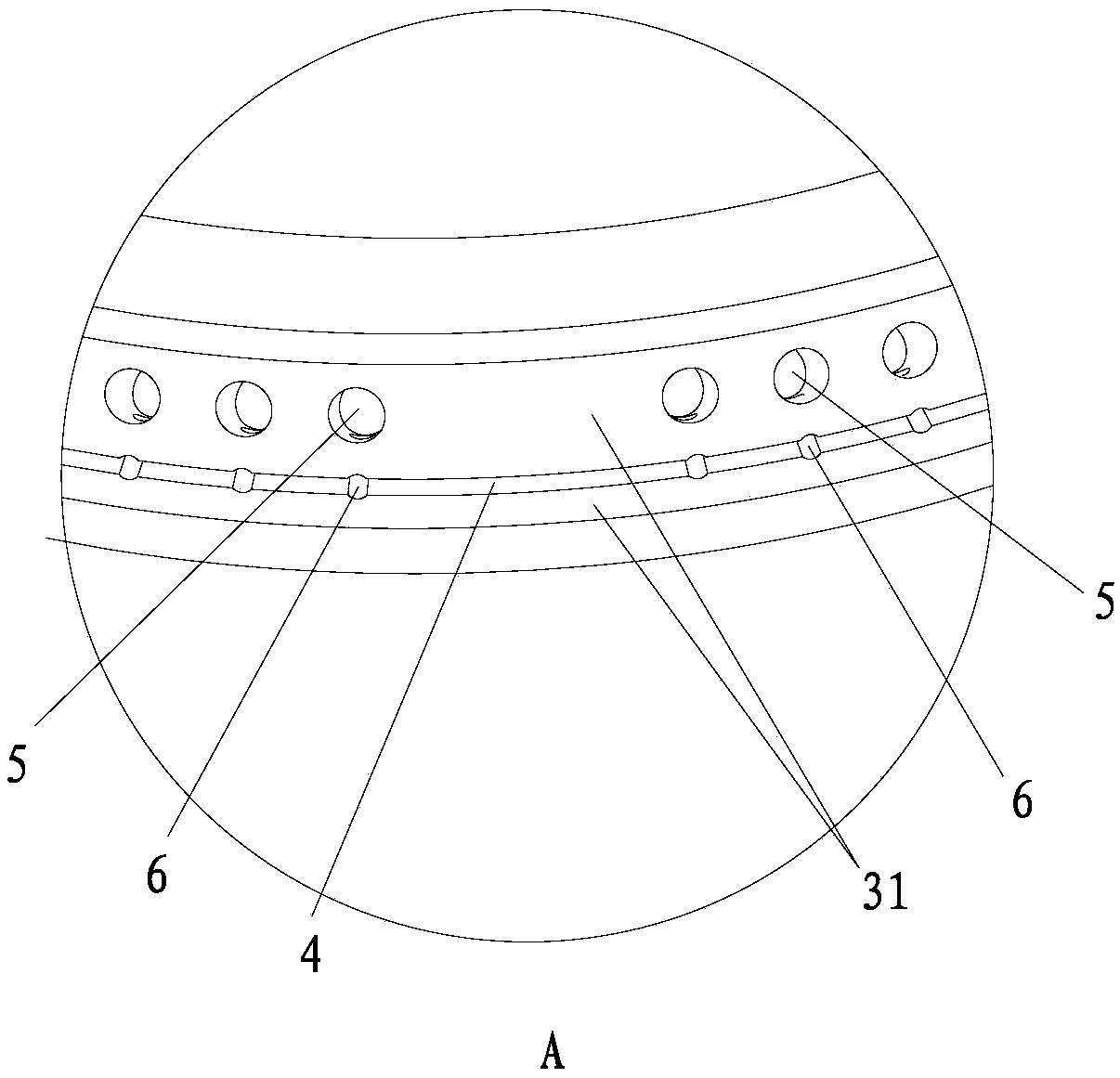

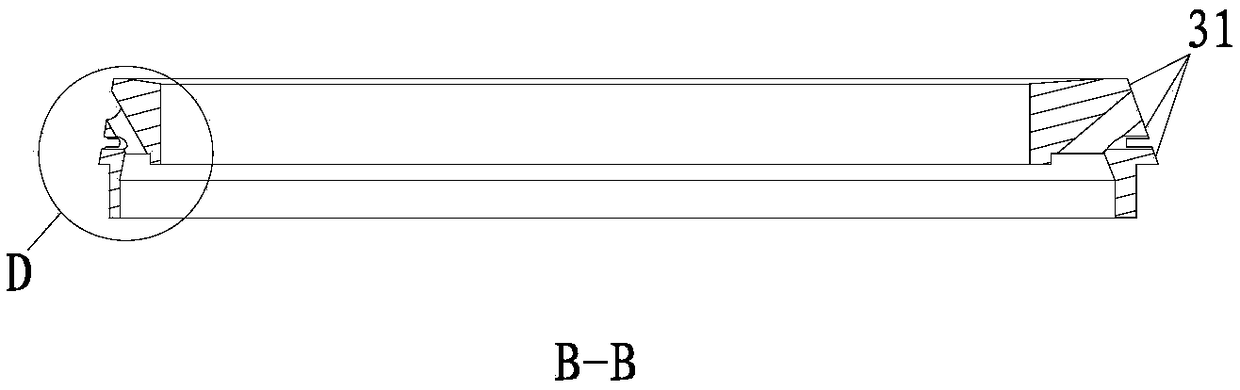

[0046]Example 1, such as Figure 1 to Figure 8 As shown, the main fire hole channel 5 is located on the upper side of the annular groove 4 , and the flame stabilizing fire hole channel 6 is connected to the main fire hole channel 5 by perforating from the annular groove 4 .

[0047] The main fire hole channel 5 gradually extends upwardly from the inside of the gas chamber 2, so that it is convenient to drill holes from the annular groove 4 to communicate with the main fire hole channel 5, so as to form the flame stabilizing hole Channel 6.

Embodiment 2

[0048] Example 2, such as Figure 9 to Figure 16 As shown, the main fire hole passage 5 is located on the lower side of the annular groove 4, and the flame stabilization fire hole passage 6 is connected to the gas chamber 2 by perforating upward from the end of the main fire hole passage 5 close to the gas chamber 2. Ring groove 4.

[0049] The main fire hole channel 5 gradually extends upwardly from the inside of the gas chamber 2, so that the drill bit can be easily inserted into the main fire hole channel 5, and the end close to the gas chamber 2 is drilled upwards to communicate with the annular groove. 4, to form the stable flame hole channel 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com