Equipment for derusting and synchronously painting ships, and application method thereof

A technology for ships and paints, applied in metal processing equipment, spraying devices, abrasive spraying machine tools, etc., can solve problems such as dust pollution, bad working conditions, etc., and achieve the effect of increasing the striking surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

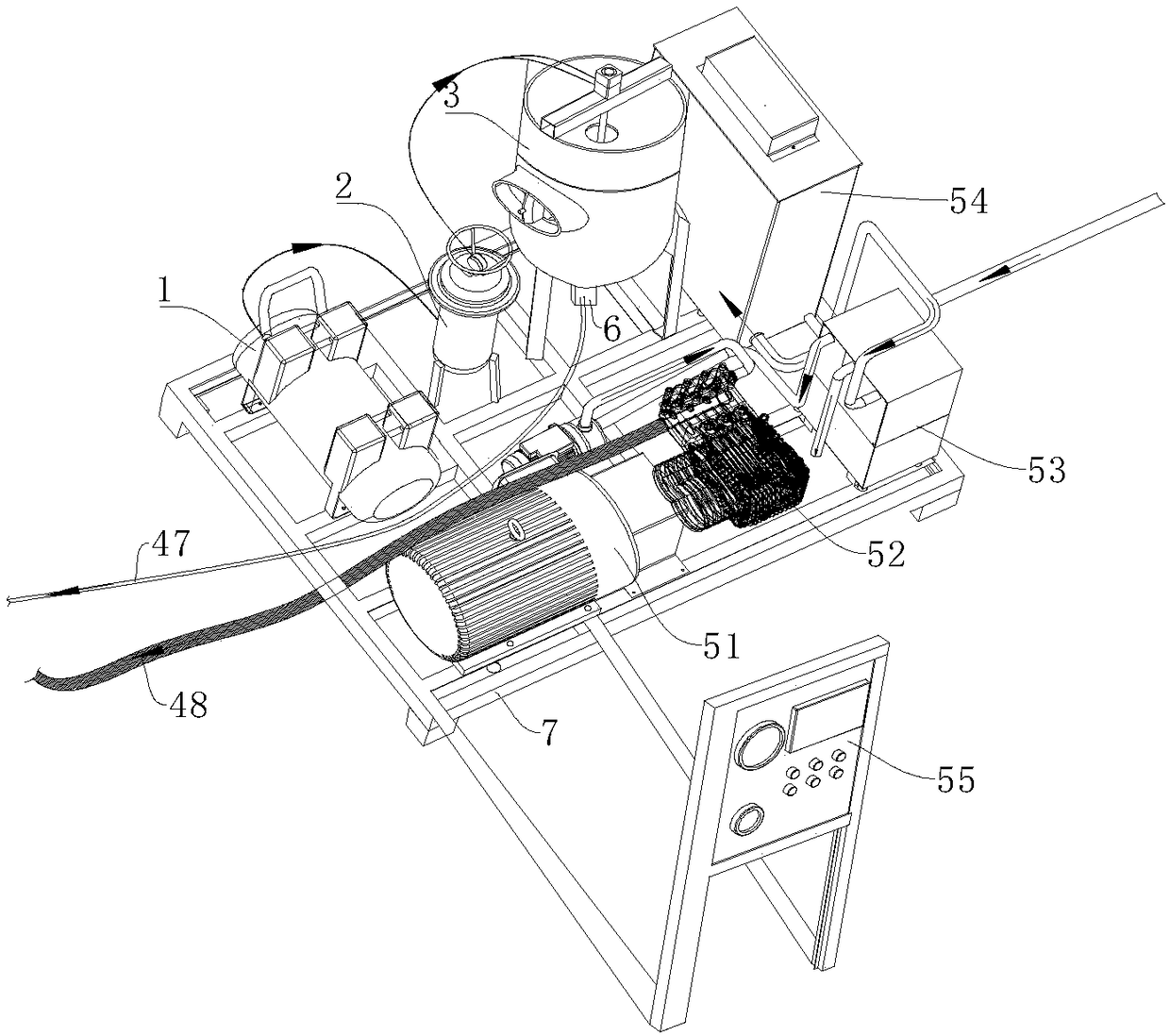

[0027] Such as figure 1 As shown, a ship derusting and simultaneous paint spraying equipment, including sand feeding device, water supply device, wall-climbing robot and spraying device. Sand sending device, water supply device, wall-climbing robot and injection device are installed on the frame 7 and are controlled by controller 55 . The sand sending device includes an air compressor 1, an oil-water separator 2, a tank body 3 and a pneumatic sand valve 6. The pneumatic sand valve 6 is installed at the bottom of the tank body 3. The air compressor 1 supplies air to the pneumatic sand valve 6. Sand delivery port 47 is installed at the sand outlet.

[0028] Water supply device comprises filter 53, water tank 54, drive motor 51 and high-pressure pump group 52, filter 53 is provided with water inlet pipe, filter 53 is communicated with water tank 54, the water inlet of high-pressure pump group 52 is connected water tank 54 by water pipe, high-pressure water pump Driven by a driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com