A method for auxiliary serial connection of double-hole octagonal crystal beads with automatic feeding

A technology of automatic feeding and crystal beads, applied in jewelry, clothing, applications, etc., can solve the problems of low production efficiency of crystal beads in series, achieve the effect of realizing automatic series and improving series efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with accompanying drawing.

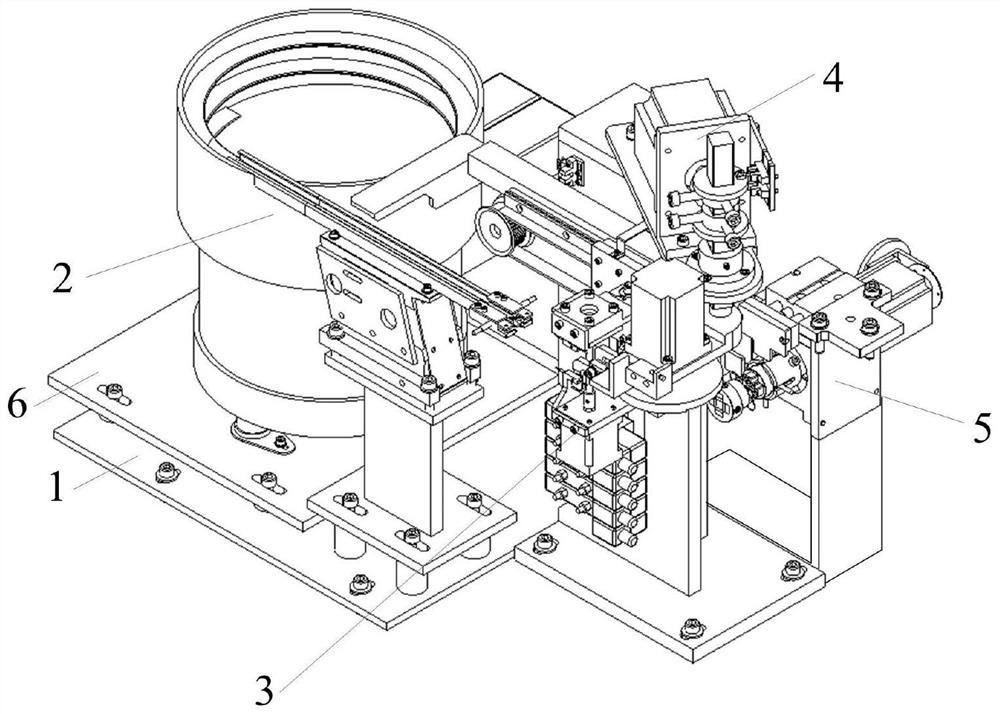

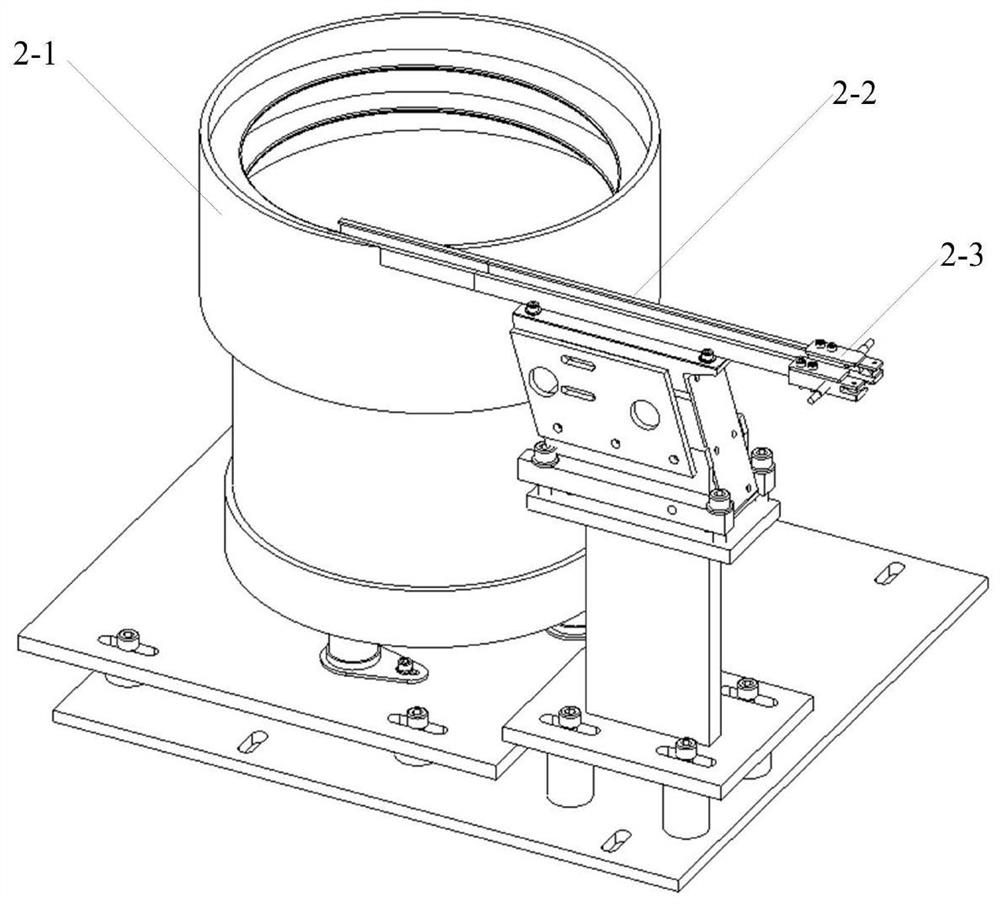

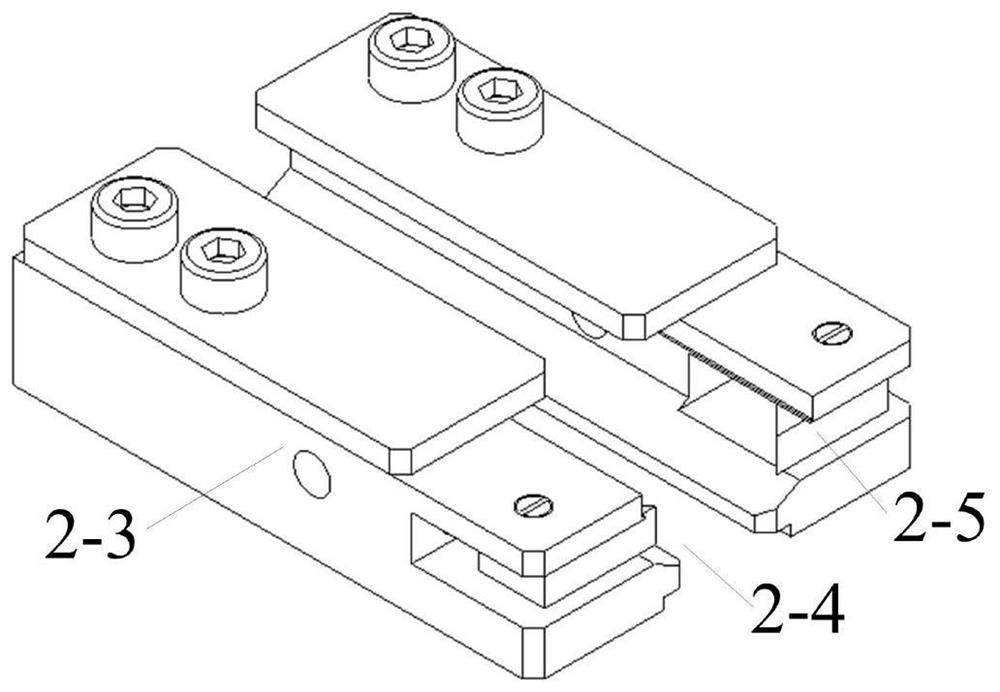

[0051] Such as figure 1 , 2 As shown in and 3, a double-hole octagonal crystal bead auxiliary series connection method for automatic feeding, the series connection fixture adopted includes a bottom plate 1, a vibrating plate discharge mechanism 2, a rotary material transfer mechanism 3, a material transfer mechanical arm 4, four Station clamping mechanism 5 and vibrating plate mounting plate 6. The vibrating plate mounting plate 6 is spaced apart from the bottom plate 1 and fixed by connecting columns. The vibrating plate discharging mechanism 2 comprises a vibrating plate 2-1, a direct vibrator, a conveying rail 2-2, a discharging block 2-3, a material retaining block 2-5 and a material retaining spring. A plurality of double-hole crystal octagonal beads to be threaded are placed in the vibrating plate 2-1. The vibration plate 2-1 is fixed on the vibration plate mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com