Preparation method of skin-friendly moisture-holding anti-back-absorption facial mask

A facial mask and anti-reflection technology, applied in skin care preparations, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve skin dehydration, low transdermal absorption rate of nutrients, anti-absorption of non-woven masks, etc. problems, achieve the effect of improving moisture permeability and water retention performance, avoiding skin aging due to oxygen depletion, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

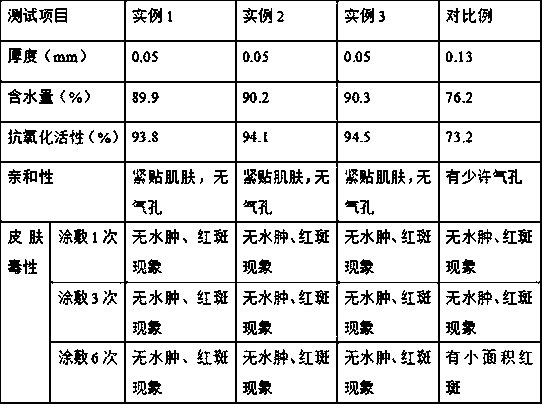

Examples

example 1

[0026] Take fresh rosemary leaves and place them in a freeze dryer, freeze at -20°C for 4 hours, control the freeze-drying pressure to 5 MPa, crush the frozen rosemary leaves, pass through a 200-mesh sieve, and collect rosemary Geranium leaf dry powder, according to the mass ratio of solid to liquid: 1:8, disperse rosemary leaf dry powder in absolute ethanol, stir at a speed of 200r / min, and heat up to 40°C, stir and disperse for 2h, to obtain an extract , put the extract in a high-speed centrifuge at a speed of 3000r / min, centrifuge for 20min, separate and remove the lower sediment, and collect the upper layer; heat the above upper layer in a distillation bottle to 100°C, and reflux for 4h to obtain Rosemary extract, the rosemary extract is subjected to supercritical carbon dioxide extraction, the supercritical extraction pressure is controlled to 20MPa, the extraction temperature is 48°C, the primary separation pressure is 8.5MPa, the secondary separation pressure is 5.0MPa, ...

example 2

[0028] Take fresh rosemary leaves and place them in a freeze dryer, freeze at -25°C for 4 hours, control the freeze-drying pressure to 7MPa, crush the frozen rosemary leaves, pass through a 200-mesh sieve, and collect rosemary Geranium leaf dry powder, according to the mass ratio of solid to liquid: 1:8, disperse rosemary leaf dry powder in absolute ethanol, stir at a speed of 220r / min, and heat up to 45°C, stir and disperse for 3h to obtain an extract , put the extract in a high-speed centrifuge at a speed of 3250r / min, centrifuge for 25min, separate and remove the lower sediment, and collect the upper layer; heat the above upper layer in a distillation bottle to 105°C, reflux for 4h, and obtain Rosemary extract, the rosemary extract is subjected to supercritical carbon dioxide extraction, the supercritical extraction pressure is controlled to 21MPa, the extraction temperature is 49°C, the primary separation pressure is 8.7MPa, the secondary separation pressure is 5.5MPa, and ...

example 3

[0030] Take fresh rosemary leaves and place them in a freeze dryer, freeze at -30°C for 4 hours, control the freeze-drying pressure to 8MPa, crush the frozen rosemary leaves, pass through a 200-mesh sieve, and collect rosemary Geranium leaf dry powder, according to the mass ratio of solid to liquid: 1:8, disperse rosemary leaf dry powder in absolute ethanol, stir at a speed of 250r / min, and heat up to 50°C, stir and disperse for 4h to obtain an extract , put the extract in a high-speed centrifuge at a speed of 3500r / min, centrifuge for 30min, separate and remove the lower layer of sediment, and collect the upper layer; put the above upper layer in a distillation bottle and heat up to 110°C, and reflux for 5h to obtain Rosemary extract, the rosemary extract is subjected to supercritical carbon dioxide extraction, the supercritical extraction pressure is controlled to 22MPa, the extraction temperature is 50°C, the primary separation pressure is 9.0MPa, the secondary separation pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com