Rotary hearth furnace support carrier roller platform-free installation and adjustment method

A support roller, installation and adjustment technology, applied in the direction of measuring devices, instruments, surveying and navigation, etc., can solve the problems of pipeline installation schedule conflict, extension of construction period, waste of resources, etc., to reduce construction costs, increase construction period, and improve construction efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

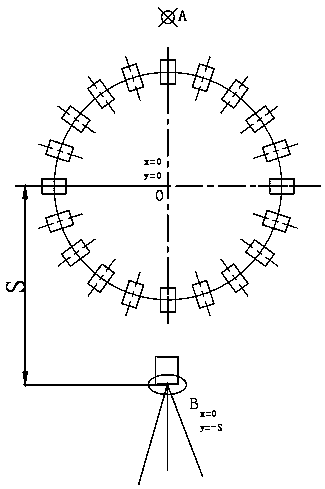

[0016] like figure 1 Shown: The platform-free installation and adjustment method of the supporting roller of the rotary hearth furnace includes the following steps:

[0017] Step 1, hoist all idlers in place, and initially install them in place;

[0018] Step 2, determine a pre-embedded point A on the zero-degree line of the design position, as the 0-degree backsight point of the total station;

[0019] Step 3: After the preliminary installation of the rotary hearth furnace equipment is completed, determine the position of the center O of the rotary hearth furnace, and set this point as the origin O (0, 0) of the plane Cartesian coordinate system;

[0020] Step 4. Set up the total station at point B outside the circle where the roller is located, and the three points O, A, and B are on a straight line, that is, coincident with the zero-degree line of the designed circle. Use the total station and the reflector for measurement Prism, measure the distance of BO, set it as S, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com