Heat dissipation panel with variable-width water channels

A cooling plate and variable width technology, applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve the problems of temperature difference between inlet and outlet, overheating, uneven heat dissipation, etc., and reduce the total pressure drop , uniform temperature distribution, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

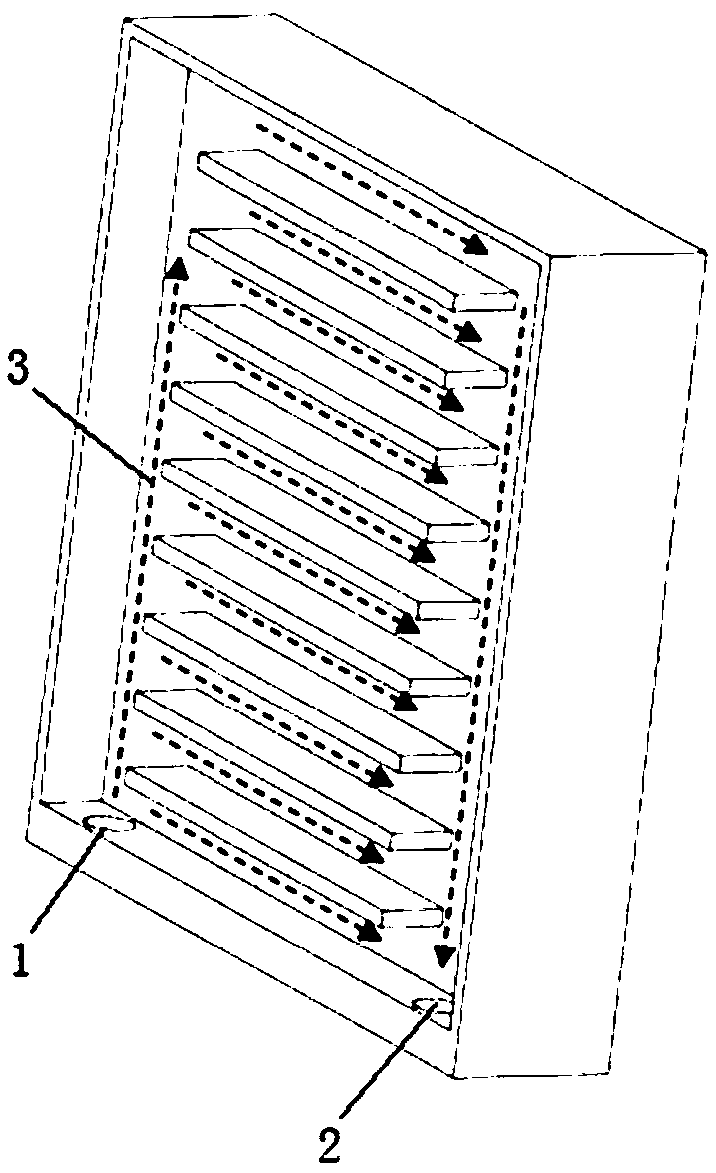

[0022] like figure 1 As shown, the existing radiator plate water channel includes coolant inlet 1, coolant outlet 2 and multiple "S-shaped" serial water channels 3 connected end to end. Due to the long distance of liquid flow, the temperature difference between the inlet and outlet is caused. This results in uneven heat dissipation or localized overheating.

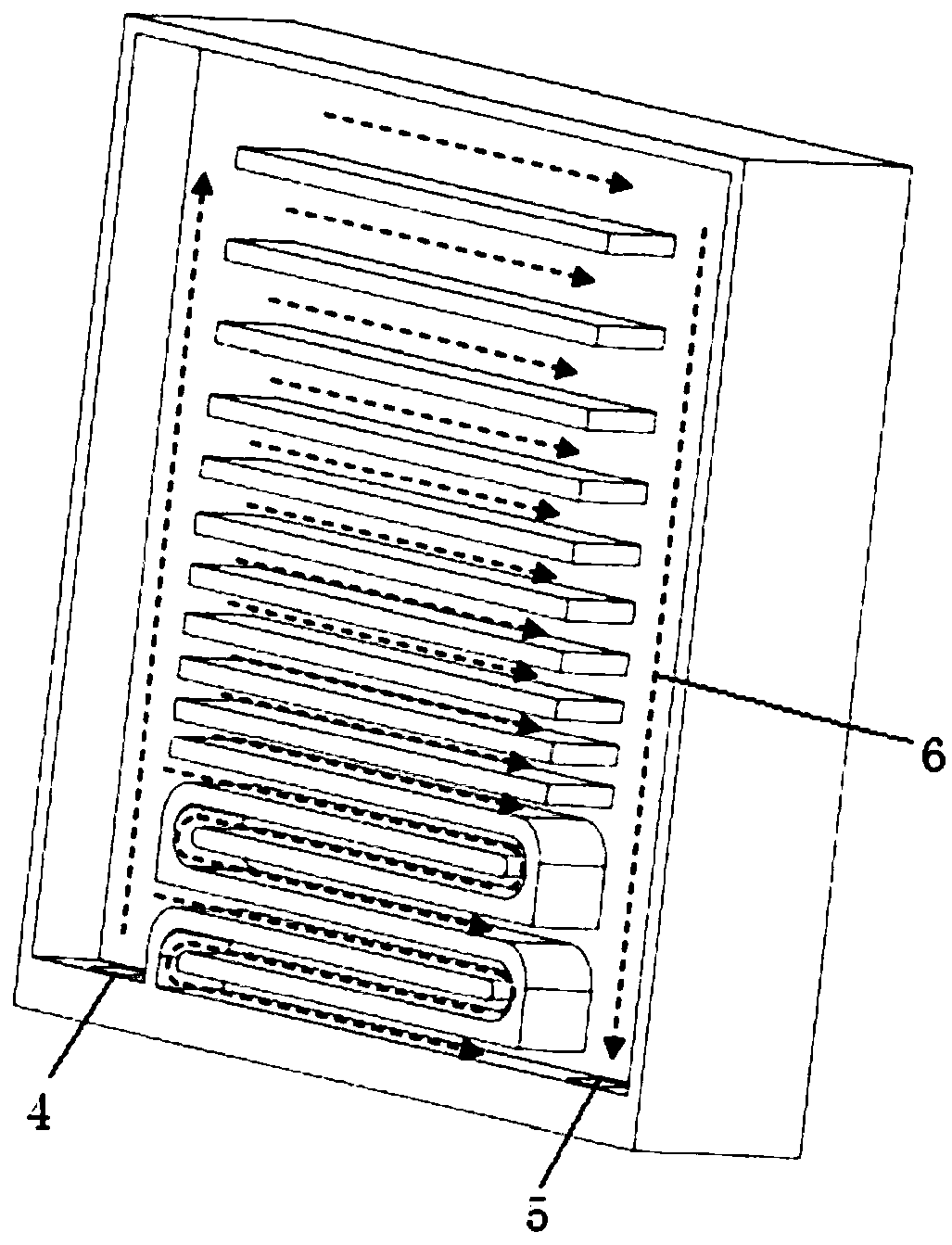

[0023] like figure 2 As shown, a heat dissipation plate of a variable-width water channel of the present invention balances the heat dissipation effect of each water channel by changing the width of the water channel. One or more S-shaped water channels 6 are used on one side of the outlet 5;

[0024] The basic design parameters of the variable width water channel include: total flow, length of cooling plate, width of cooling plate, depth of water channel, width of total inlet and outlet water channel;

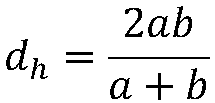

[0025] Pressure drop for parallel channels:

[0026] For laminar flow:

[0027] For turbulent flow:

[002...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap