Lateral discharging type discharging device of ball mill

A ball mill, side-discharge technology, applied in the field of side-discharge ball mill discharge device, can solve the problems of affecting sealing performance, inconvenient processing, material residue, etc., and achieve the effect of ensuring stability and timeliness, avoiding interference and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

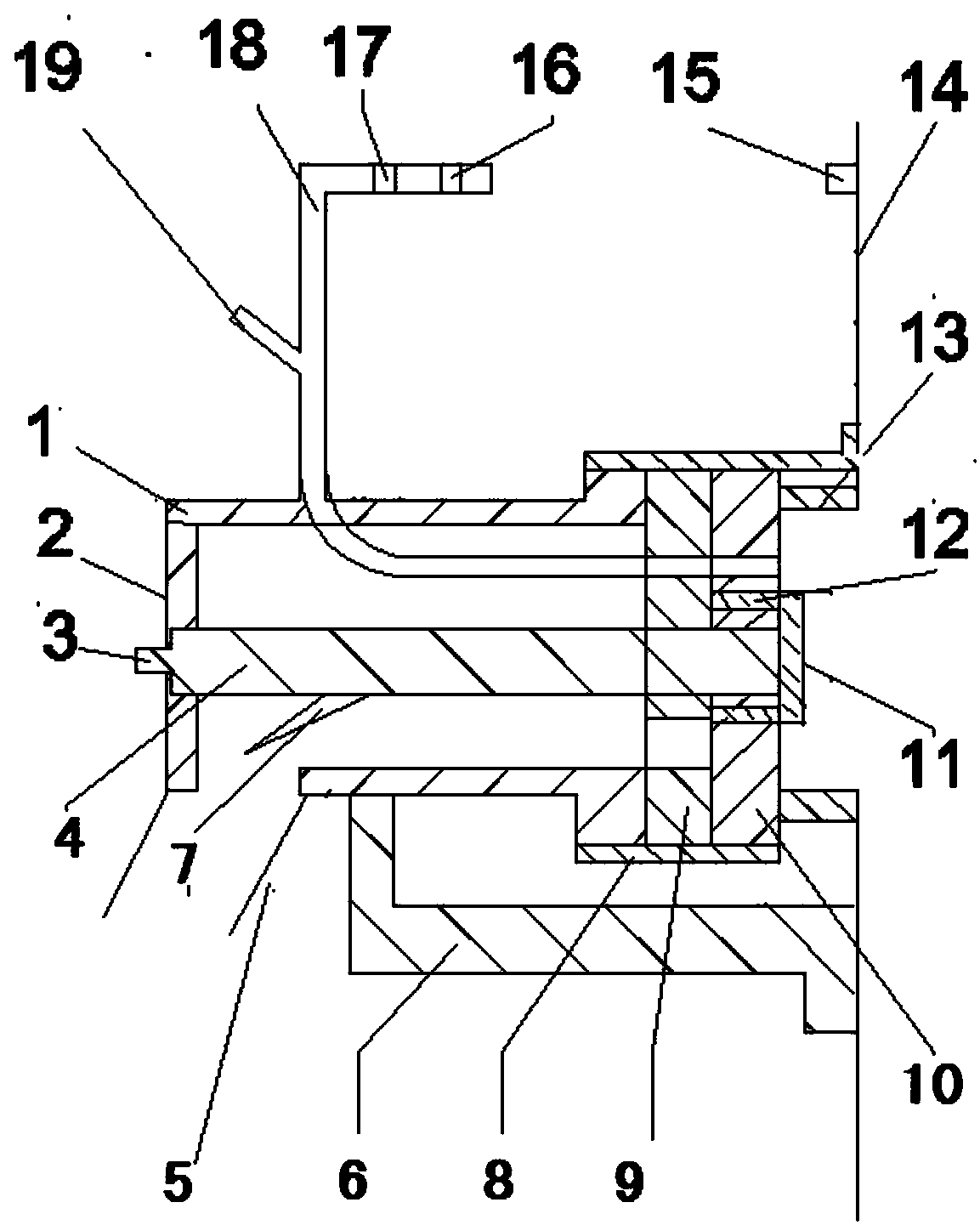

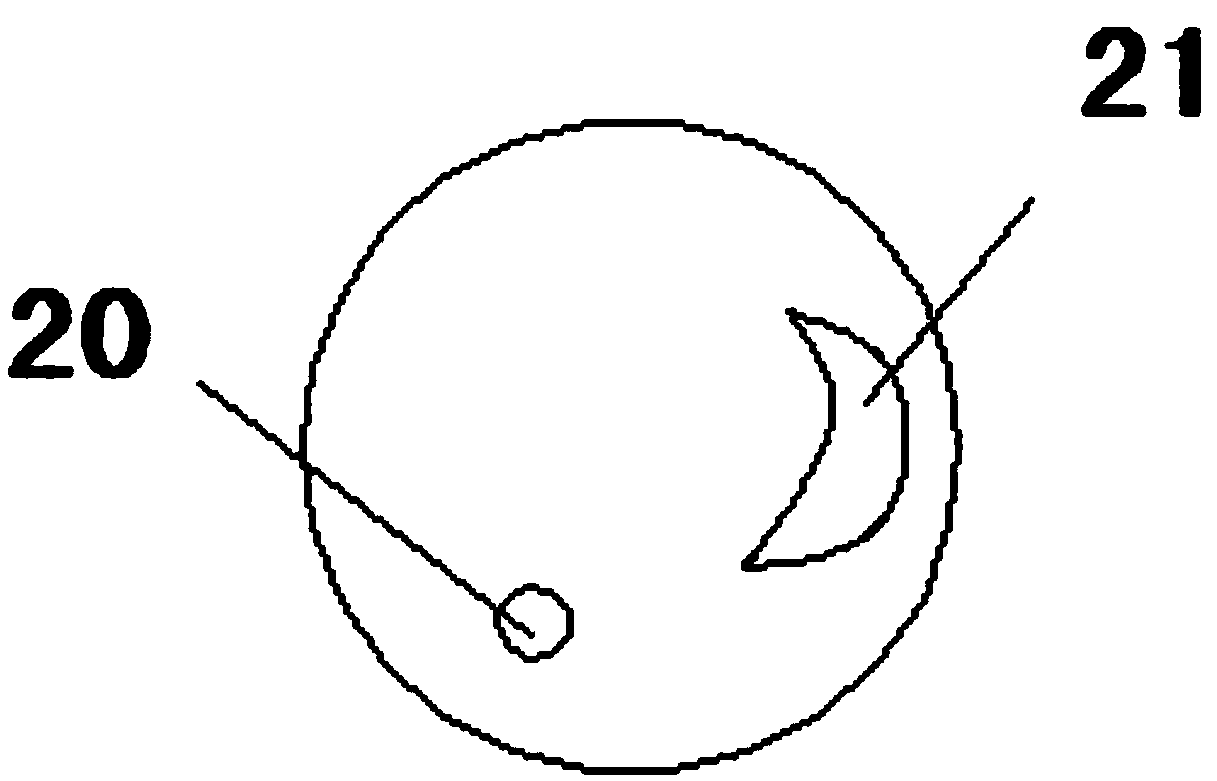

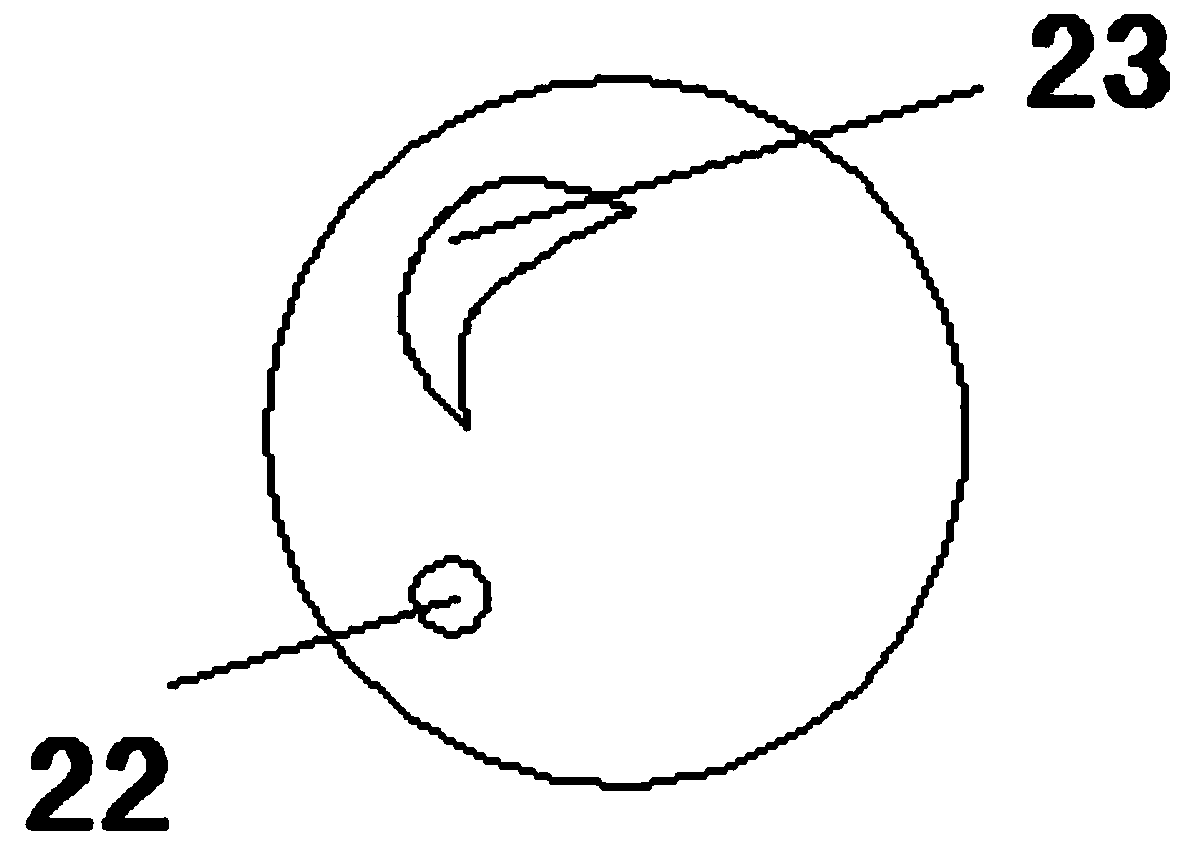

[0034] A discharge device for a side-discharge ball mill, including a valve body, a limit plate, a short column, a valve stem, a discharge pipe, a bracket, a material guide, a segmented screw sleeve, a static valve disc, a movable valve disc, and a limit member , drive column, connectors, ball mill tank, sensor, first stop valve, second stop valve, sampling pipeline, purge pipeline, sampling purge hole 1, discharge hole 1, sampling purge hole 2, exhaust material hole 2, chute, rotating ring, and cut-off ring; the bracket is provided under the valve body, and the right end of the bracket is connected to the tank body of the ball mill; the valve body is arranged on the side of the tank body of the ball mill, and the left end of the valve body is provided The right end of the valve body is provided with a radially extending ring-shaped protrusion, a static valve disc is set on the right side of the protrusion, and a moving valve disc is set on the right side of the static valve di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com