Rotor assemblies, motors, automobiles

A component and rotor technology, applied in electric components, magnetic circuit rotating parts, electromechanical devices, etc., can solve the problems of blocked permanent magnet heat dissipation, blocking permanent magnet heat dissipation, permanent magnet high temperature demagnetization, etc., to improve output performance and heat dissipation. The effect of improving efficiency and improving heat dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

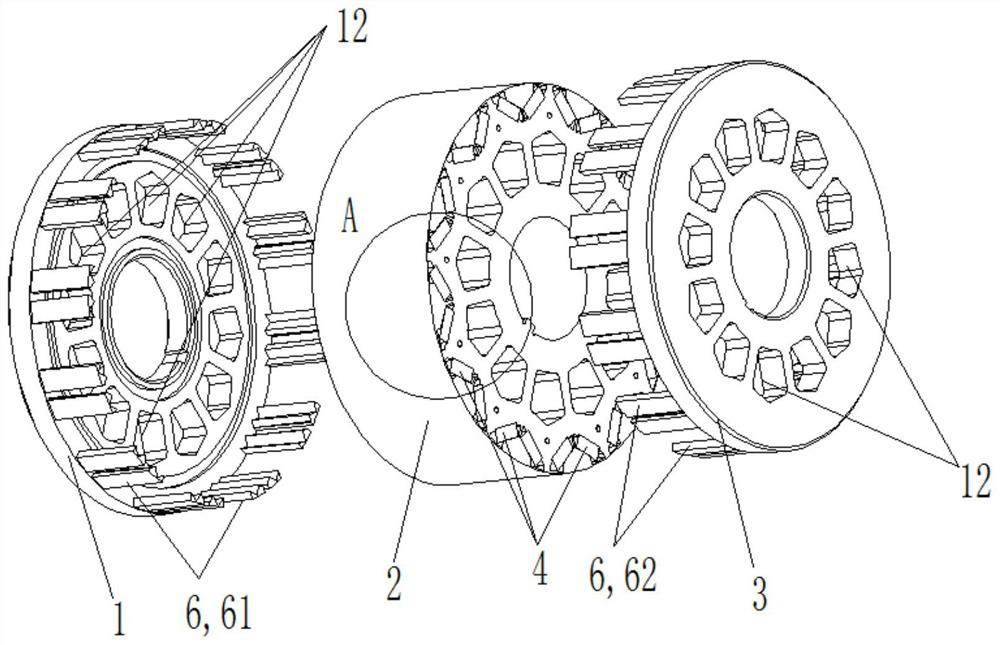

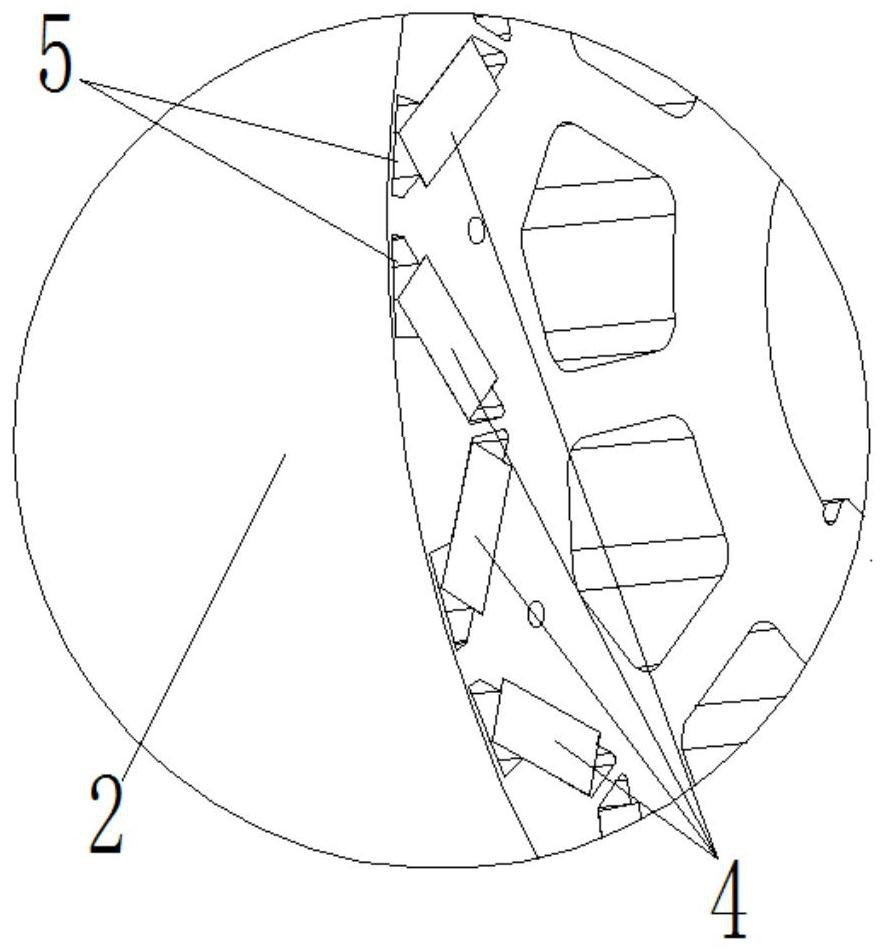

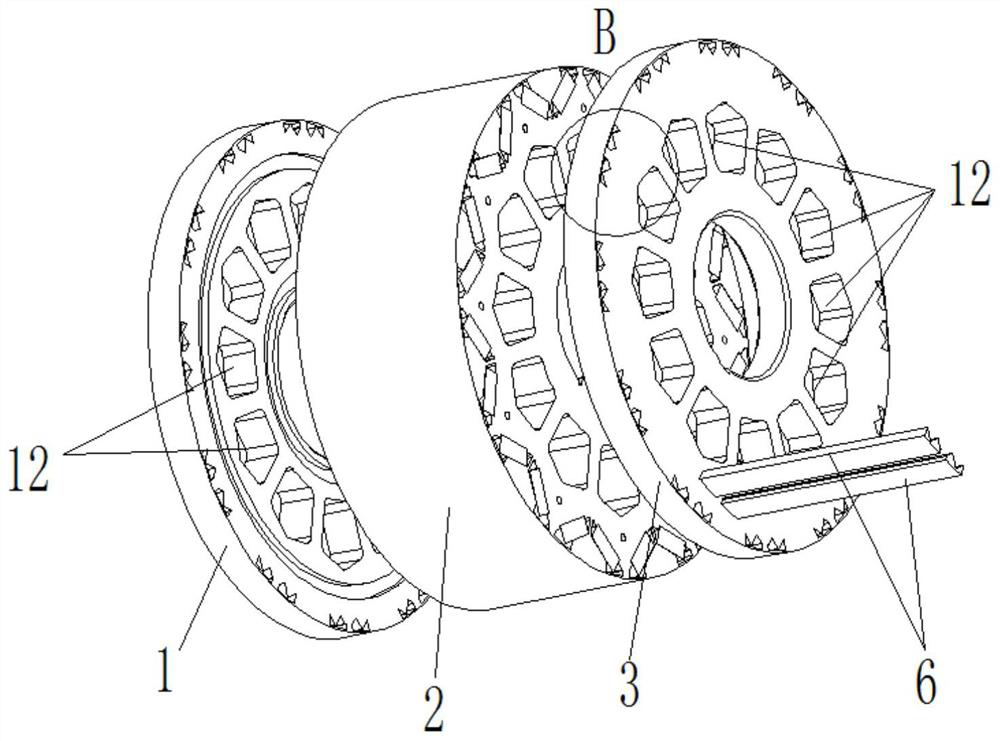

[0023] see in conjunction Figures 1 to 4 As shown, according to the embodiment of the present invention, a rotor assembly is provided, including a first baffle plate 1, a rotor core 2, and a second baffle plate 3 that are sequentially contacted and fitted. The rotor core 2 has a A plurality of extended through slots, a plurality of permanent magnets 4 are inserted in the plurality of through slots, and a plurality of permanent magnets 4 form a plurality of gap slots 5 with the rotor core 2 toward the outer peripheral wall of the rotor core 2, A heat dissipation guide bar 6 is inserted into several of the gap slots 5 , and at least one of the first baffle plate 1 or the second baffle plate 3 is connected to one end of the heat dissipation guide bar 6 . In this technical solution, since the heat dissipation guide bar 6 is inserted into the gap groove 5, at least a part of the heat dissipation guide bar 6 is in contact with the permanent magnet 4, and a part is in contact with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com