A kind of preparation method of fine-grained coal flotation collector

A collector and fine-grained coal technology, applied in flotation, solid separation, etc., can solve problems such as poor recovery effect

Active Publication Date: 2019-10-01

CHINA UNIV OF MINING & TECH

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a fine-grained coal flotation collector preparation method to solve the problem of poor recovery effect of non-polar hydrocarbon oil in coal slime flotation recovery clean coal flotation recovery

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

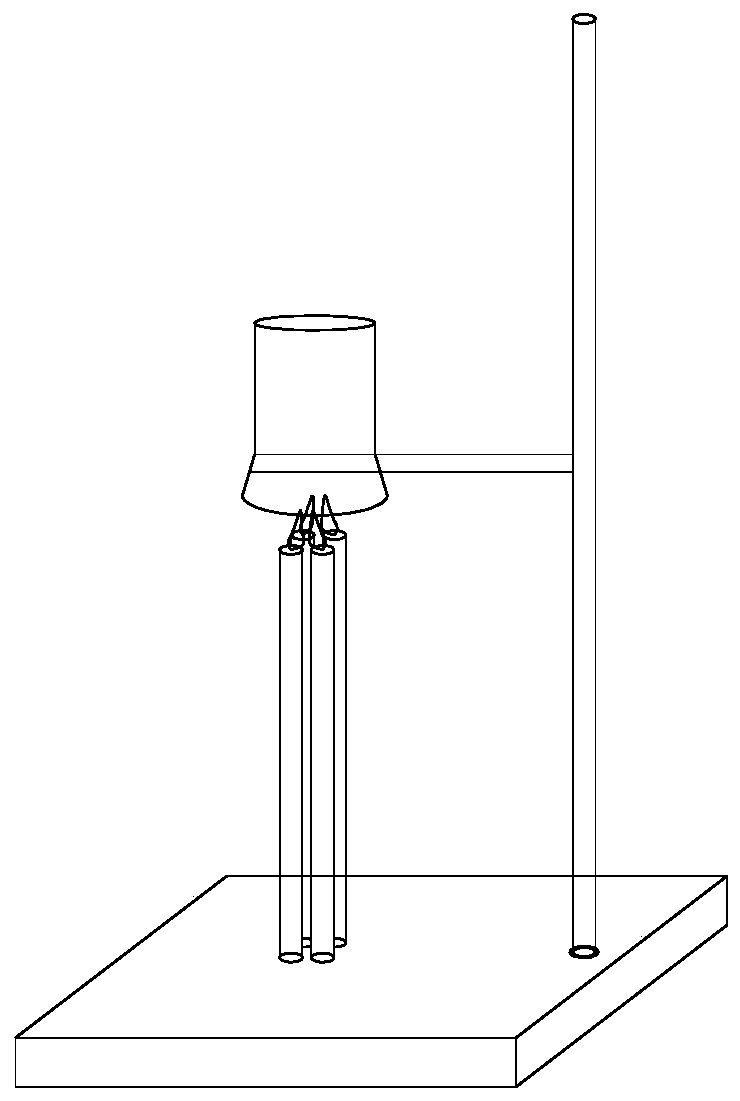

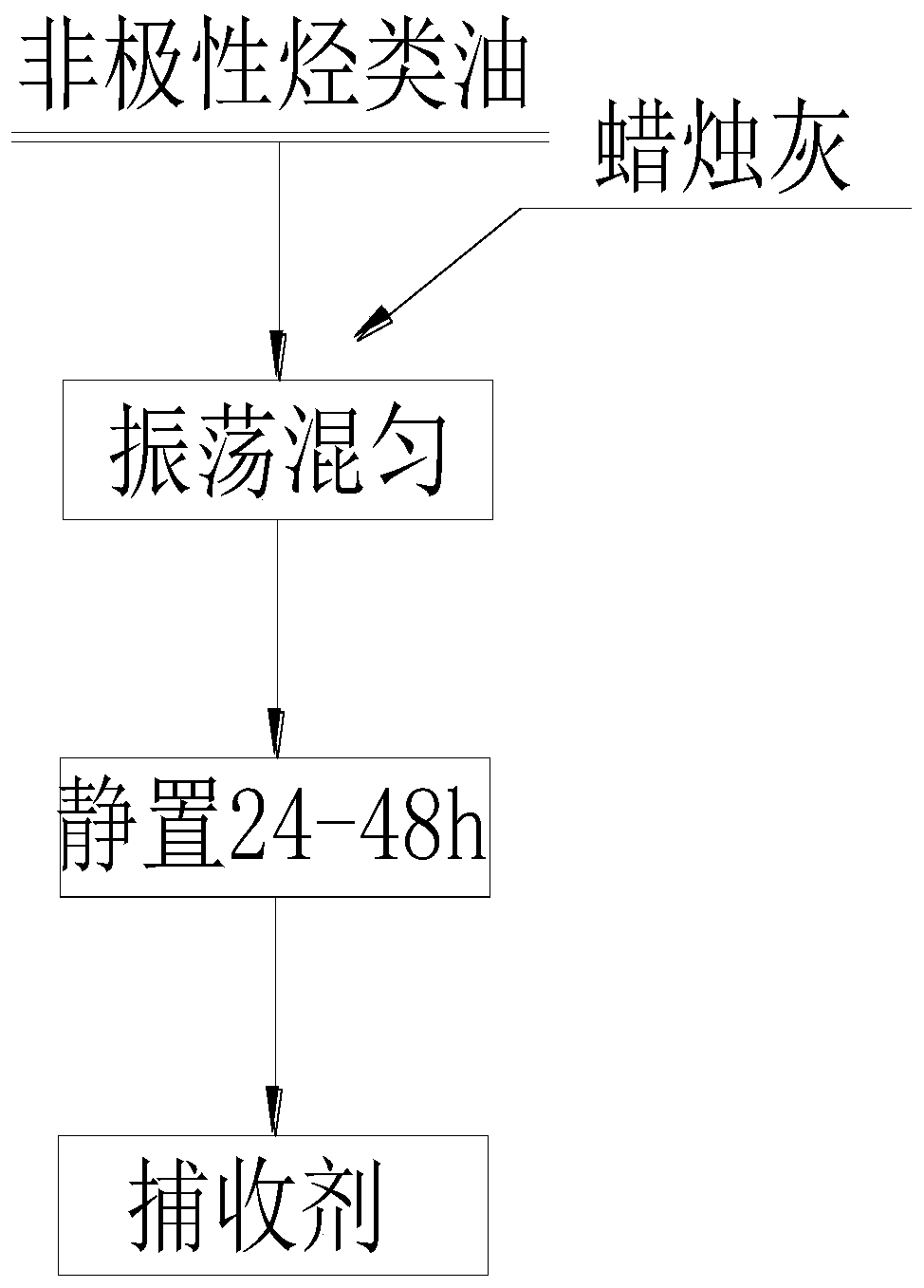

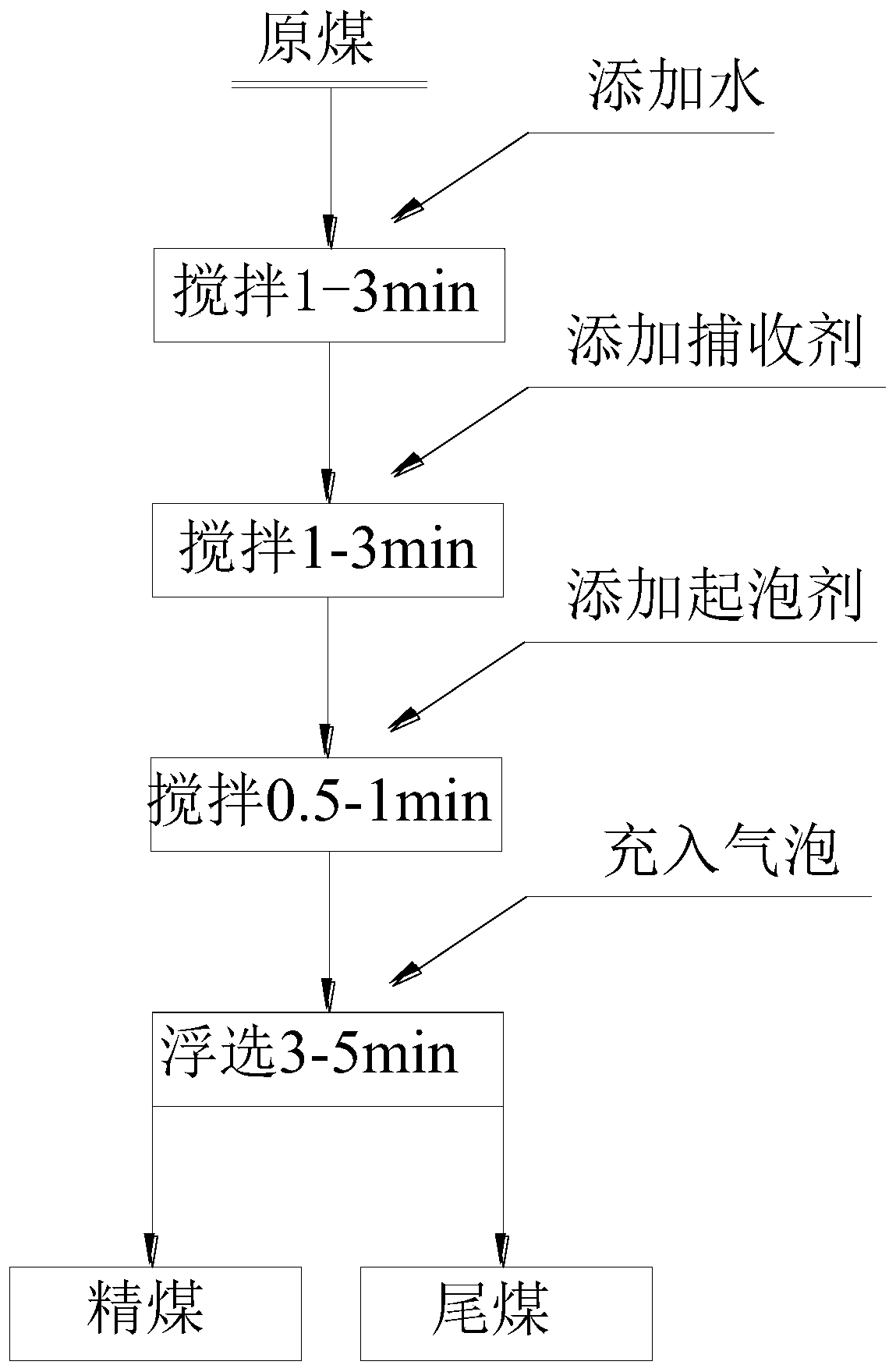

The invention relates to a preparation method of a fine-grained coal flotation collecting agent, and belongs to the technical field of coal flotation reagents. The preparation method of the flotationcollecting agent comprises the following steps that (1) candle ash is prepared, wherein a 250 ml beaker is inverted at the tops of four candle flames so as to enable the flames to be incompletely combusted, the soot is attached to the inner wall of the beaker until a layer of candle ash is formed in the inner wall of the beaker, then the preparation is completed, and the candle ash is collected for later use; and (2) 1 g of the candle ash prepared in the step (1) is taken and added into 120-180 ml of non-polar hydrocarbon oil for uniform mixing, then standing is carried out one the mixture for24-48 hours, and the floatation collecting agent is obtained. According to the preparation method, the candle ash prepared through incomplete combustion of the candle is added into the non-polar hydrocarbon oil, so that the fracture of a hydration film on the surface of mineral and the dispersion of oil drops are facilitated in the flotation process, and then the flotation recovery effect of coalslime is obviously improved. The preparation method has the advantages that compared with a traditional non-polar hydrocarbon oil collecting agent, the non-polar hydrocarbon oil collecting agent contributes to the fracture of the hydration film on the surface of the mineral and the dispersion of the oil drops in the flotation process, so that the hydrophobicity of coal particles is improved, andthe flotation recovery effect of the coal slime is obviously improved.

Description

technical field The invention relates to the technical field of coal flotation agents, in particular to a method for preparing fine coal flotation collectors. Background technique Coal is the most important fossil energy in my country, and its dominant position in the primary energy consumption structure will not change for a long time in the future. Coal is a mixture of organic and inorganic materials and therefore needs to be sorted before use. With the rapid development of the national economy, the demand for energy continues to increase, and coals with medium and high metamorphic degrees are mined in large quantities, and their reserves are decreasing day by day. Not well utilized. High-efficiency coal sorting technology is an important prerequisite for realizing clean and efficient utilization of coal resources. Among them, flotation is currently the most mature and effective method for sorting coal smaller than 0.5mm, and is widely used in industrial production. I...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B03D1/018B03D101/02B03D103/08

Inventor 夏文成李懿江谢广元彭耀丽沙杰倪超梁龙

Owner CHINA UNIV OF MINING & TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com