Method and system for spread cooling and stacking during brewing

A technology of wine grains and racks, which is applied in the field of cooling and stacking methods and systems for brewing stalls, and can solve the problems of difficult control of the amount of koji added and stirring uniformity, unfavorable stability of brewing quality, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

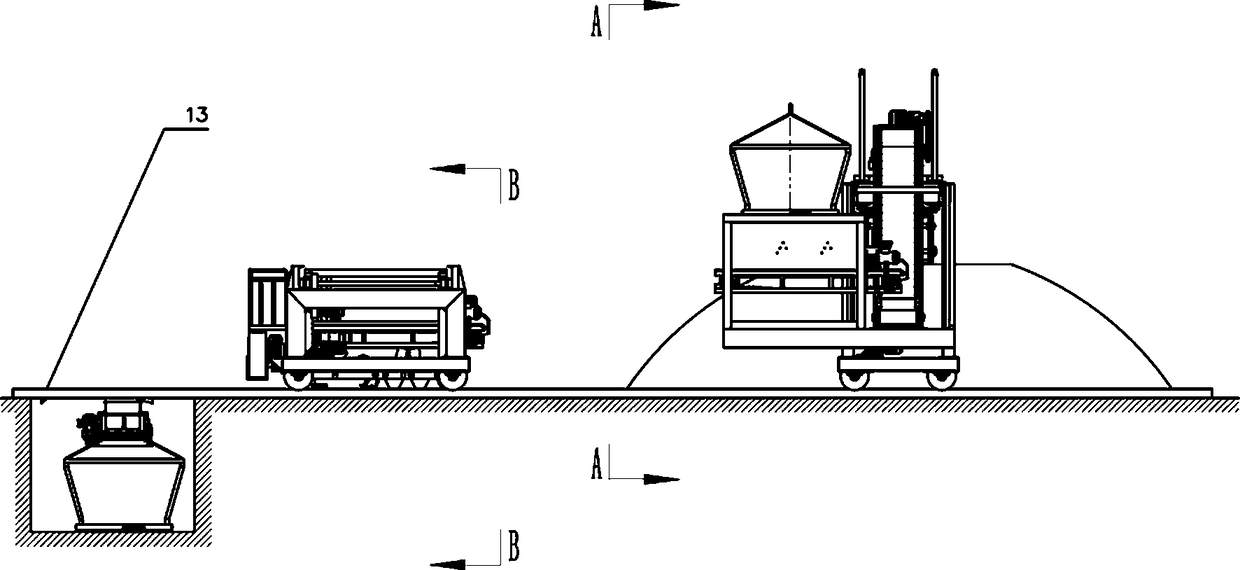

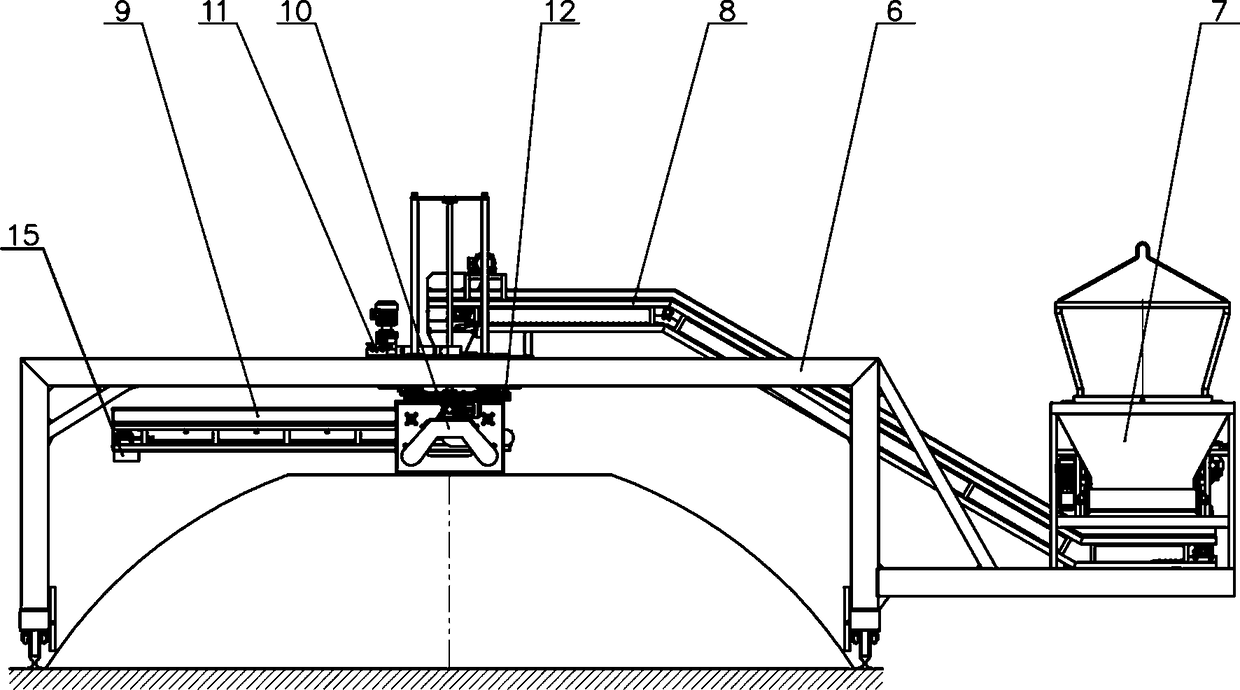

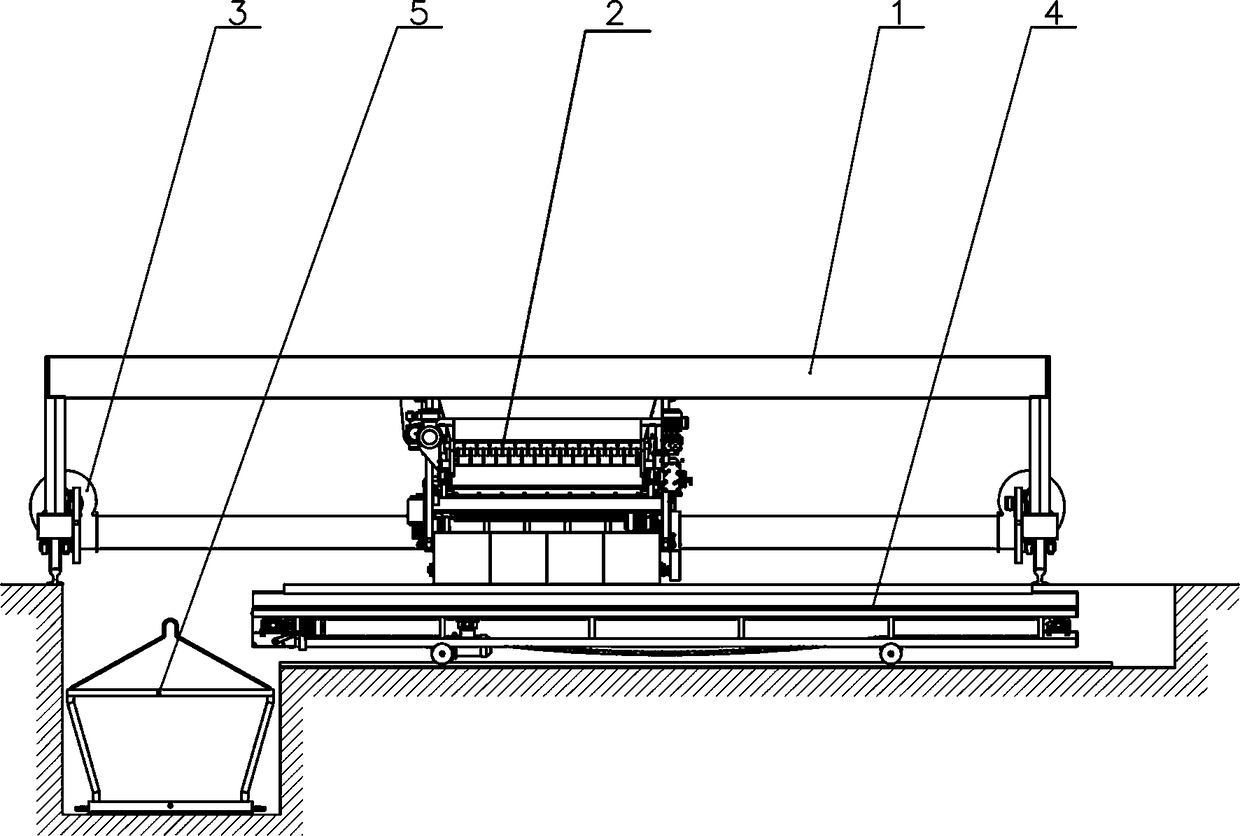

[0033] The embodiments of the present invention will be further described below with reference to the accompanying drawings.

[0034] A method for brewing to cool and pile up, which is characterized in that: the method comprises tiling, cooling, adding koji, and pile-up;

[0035] The tiling is to spread the fermented grains on the ground with a thickness of 10-30CM;

[0036] Described spreading is cool, the wine grains spread on the ground is repeatedly carried out with plow blocks to lift the ridge, so that the temperature of the wine grains is less than 20 degrees;

[0037] Described adding koji, the fermented glutinous rice wine is scattered on the glutinous rice grains of the ridge, and then the glutinous rice glutinous rice ridge is scattered, and the fermented glutinous rice wine is mixed with the fermented rice wine to make a mixture;

[0038] The stacking is carried out by stacking the mixture.

[0039] Preferably, the method further comprises a preprocessing step, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com