Cone crusher

A technology of cone crusher and crushing chamber, which is applied in the field of crushing, grinding or crushing equipment, which can solve the problems of material falling, large spacing, uneven material particle size, etc., achieve high uniformity, improve screening effect, and facilitate The effect of subsequent use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below by means of specific embodiments:

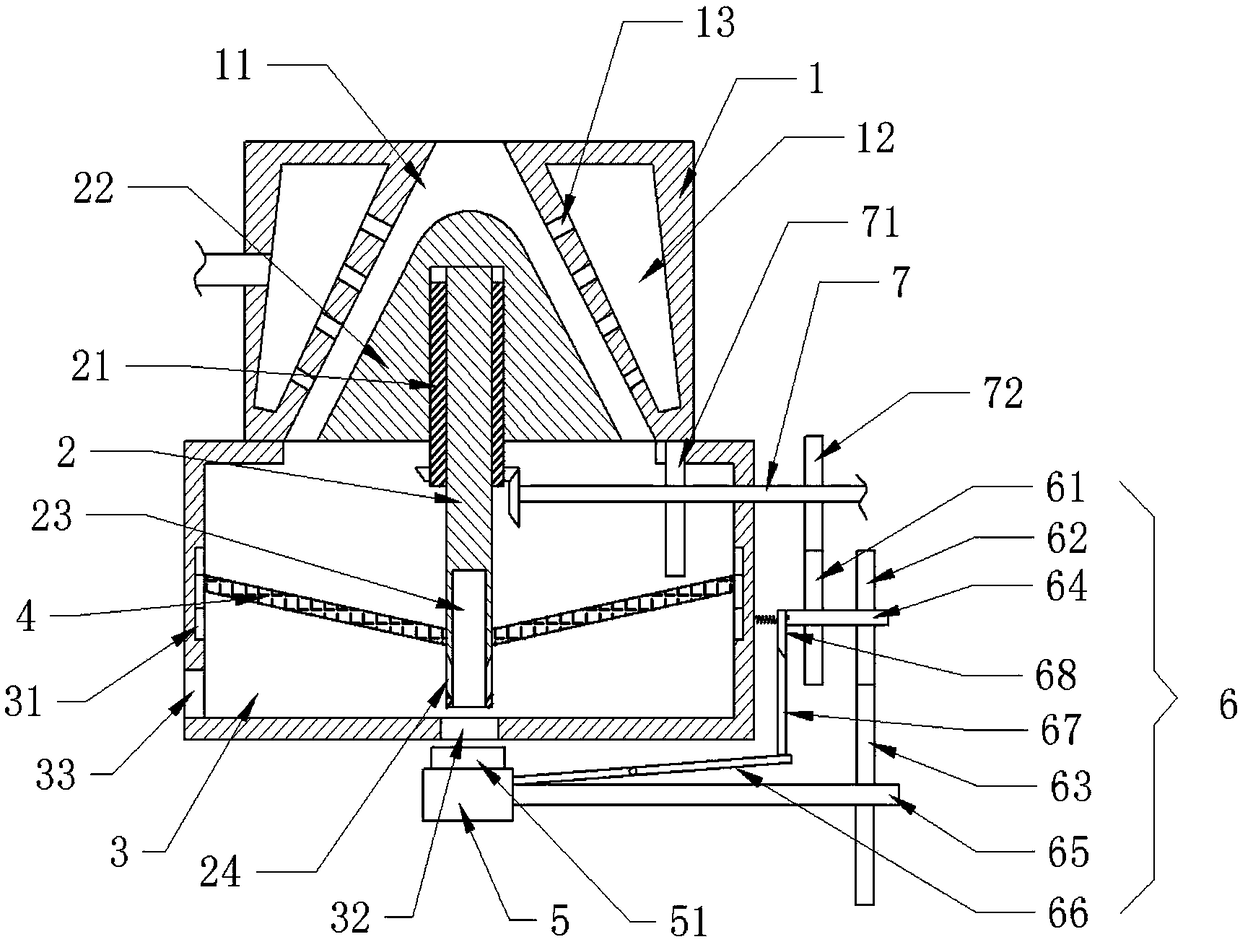

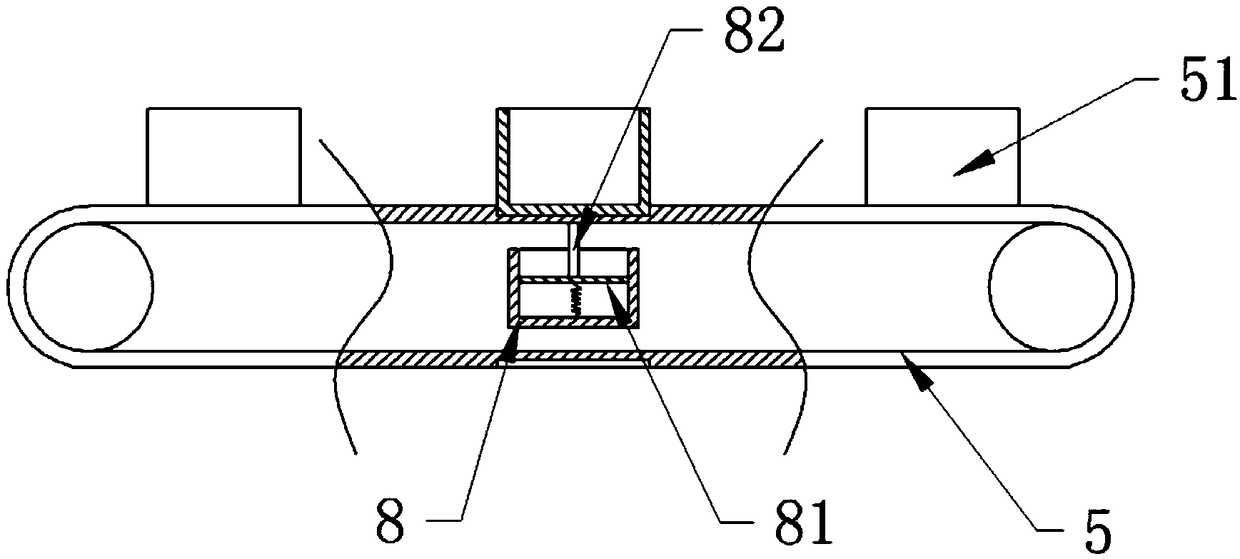

[0034] The reference signs in the accompanying drawings of the specification include: crushing seat 1, crushing chamber 11, air collecting chamber 12, dust removal hole 13, installation shaft 2, eccentric sleeve 21, crushing roller 22, material receiving trough 23, material guide port 24, collecting Box 3, chute 31, discharge port 32, feed port 33, sieve plate 4, conveyor belt 5, transfer box 51, drive mechanism 6, first drive gear 61, second drive gear 62, third drive gear 63, First drive shaft 64, second drive shaft 65, pole 66, first wedge bar 67, second wedge bar 68, rotating shaft 7, cam 71, driving gear 72, gas tank 8, slide plate 81, push rod 82.

[0035] The embodiment is basically as attached figure 1 Shown:

[0036]The cone crusher includes a frame on which a crushing seat 1 is vertically slidably connected, a collection box 3 is provided under the crushing se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com