A Step-by-Step Hot Isostatic Pressing Preparation Method of High-performance Powder Metallurgy Titanium Alloy

A technology of powder metallurgy and hot isostatic pressing, which is applied in the field of metal material processing and preparation, can solve the problems of reducing the room temperature elongation and high cycle fatigue strength of the alloy, and cannot be completely broken, so as to ensure the shape and size accuracy and avoid plastic loss. The effect of stabilizing and avoiding deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

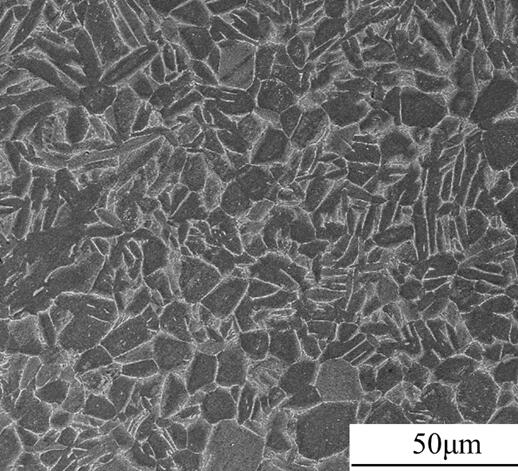

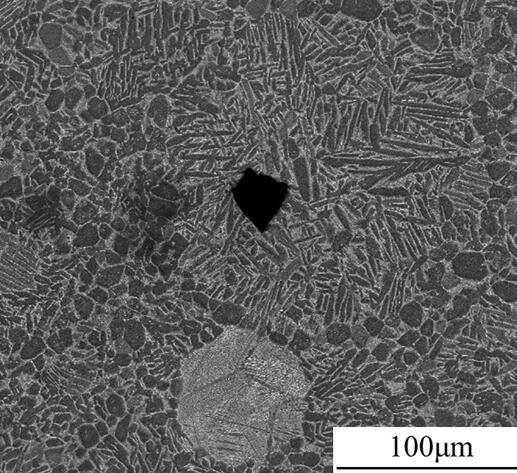

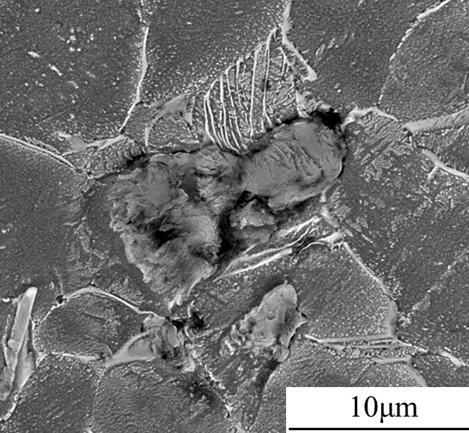

[0036] The specific implementation manner of the present invention will be further described below in conjunction with specific implementation examples and accompanying drawings.

[0037] Comparative Example (Adopting Traditional Simultaneous Heating and Pressurization Hot Isostatic Pressing Process)

[0038] This comparative example uses high-temperature titanium alloy (Chinese brand TA32) powder, and its alloy composition is: Al 5.5%, Sn3.5%, Zr 3.0%, Mo 0.7%, Si 0.3%, Nb 0.4%, Ta 0.4%, more than The amount is Ti.

[0039] Simultaneous temperature rise and pressure hot isostatic pressing process: the TA32 titanium alloy powder prepared by the gas atomization method is sieved, and the particle size is 5-250 μm.

[0040] Fill the TA32 titanium alloy powder into the low carbon steel cylindrical sheath. The outer diameter of the jacket is 120mm, the height is 90mm, and the wall thickness is 3mm. Filling by impact vibration and volume deduction method, the filling relative den...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com