Combined cable structure

A cable structure and combined technology, applied in the field of combined cable structure, can solve the problems of poor heat dissipation performance, reduced cable service life, increased area usage, etc., to increase shear resistance, increase heat dissipation effect, and increase heat dissipation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

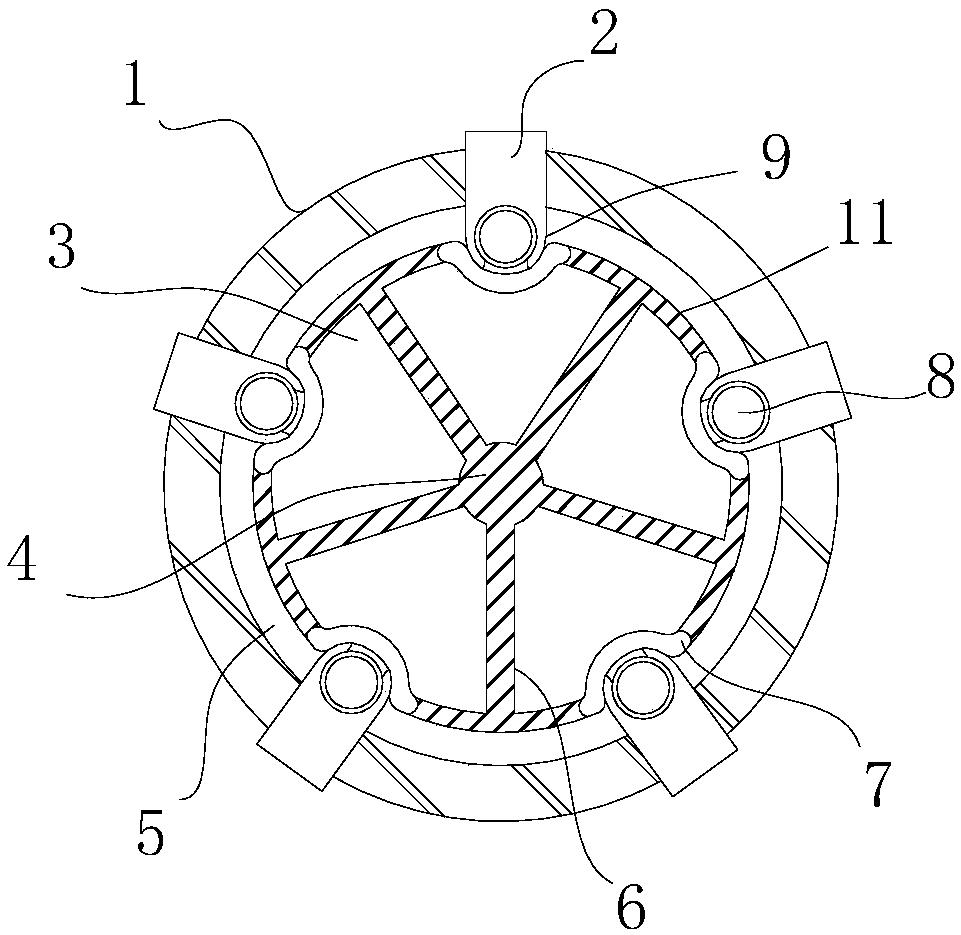

[0022] Such as figure 1 As shown, the combined cable structure includes a cable sheath layer 1, an installation cavity 5 is formed in the middle of the cable sheath layer 1, and more than one fixing clip is clamped on the outside of the cable sheath layer 1, and the fixing clips are evenly distributed and clamped. On the outside of the cable jacket layer 1, the inner end of the fixing clip extends into the installation cavity 5, and a cable core 8 is installed on the inner end of the fixing clip, and the outside of the cable core 8 is wrapped with an independent protective layer;

[0023] In the middle installation cavity of the cable jacket layer 1, a water delivery pipe 11 is installed for positioning and supporting by each fixing clip. An elastic rubber layer 7 is arranged on the water delivery pipe 11 facing the cable core, and one end of the fixing clip Extruded into the elastic rubber layer.

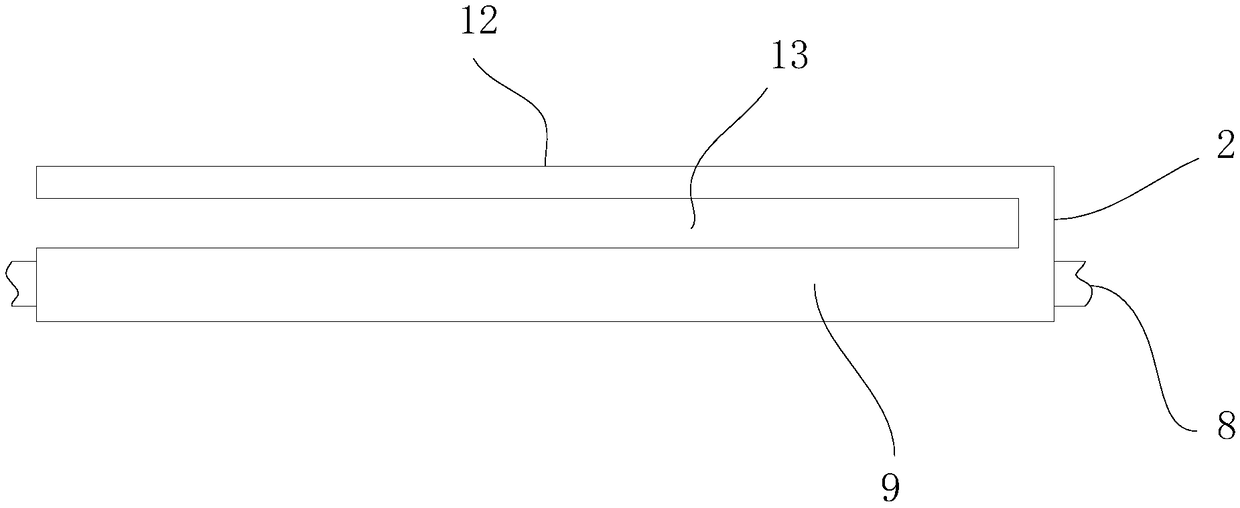

[0024] Such as figure 2 As shown, the fixing clip includes a metal protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com