Fastener assembly provided with bolts and suitable for heavy-load railway with axle load being 35-40 tons

A bolt buckle and railway technology, which is applied in roads, tracks, buildings, etc., can solve the problems of complicated installation and disassembly, high manufacturing cost, and many fastener parts, so as to achieve convenient maintenance and repair operations, lower construction costs, and fewer parts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

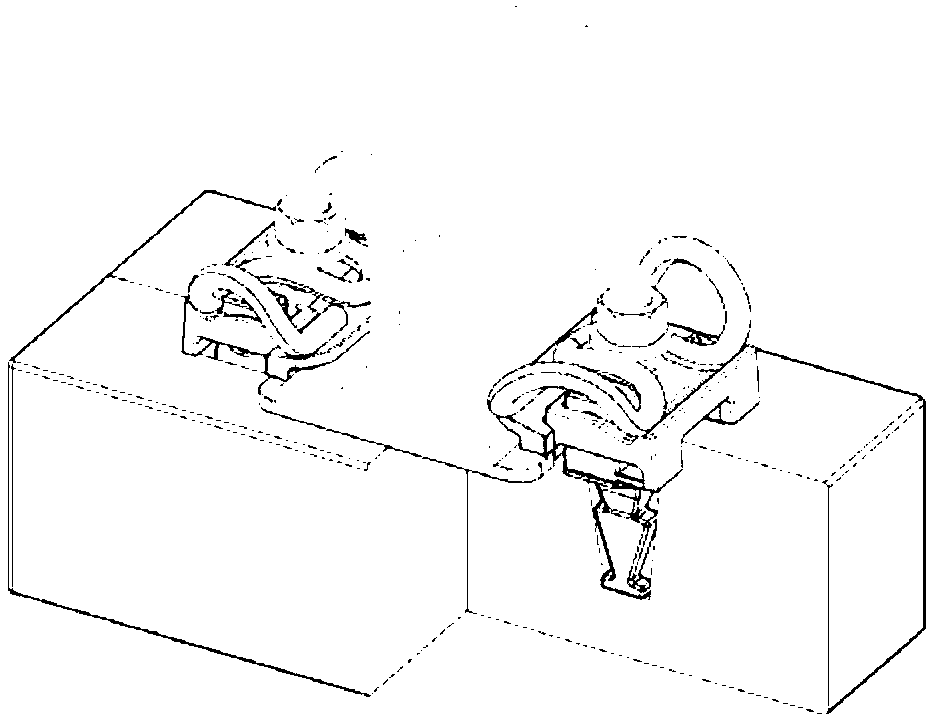

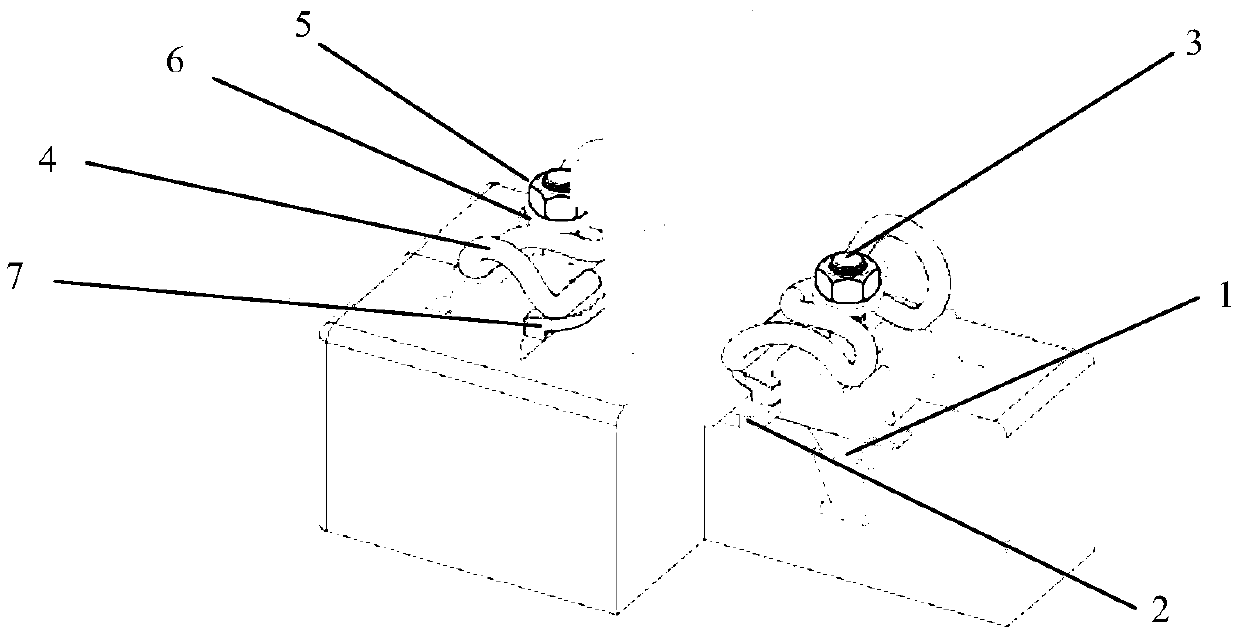

[0020] As shown in the figure: a bolted fastener assembly suitable for heavy-duty railways with an axle load of 35 to 40 tons, consisting of T-shaped bolts 3, nuts 5, flat washers 6, spring bars 4, insulating gauge blocks 7, under-rail The backing plate 2 and the pre-embedded iron seat 1 are composed of the pre-embedded iron seat 1 pre-embedded on the concrete foundation, and a dovetail groove is opened on the pre-embedded iron seat. The elastic strip 4 is fastened and installed, the elastic strip 4 extends into the elastic strip receiving groove 9 of the embedded iron seat 1, and the insulating gauge block 7 is set between the rail and the embedded iron seat 1, and at the same time, the insulating gauge of different thickness is replaced Block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com