Damage mechanics-based high-strength metal material amplitude variation ultra-high cycle fatigue life predication method

A technology for fatigue life prediction and metal materials, applied in the direction of testing material strength by applying repetitive force/pulsation force, testing material strength by applying stable tension/compression, and analyzing materials. It can solve problems that are difficult to apply, lack of theoretical foundation, Inapplicable and other problems, to achieve the effect of clear thinking, simple and fast calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Taking TA15 titanium alloy as an example, the specific steps of the variable-amplitude ultra-high cycle fatigue life prediction method based on damage mechanics are as follows:

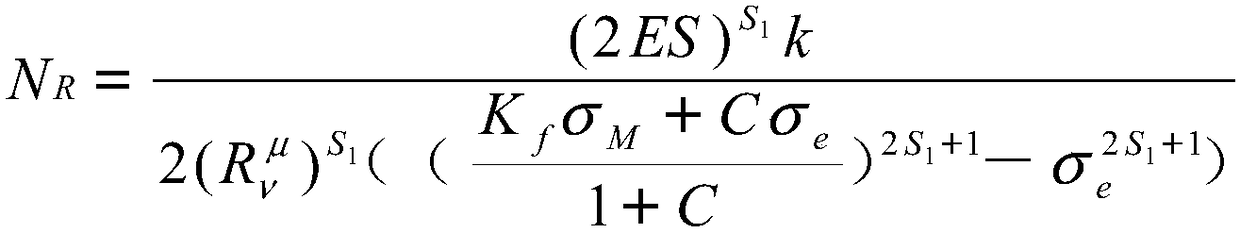

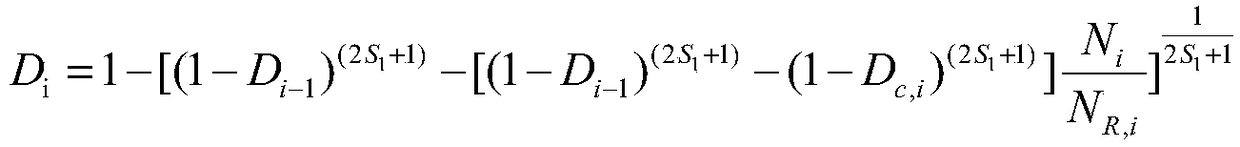

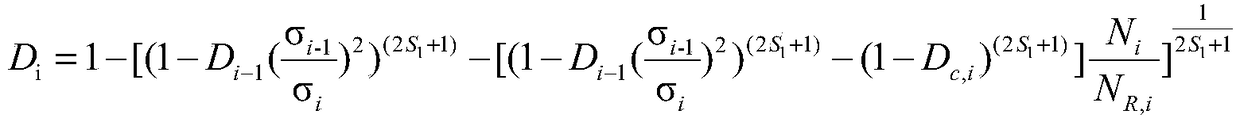

[0031] (1) Design and process high-strength metal material ultrasonic fatigue smooth specimen, marked as specimen 1, conduct ultra-high cycle fatigue test on specimen 1 by ultrasonic fatigue method, test frequency 20kHz, obtain material fatigue strength-life data, and draw material Fatigue S-N curve, obtain parameters S=130 and S 1 =3, where S is the material fatigue damage strength, S 1 is a nonlinear cumulative parameter;

[0032] (2) Perform a tensile test on specimen 1 with a loading rate of 0.0002s -1 , draw the tensile curve of specimen 1, and according to the tensile curve, the elastic modulus E=110GPa, hardening coefficient k=1634, material parameter C=0.6E / k=40.4, tensile strength σ b =367MPa;

[0033] (3) Then carry out metallographic treatment on specimen 1, select the primary α ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com